Micro electromechanical resonator based on structural self-excited vibration principle

A micro-electromechanical resonator and self-excited vibration technology, which is applied to electrical components, impedance networks, etc., can solve problems such as increased amplitude, achieve the effects of increasing the resonance amplitude, simplifying the structure, and eliminating the risk of short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

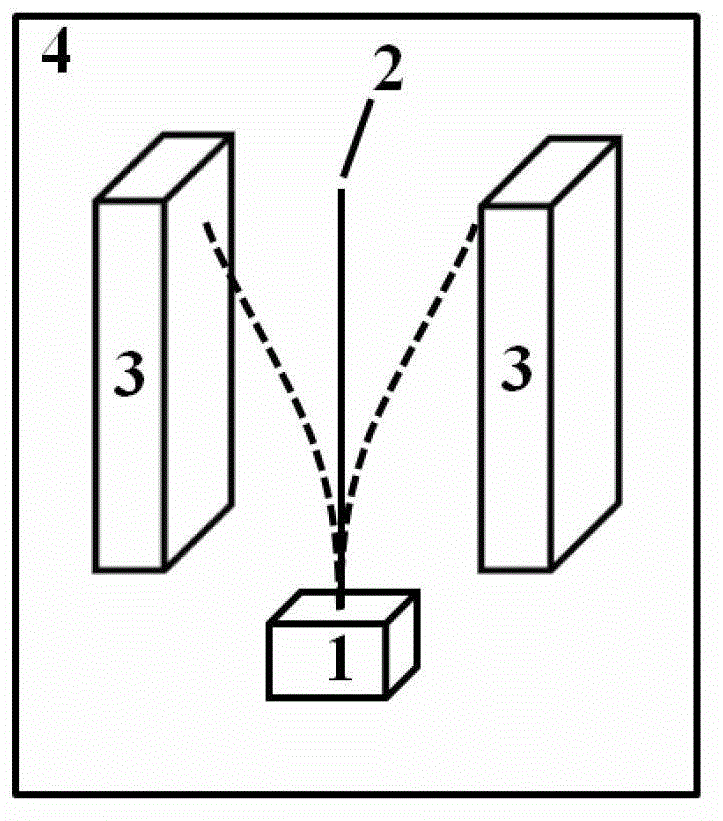

[0028] Such as figure 1 As shown, the present invention provides an implementation example of a MEMS resonator based on the principle of structural self-excited vibration, including: an insulating support base 1 (length, width and height are 2mm*2mm*1mm), the insulating support base is not Connected to any electrode and not grounded, that is, the potential is floating; a conductive microbeam 2 (cylindrical, 10-11mm long, 10.5mm in this embodiment, 25-26μm in diameter, 25.4μm in this embodiment), the conductive microbeam One section of the beam 2 is fixed on the above-mentioned insulating support base 1, and the other end is suspended horizontally; two DC driving electrodes 3 (cuboid, with a length, width and height of 15mm*4mm*2mm), and the space between the two DC driving electrodes 3 is kept A certain distance (4-5mm, 4.5mm is taken in this embodiment), and one of the electrodes is connected to a positive DC voltage (0~+600V), and the other electrode is connected to a negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com