Pure-hydrostatic tube mill

A pure static pressure and tube mill technology, applied in cement production, grain processing, etc., can solve the problems of short life of sliding shoe bearings, frequent tile burning, high wear and power consumption, etc., and achieve strong load performance and self-calibration performance Good, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

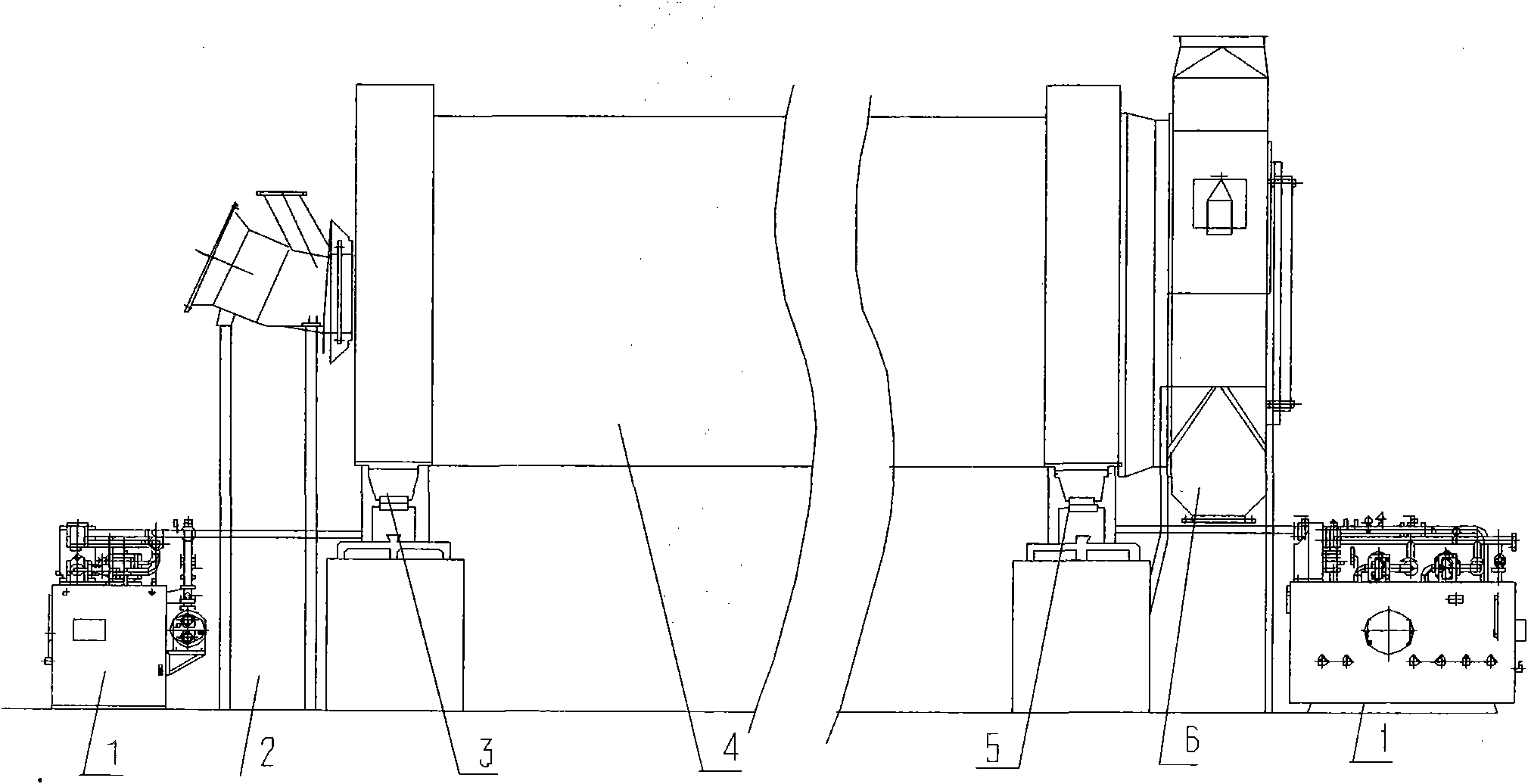

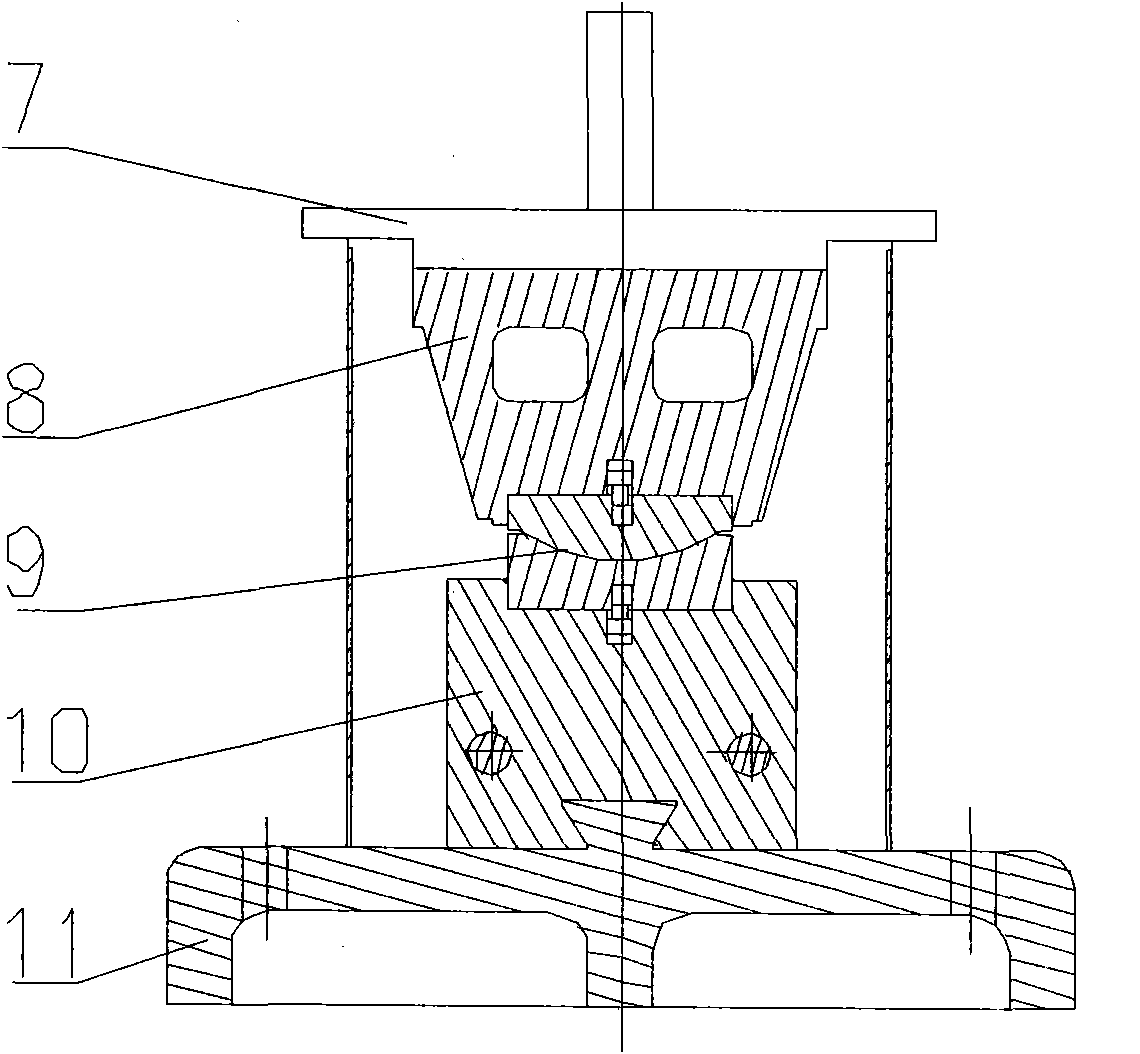

[0035] Such as figure 1 , 2a , 2b, and 3 show: the pure static pressure tube mill, including: feeding device, feed end support system, rotary part, discharge end support system, discharge device and lubrication and control station, the rotary part The support system at the feed end is equipped with a flat seat type pure static pressure sliding shoe moving bearing structure; the discharge end support system of the rotary part is equipped with a flat seat type pure static pressure sliding shoe axial thrust bearing structure; the flat seat The pure static pressure sliding shoe moving bearing structure and the flat seat type pure static pressure sliding shoe axial thrust bearing structure are lubricated by the high pressure oil from the lubrication and control station to make the cylinder slip ring and the sliding shoe support A thicker oil film is formed between the tiles to realize full liquid lubrication.

[0036] 1. Combination figure 1 , The pure static pressure tube mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com