Cake baking paper support forming machine

A technology of forming machine and paper holder, applied in the direction of paper/cardboard container, envelope/bag manufacturing machinery, container, etc., can solve the problems of unsanitary and inconvenience, and achieve the effect of remarkable progress and outstanding substantive characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

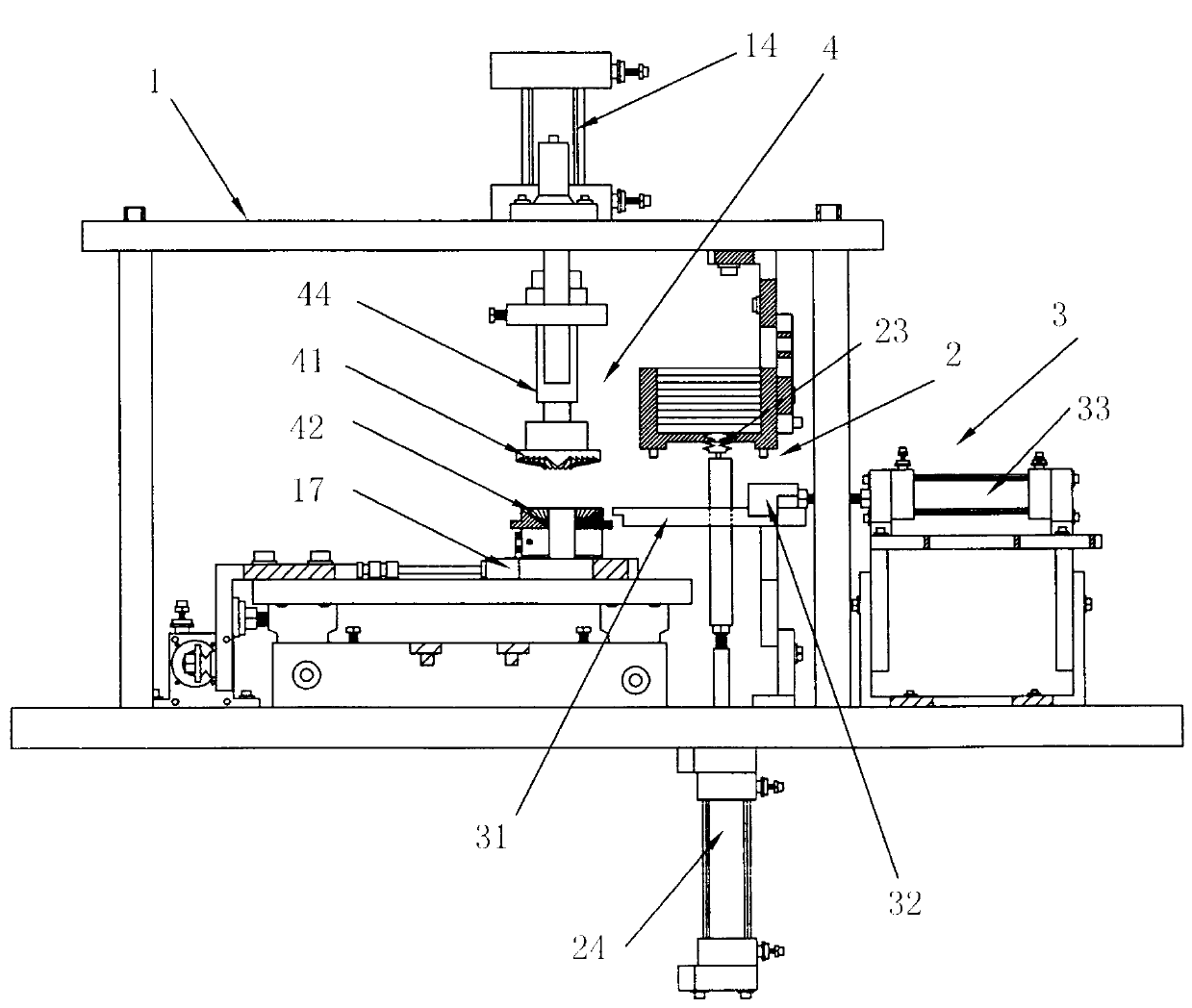

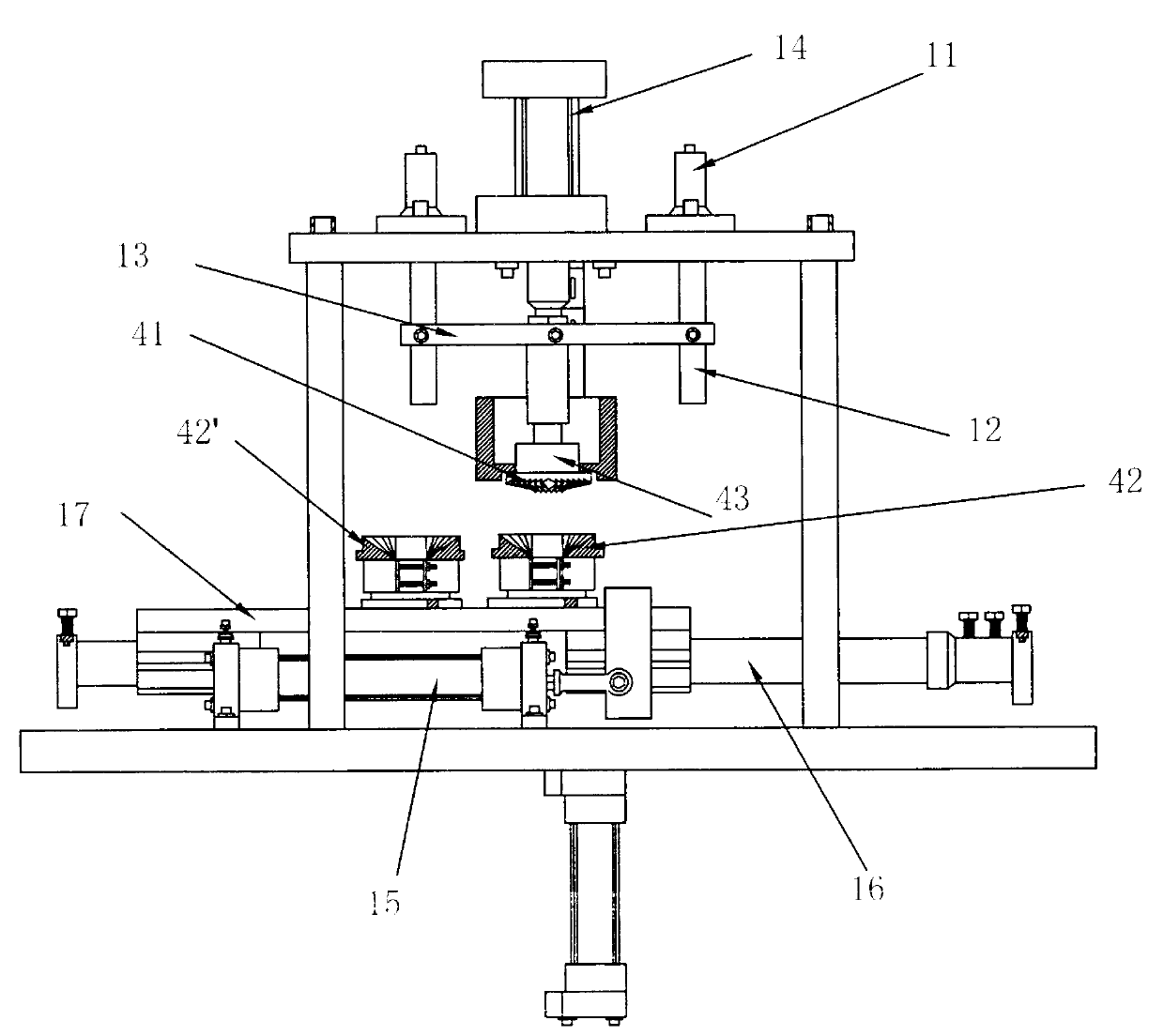

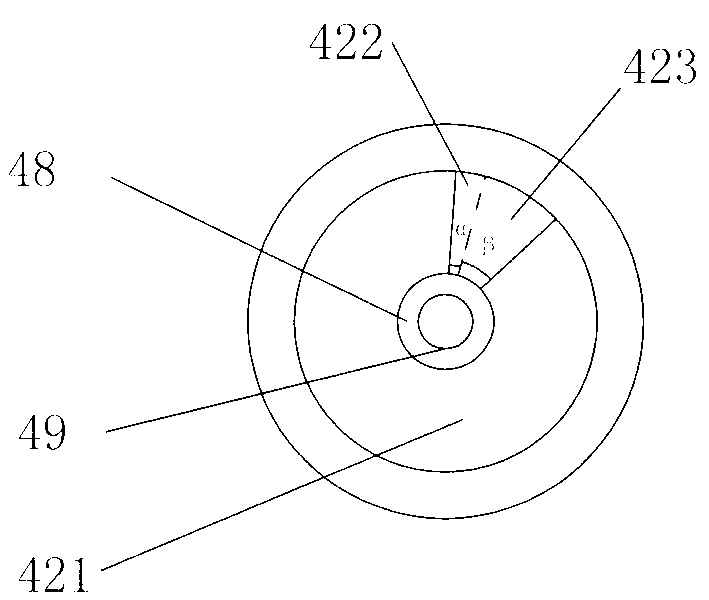

[0028] Referring to the drawings, the cake tray forming machine in this embodiment includes a frame 1 on which a paper feeding mechanism 2, a paper feeding mechanism 3, and a paper tray stamping and forming mechanism 4 are provided. The paper tray punching and forming mechanism 4 includes a pair of matching upper mold 41 and lower mold 42. The upper mold and the lower mold are provided with mutually matching and matching mold surfaces. The paper sheet is pressed and matched by the upper and lower molds. Indentation treatment is carried out. The indentation treatment is the pre-treatment of the cup wall forming; the upper and lower mold surfaces can be provided with radial arc strips that cooperate with each other, and the cross section of the cup wall after the finished product is continuous arc or continuous Tooth profile, see attached Picture 9 ; In this embodiment, the mold surface 421 of the lower mold 42 is recessed (low center, high periphery), and the mold surface 421 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com