Method and device for conveying compressed gas

A gas and compression stage technology, which is used in the field of conveying compressed gas and devices, and can solve problems such as unused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

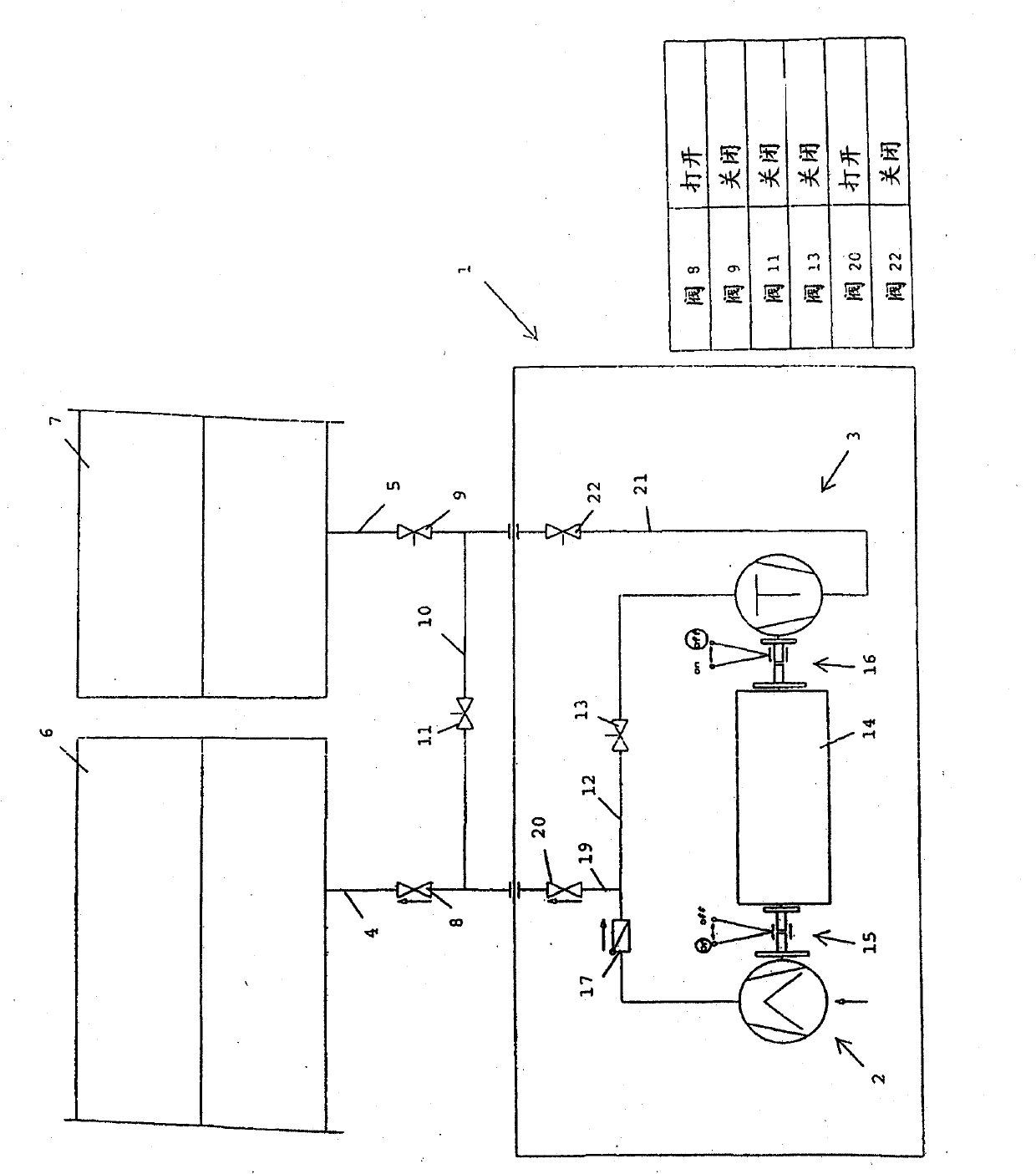

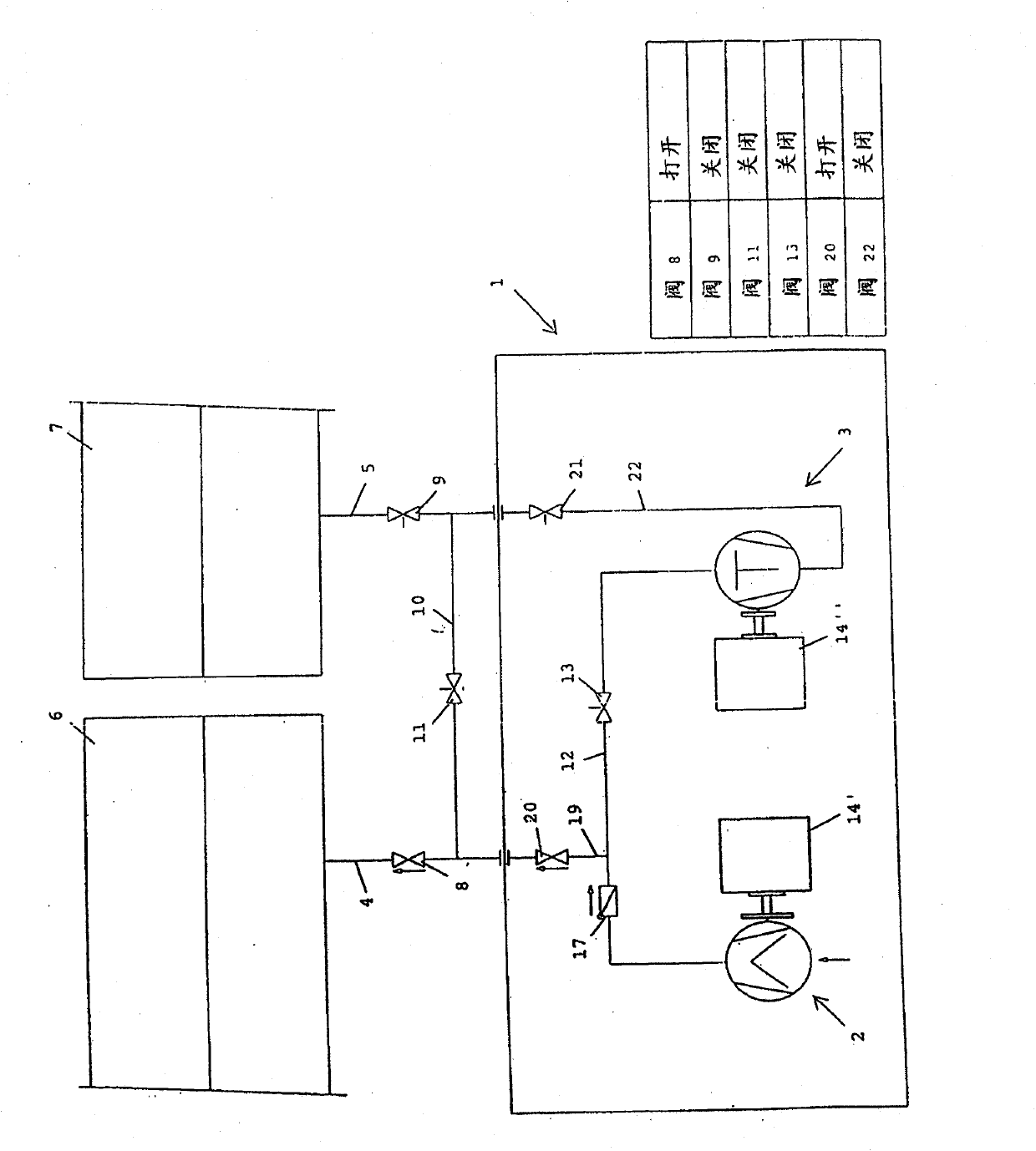

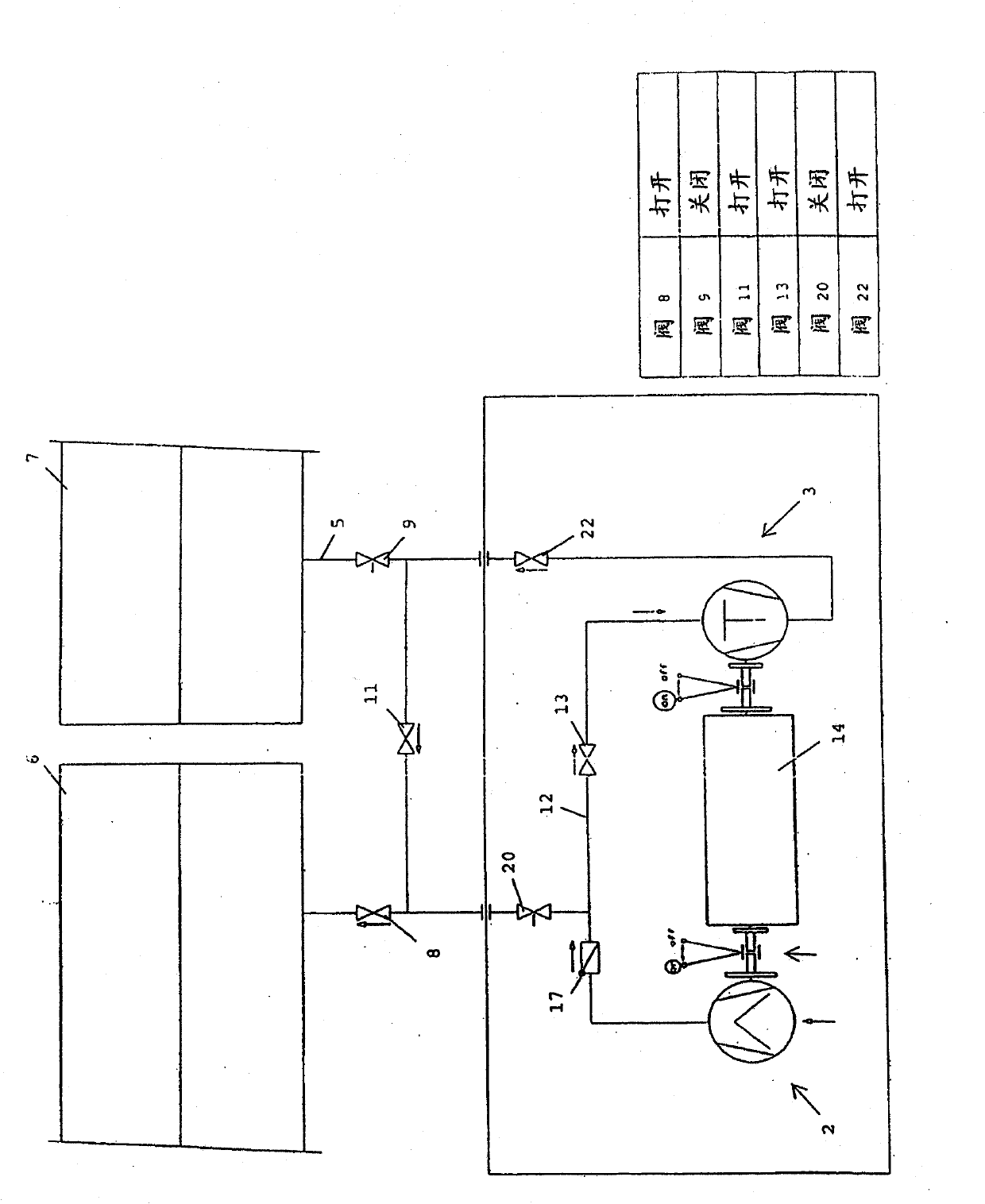

[0028] figure 1 and Figure 1a A compressor 1 with a low-pressure stage 2 and a high-pressure stage 3 is shown in . The compressor 1 is connected via a first gas supply line 4 to a first line section 6 and via a second gas supply line 5 to a second line section 7 . A shut-off valve 8 or 9 is provided in each gas delivery line 4 , 5 so that the intake and exhaust flow through the two gas delivery lines 4 , 5 can be selectively controlled. The two gas supply lines 4 , 5 are connected to one another via a bypass line 10 , which also has a shut-off valve, ie, a bypass valve 11 .

[0029] The two compression stages, ie the low-pressure compression stage 2 and the high-pressure compression stage 3 , are connected to each other via a compression line 12 , in which a shut-off valve, ie, a compression valve 13 , is likewise provided. In the illustrated embodiment, a screw compressor 2 is provided as the low-pressure compression stage 2 and a reciprocating piston compressor is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com