Transparent electrode substrate, method for producing same, photoelectric conversion device, method for producing same, and photoelectric conversion module

A technology of transparent electrodes and manufacturing methods, applied in cable/conductor manufacturing, circuits, photovoltaic power generation, etc., can solve the problem of not considering transmittance, etc., and achieve the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024] figure 1 It is a cross-sectional view schematically showing a method of manufacturing a transparent electrode and a method of manufacturing a photoelectric conversion device according to Embodiment 1 of the present invention. Here, an aluminum (Al) thin film will be described as an example of a dopant-containing thin film composed of a dopant-containing material. First, if figure 1 As shown in (a), an aluminum thin film 2 and a zinc oxide (ZnO)-based thin film 3 are sequentially stacked on a light-transmitting insulating substrate 1 . As the translucent insulating substrate 1 , various translucent insulating substrates such as glass, transparent resin, plastic, and quartz are used.

[0025] For the zinc oxide-based thin film 3 , for example, a zinc oxide film is used. Zinc oxide is one of transparent conductive oxides (TCO: Transparent Conductive Oxide) generally used as a transparent electrode material. Furthermore, the zinc oxide-based thin film 3 has zinc oxide a...

Embodiment approach 2

[0052] Image 6 It is a cross-sectional view schematically showing a method of manufacturing a transparent electrode and a method of manufacturing a photoelectric conversion device according to Embodiment 2 of the present invention. The manufacturing method of the transparent electrode of Embodiment 2 is different from the manufacturing method of the transparent electrode of Embodiment 1 in that the etching step is performed both before and after the thermal diffusion step. Hereinafter, the same symbols are assigned to the same components as in Embodiment 1. FIG.

