Shaping device for storage battery electrode group

A technology for shaping devices and storage batteries, which is applied in the manufacture of secondary batteries, battery pack components, circuits, etc., can solve the problems of inability to guarantee consistency, differences in casting and welding quality, and time-consuming, etc. The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

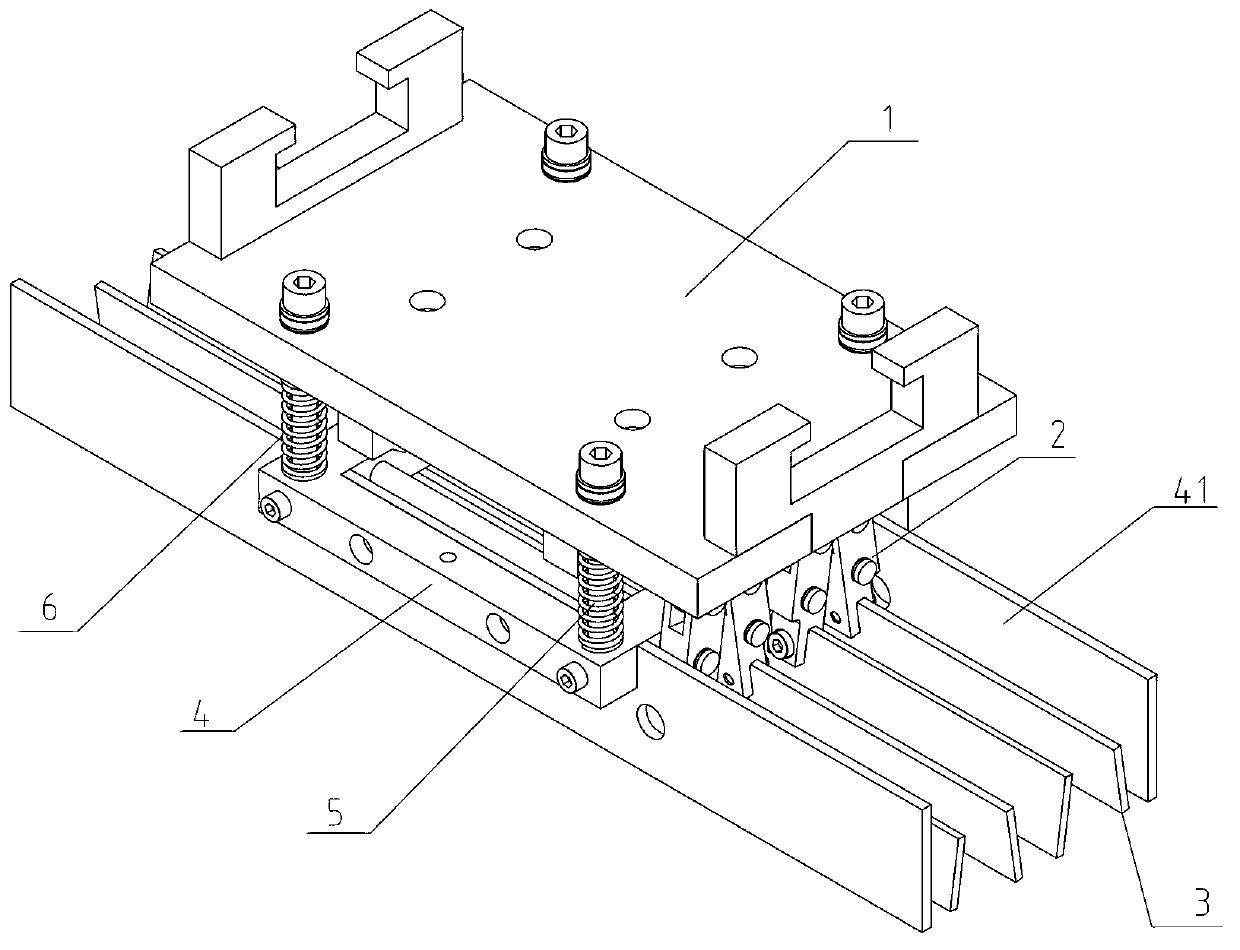

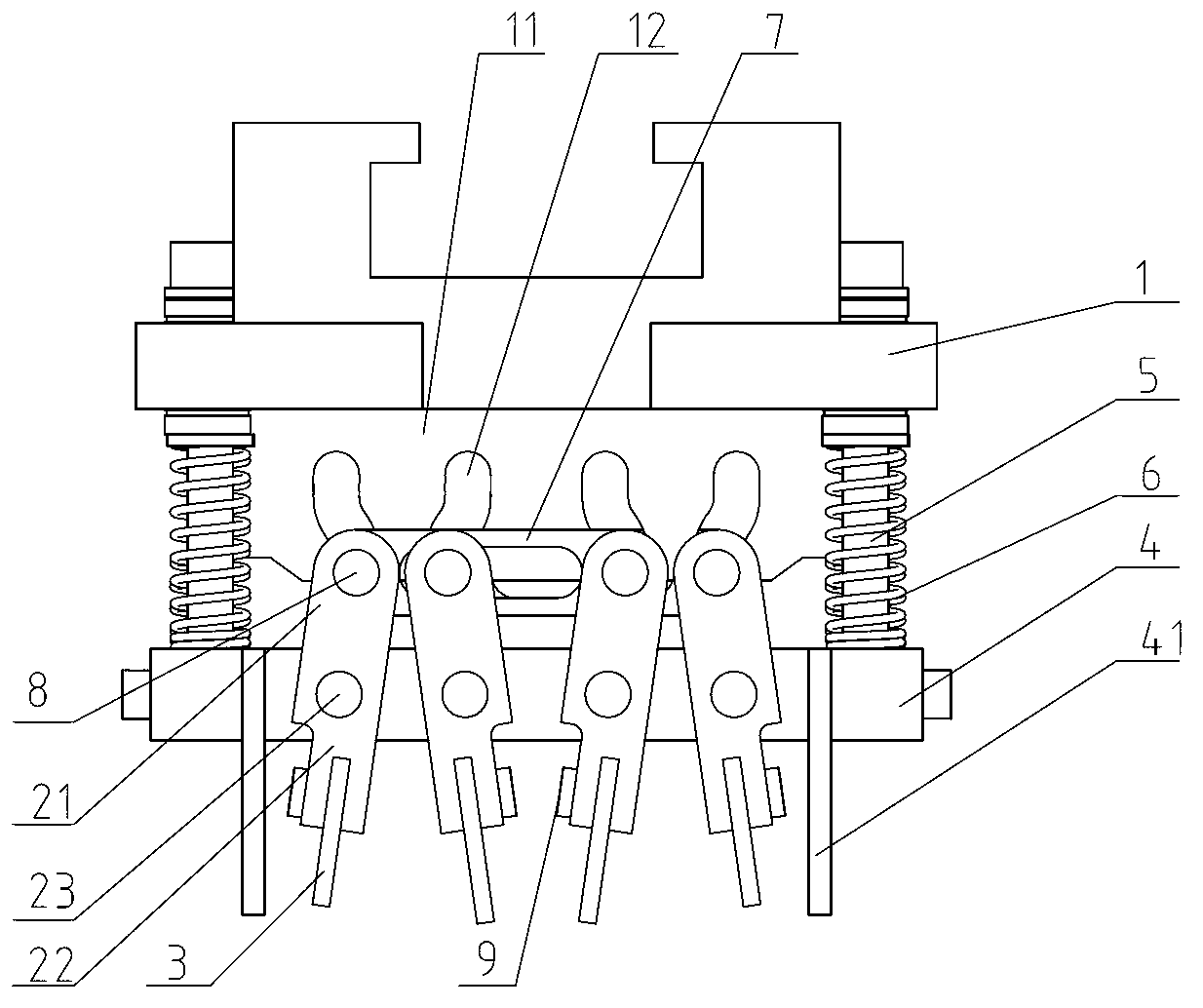

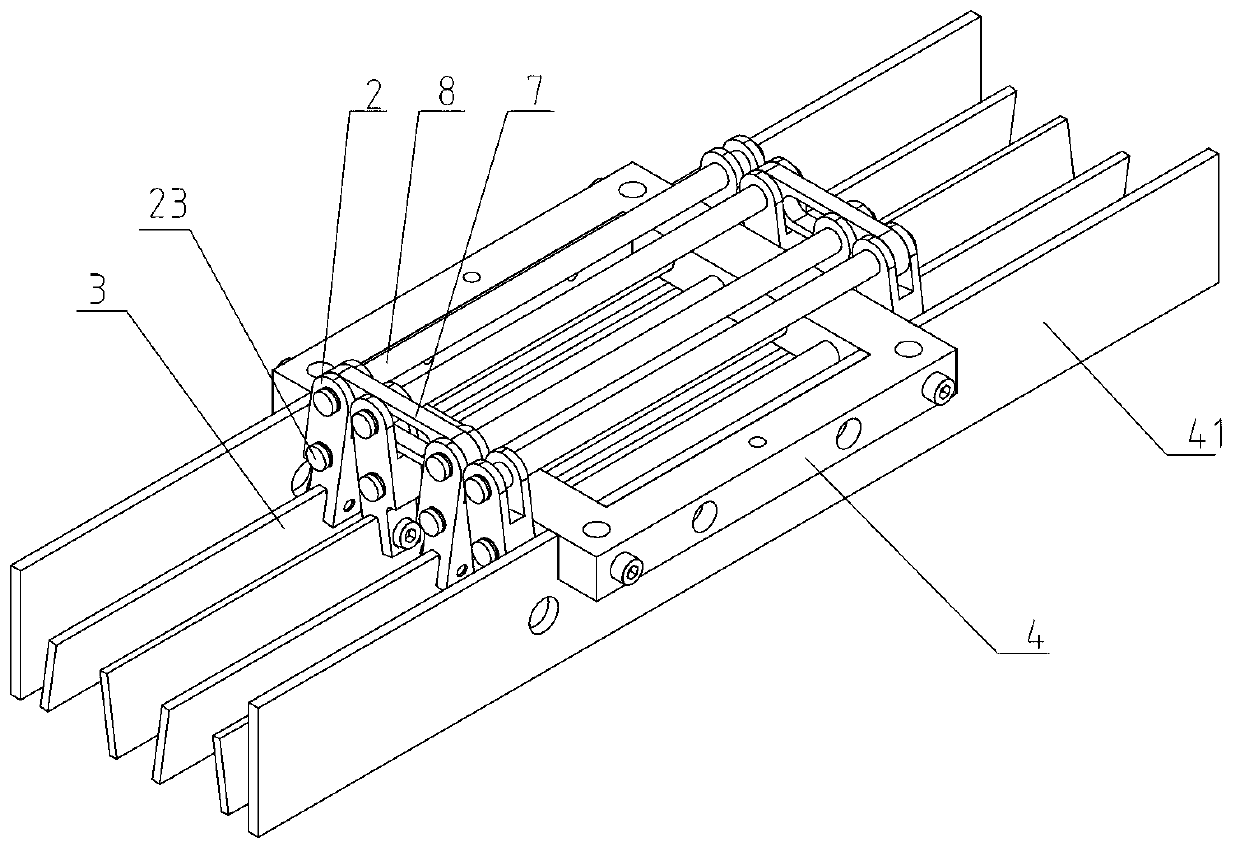

[0025] The invention provides a shaping device for a battery pole group, which includes a shaping part and a driving part. The swing arm is connected with a shaping plate on the follower arm, and the driving part includes a guide plate and a driving member for driving the guide plate to rise and fall. At least one pair of guide grooves corresponding to the rotating bar are arranged on the guide plate, and the main arm and the guide groove They are connected by a linkage rod. When the guide plate descends, the linkage rod moves along the guide groove to drive the adjacent rotating bar to rotate. The main arm is relatively far away, so that the lower driven arms are close to each other, and the shaping plate clamps the side wall of the tab. , during the rising process of the guide plate, the rotating bar is driven to return, the slave arm is relatively separated, and the shaping plate releases the tab.

[0026] The technical solutions of the embodiments of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com