Tubular furnace and waste lubricating oil recovery device formed thereby

A technology of waste lubricating oil and recovery device, which is applied in the direction of lubricating compositions, etc., which can solve the problems of coking, low oil yield, and blockage of heating pipes, and achieve the effects of high oil yield, large processing capacity, and uniform heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

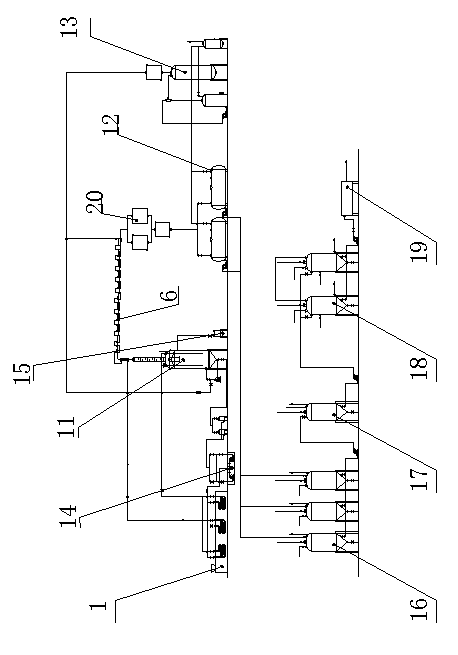

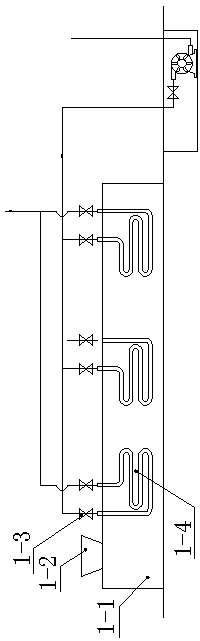

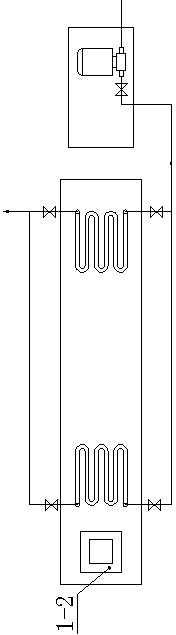

[0012] As shown in the accompanying drawings, the present invention includes a tube furnace 1, waste lubricating oil enters the tube furnace 1 for heating after pretreatment, and the heated oil enters a still 11 and is divided into two parts. Part of the cracked oil enters the oil storage tank 12, and after being filtered by the pickling tank 16, the alkali washing tank 17, the clay tank 18, and the plate and frame filter 19, light fuel oil is obtained, and the other part passes through the residual oil tank 13 for deslagging Finally, heavy fuel oil is obtained, which is characterized in that: the heating tube of the tube furnace 1 is placed horizontally, the tube furnace 1 is connected to the still 11 through the oil pump 14, and the still 11 is connected with an overflow tank 15. The crude oil from the still 11 is sent to the tube furnace through the oil pump 14 for heating. Compared with the traditional single-pot production and vertical tube furnace, this structure has the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com