Vacuum pumping device for interlayer of cryogenic insulation cylinder

A technology of vacuuming device and low temperature insulation, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., and can solve problems such as poor effect, ineffective activation, and long vacuuming time for gas cylinder interlayers. , to achieve good consistency, improve the speed and effect of vacuuming, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

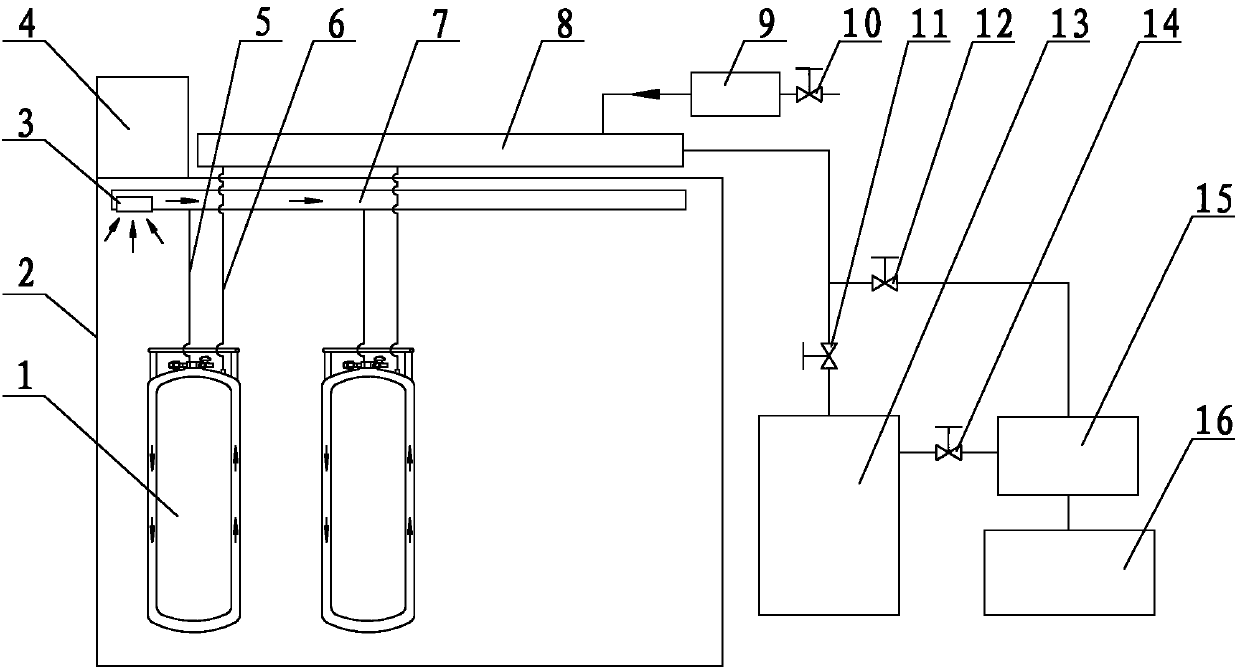

[0022] A low-temperature heat-insulating gas cylinder interlayer vacuum device, which includes a low-temperature heat-insulating gas cylinder 1, a heating oven 2, an internal air circulation fan 3, a burner 4, a heating branch pipe 5, an air extraction branch pipe 6, an internal heating main pipe 7, and an external air extraction Main pipe 8, nitrogen heating device 9, nitrogen replacement valve 10, pneumatic baffle valve I11, pneumatic baffle valve II12, diffusion pump 13, pneumatic baffle valve III14, rotary vane pump 15, Roots pump 16.

[0023] The burner 4 is installed on the upper top of the heating oven 2, and the burner 4 communicates with the inside of the heating oven 2 through a pipeline.

[0024] The low-temperature insulating gas cylinder 1 faces upwards and is placed upright inside the heating oven 2 through the tooling. Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com