Slewing bearing ferrule circular degree error automatic detection and correction device

A roundness error and slewing bearing technology, which is applied in the field of automatic detection and correction devices for roundness errors of slewing bearing rings, can solve problems such as potential safety hazards, repeated corrections, and breakage of slewing bearing rings, so as to improve running stability, The effect of increasing the service life and reducing the roundness error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

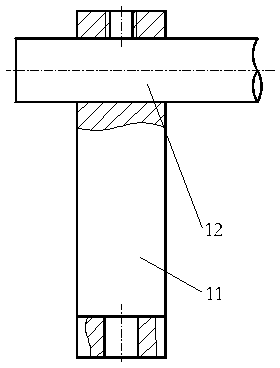

Image

Examples

Embodiment Construction

[0021] The working process of the device of the present invention is as follows:

[0022]1. When detecting the roundness error of the slewing bearing ring, the oil cylinders of the first lifting and anti-warping mechanism 5A, the second lifting and anti-warping mechanism 5B, and the third lifting and anti-warping mechanism 5C are in the lowered position. The anti-warping pressure plate on the lifting and anti-warping device, the slewing support is supported by the first ferrule support and rotary drive mechanism 2A, the second ferrule support and rotary drive mechanism 2B, the third ferrule support and rotary drive mechanism 2C and It is driven to rotate, and after one rotation, the roundness error value, correction position and correction stroke can be obtained by the data acquisition operation and display system.

[0023] 2. After the roundness error detection is completed, the first ferrule support and rotary drive mechanism 2A, the second ferrule support and rotary drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com