A circuit portion of a semi-automatic wood children's bed trademark thermoprinting machine

A hot stamping machine, semi-automatic technology, applied in the sequence/logic controller program control, electrical program control and other directions, can solve the problems of inapplicable hot stamping trademarks, heating interrupt hot stamping temperature, etc., to achieve automatic control of hot stamping time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

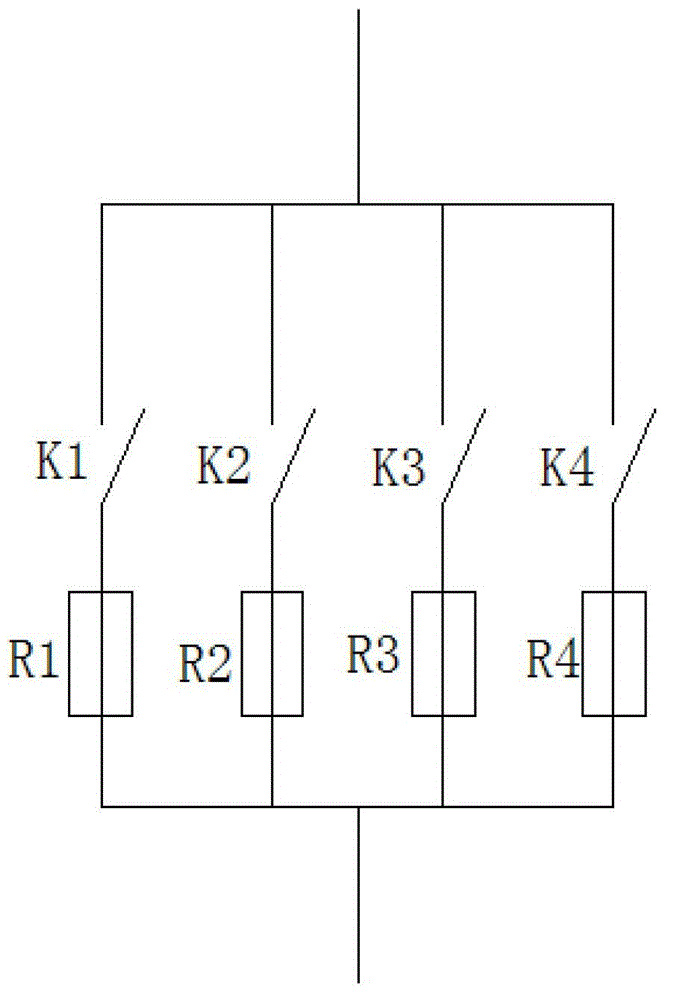

[0016] Such as figure 1 , 2 As shown, the circuit part of a semi-automatic wooden crib trademark hot stamping machine includes six branches connected in parallel with each other in turn, the six branches are connected to 220V AC voltage, and the six branches are connected to the positive and negative poles of the AC voltage. An air switch K is respectively connected between them, wherein branch 1 includes a temperature controller WK, branch 2 includes electric heating rods R connected in series and the main contact of contactor C1, and the main contact of contactor C1 The main contact of contactor C2 is also connected in parallel. Branch 3 includes the coil of contactor C1 connected in series and the normally closed contact of temperature controller WK. Branch 4 includes the coil and pin of contactor C2 connected in series. The normally open contacts of the pedal switch and the temperature controller WK are connected in parallel with the normally closed contacts of the time r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com