Oil Pre-treatment and Degassing Method for Gas Chromatographic Analysis of Transformer Insulating Oil

A transformer insulating oil and chromatographic analysis technology, which is applied in the field of insulating oil gas chromatography analysis, can solve the problems that affect the accuracy of the analysis results, the analyst's work intensity is high, and the operation process is complicated, so as to reduce the artificial reading error and improve the quality of the oil. Gas rate, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

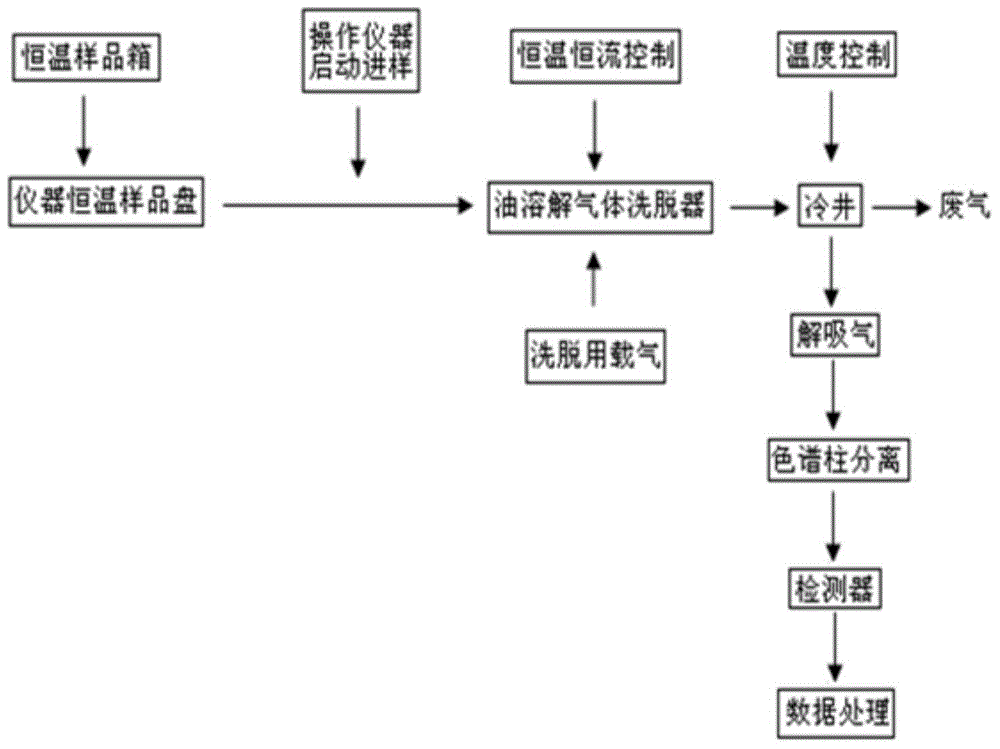

[0035] A kind of oil product pretreatment degassing method that is used for transformer insulating oil gas chromatographic analysis, such as figure 1 As shown, the equipment used in the method includes a constant temperature sample box, an instrument constant temperature sample tray, an oil-dissolved gas elutor, a cold trap, a chromatographic column, a detector, and a control computer for data processing. The steps of the method are as follows:

[0036] (1) Retrieve the transformer insulating oil sample at the substation;

[0037] (2) put the retrieved sample into a constant temperature sample box for constant temperature, and the constant temperature sample box is a common constant temperature sample box sold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com