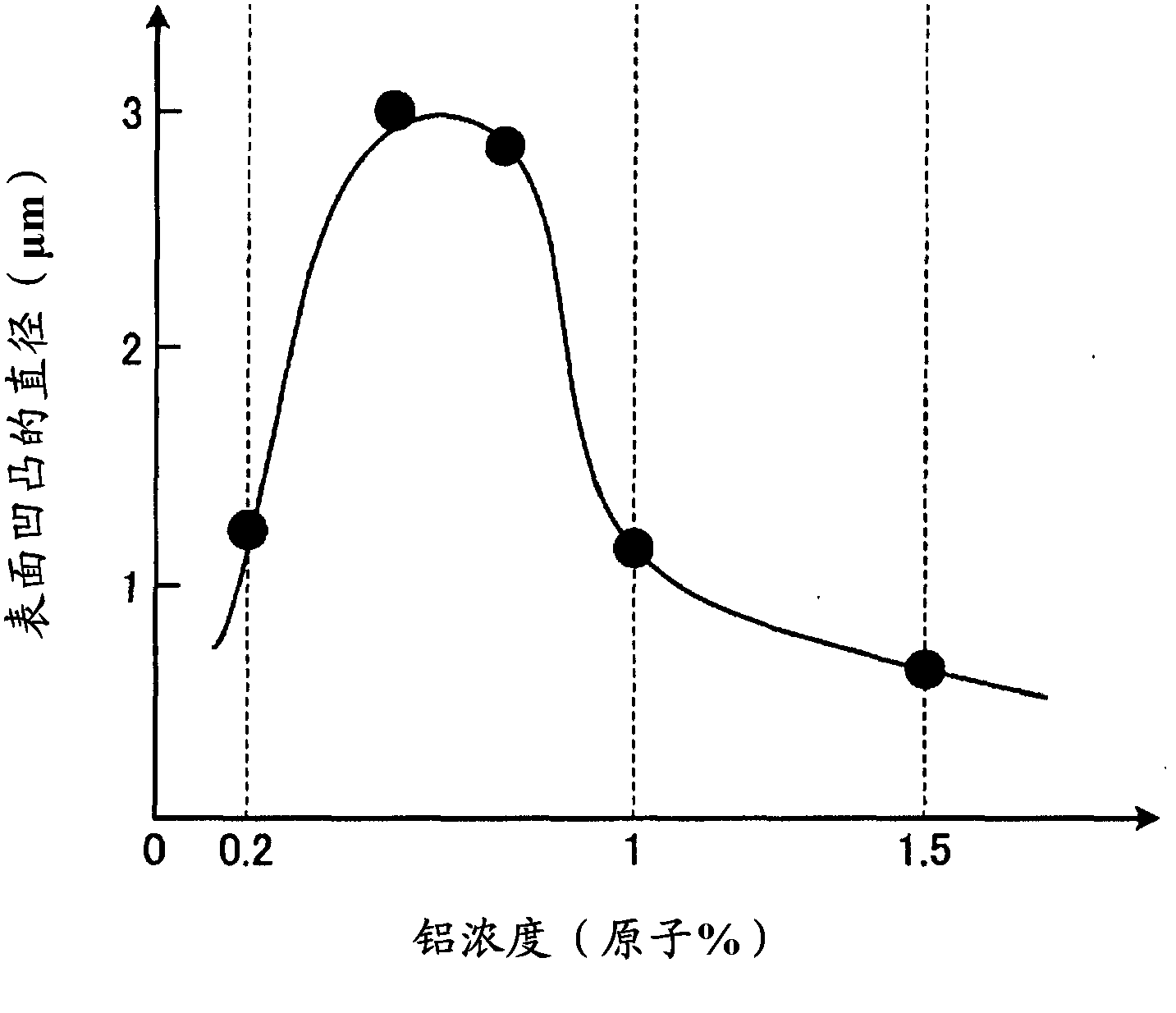

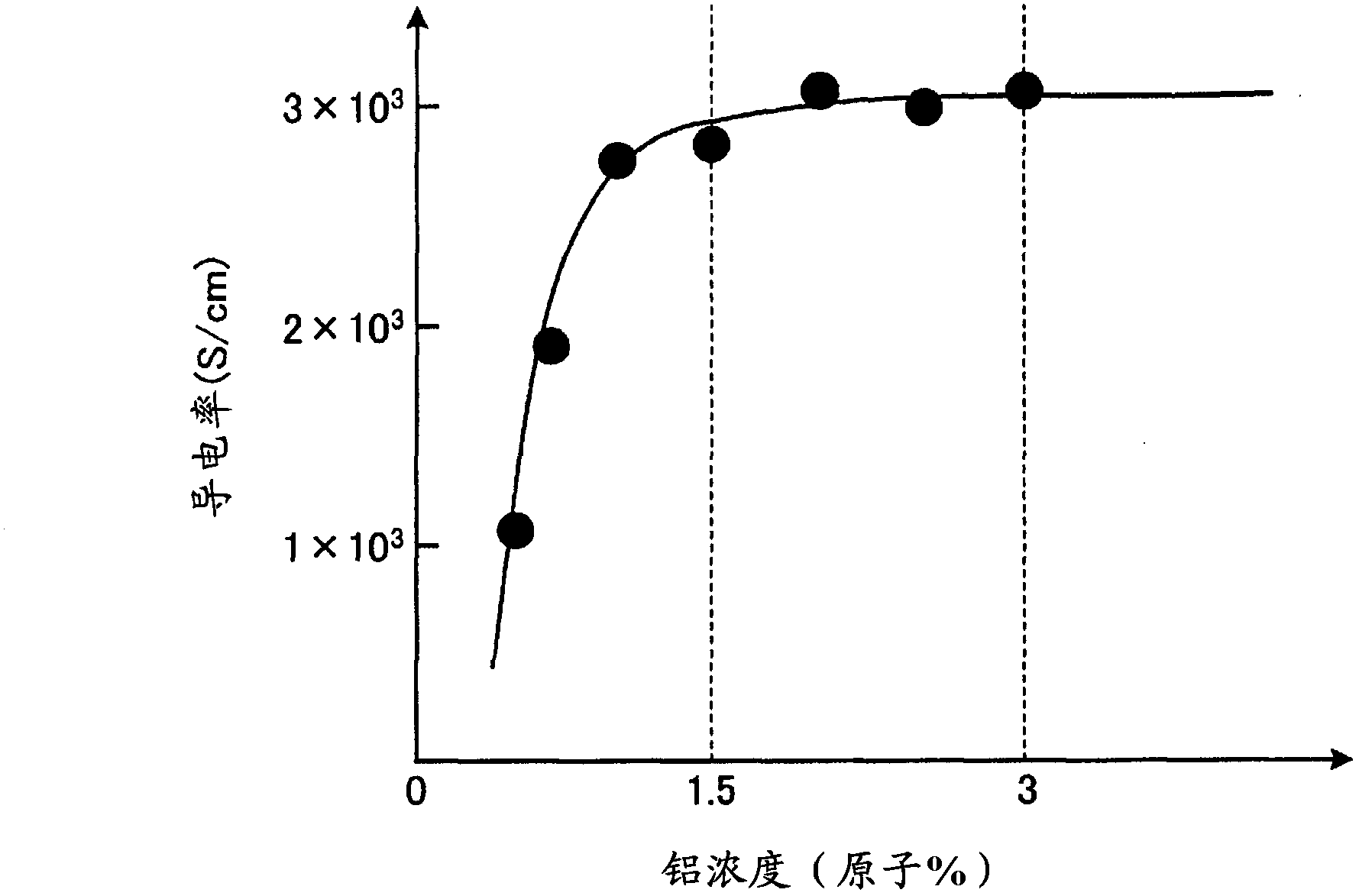

[0053] It has been reported that the shape of the surface irregularities formed on the surface of the zinc oxide thin film by etching is based on figure 2 The aluminum concentration in the zinc oxide-based thin film shown, and the temperature at the time of film formation of the zinc oxide-based thin film, and the thermal history of the film such as heat treatment vary. In Embodiment 2, a higher light-scattering ...

Embodiment approach 3

[0072] Figure 7 It is a cross-sectional view schematically showing a method of manufacturing a transparent electrode and a method of manufacturing a photoelectric conversion device according to Embodiment 3 of the present invention. The method for manufacturing a transparent electrode according to Embodiment 3 differs from the method for manufacturing a transparent electrode according to Embodiment 1 in that an etching step is omitted by using MOCVD in forming the zinc oxide-based thin film. Hereinafter, the same reference numerals are attached to the same components as in the first embodiment.

[0073] First, if Figure 7As shown in (a), after an aluminum thin film 2 is formed on a light-transmitting insulating substrate 1 , a zinc oxide-based thin film 6 having surface irregularities is stacked by MOCVD. Furthermore, the translucent insulating substrate 1, the aluminum thin film 2, and the zinc oxide-based thin film 6 can be selected from various materials described in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com