Method and device for melting, atomization and combustion of TNT

A combustion method and combustion equipment technology, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of inventory backlog, high risk, serious environmental pollution, etc., and achieve stable operation, explosion prevention and clean combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

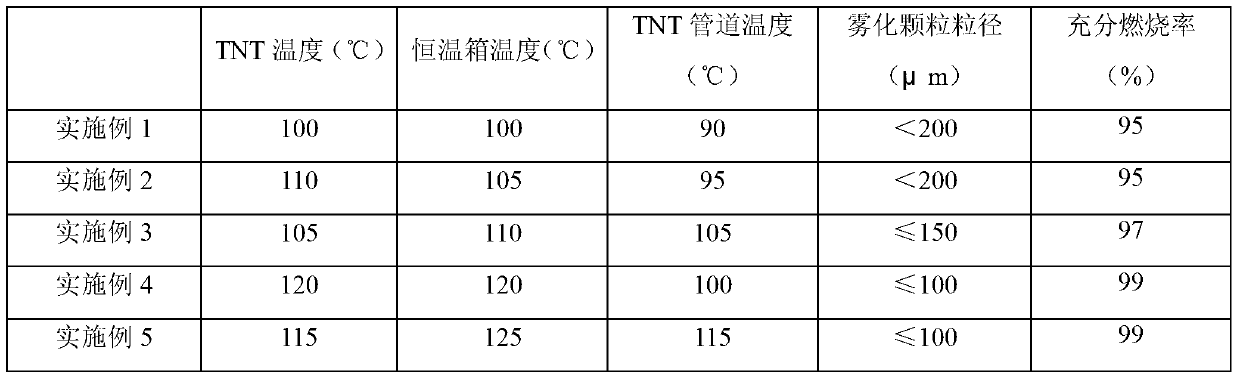

[0040] The present invention will be described in detail below in conjunction with the examples, but they are not further limiting the present invention.

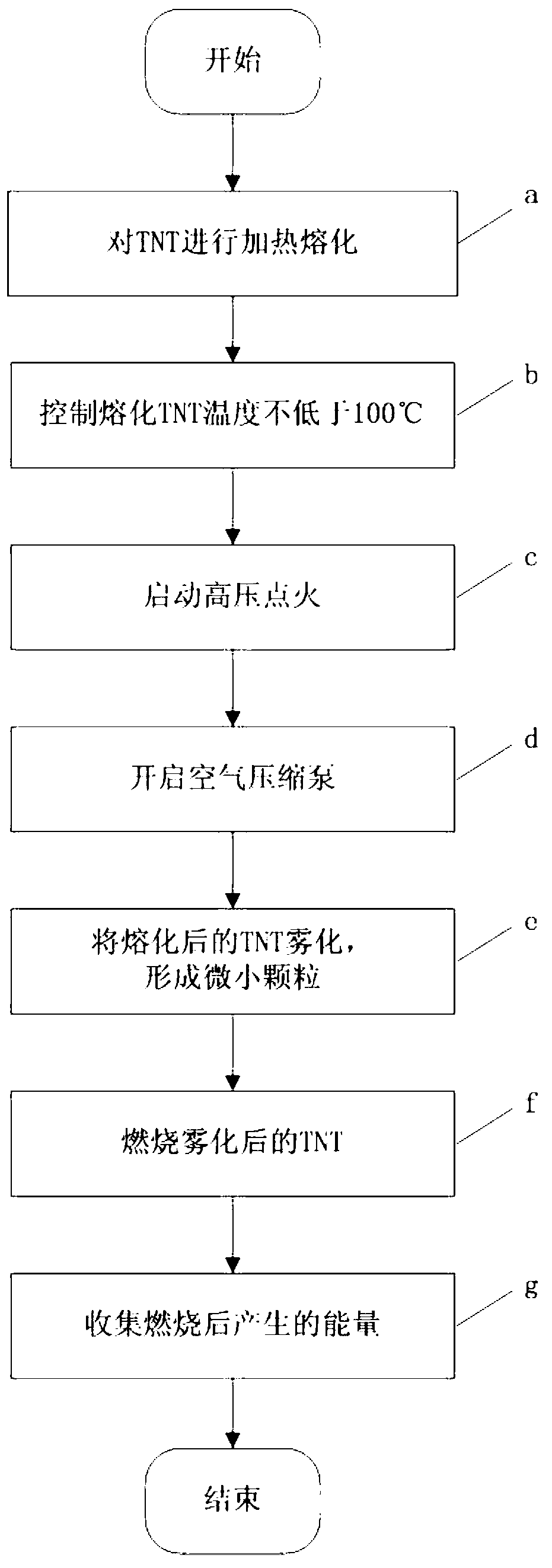

[0041] figure 1 Schematically shows the overall flow chart of the TNT melting atomization combustion method:

[0042] In step a, the TNT is heated and melted; there are many ways to heat and melt the TNT, and the TNT can be heated and melted by steam or oil bath; the melting temperature is controlled at 100-120°C.

[0043] In step b, the temperature of the melted TNT is controlled to be not lower than 100°C; here it means that the temperature before the TNT is atomized is not lower than 100°C;

[0044] In one embodiment of the present application, the melted TNT first enters the incubator 2 through the TNT pipeline 7, the purpose of which is to effectively control the mixing amount of the melted TNT and air, and avoid increasing potential dangers.

[0045] In step c, start the high-voltage ignition; before starting the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com