Vacuum bubble switching mechanism and on-load tap-changer

A switching mechanism and on-load tapping technology, which is applied in transformers, electrical components, variable inductors, etc., can solve problems such as longitudinal errors, high structural precision, and difficult installation, so as to improve accuracy, improve motion accuracy, The effect of improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

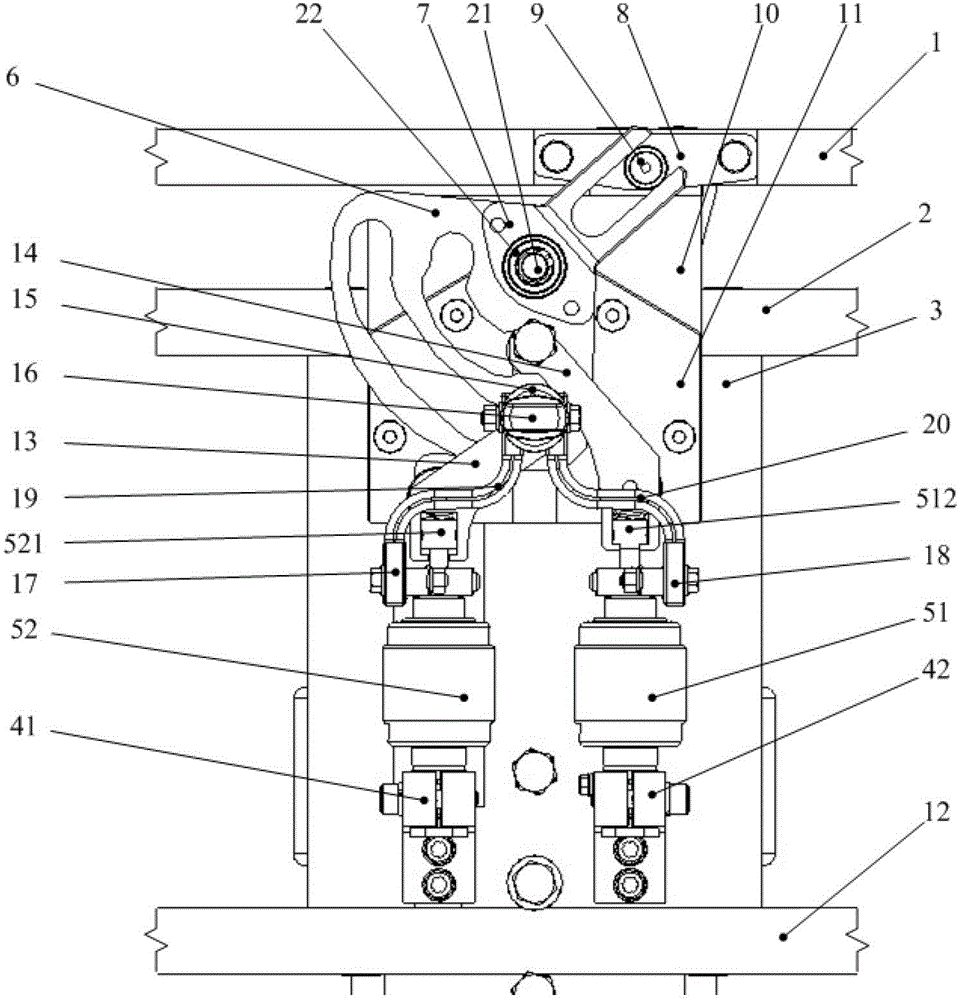

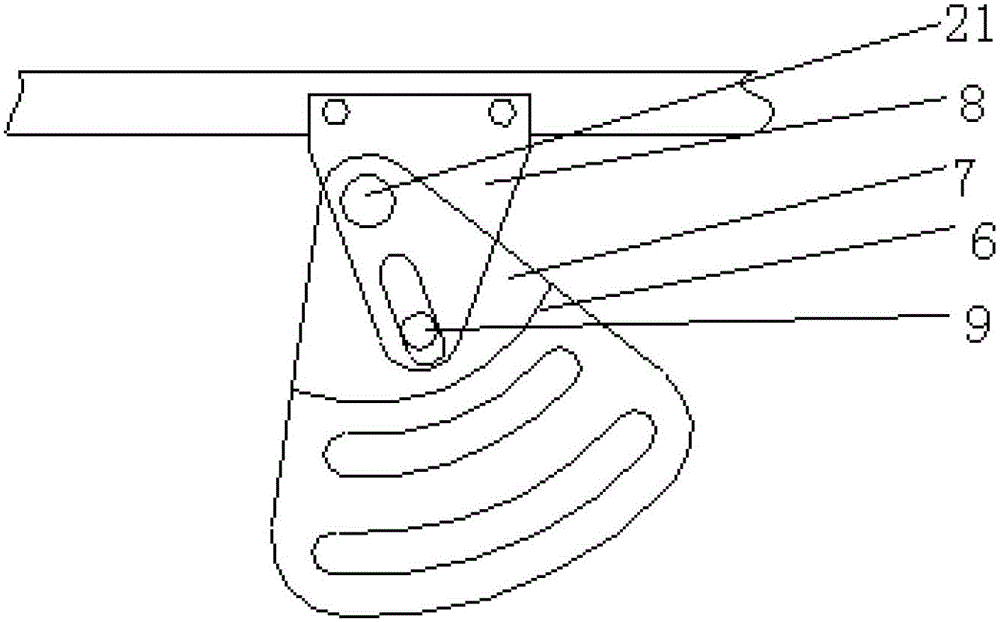

[0021] Such as figure 1 As shown, the vacuum bubble switching mechanism described in this embodiment includes a guide plate, a switching block 8, a shift fork 7, a profiling plate 6 and two vacuum bubble structures, the shift fork 7 is provided with a bearing mounting hole, and a rolling bearing is installed in it. 22. A hole is provided on the guide plate 11, and a bolt 21 is fixed in the hole. The rolling bearing 22 is installed on the bolt 21 together with the shift fork 7, so that the shift fork 7 can rotate around the fixed bolt. The profiling plate 6 is fixed on the shift fork 7 by bolts, and can rotate with the shift fork 7 rotation. Switch shift block 8 is installed on one side of slide plate 1, and a roller bearing 9 is installed on it, places shift fork 7 fork-like grooves, always contacts with fork-like groove one side.

[0022] The working process of this embodiment is: when the slide plate 1 makes a horizontal step movement under the action of the external power ...

Embodiment 2

[0027] Present embodiment except following feature other structures are with embodiment 1:

[0028] In this embodiment, the switching block is fixed on the side of the slide plate, and the shift fork 7 is mounted on the bolt 21 through a rolling bearing, and a long slot is opened on it, in which the roller bearing 9 on the switching block 8 is placed. The profiling plate 6 and the shift fork 7 are welded as one. The working method of this structure is: when the slide plate 1 slides to the left or right, it drives the switching block 8 and the roller bearing 9 to move to the left or right, and at the same time, the shift fork 7 is moved to the left or right by the roller bearing 9 Swing to the right, drive the profiling plate on it to swing around the latch 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com