Full-loop alternating-current self-test high-voltage electroscope

An electroscope device and a full-circuit technology, applied in the direction of measuring devices, measuring current/voltage, measuring electrical variables, etc., can solve problems such as long response time, misjudgment of no electricity in high-voltage equipment, and high starting voltage of electroscopes, so as to improve sensitivity , ensure safe operation, and reduce the effect of response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

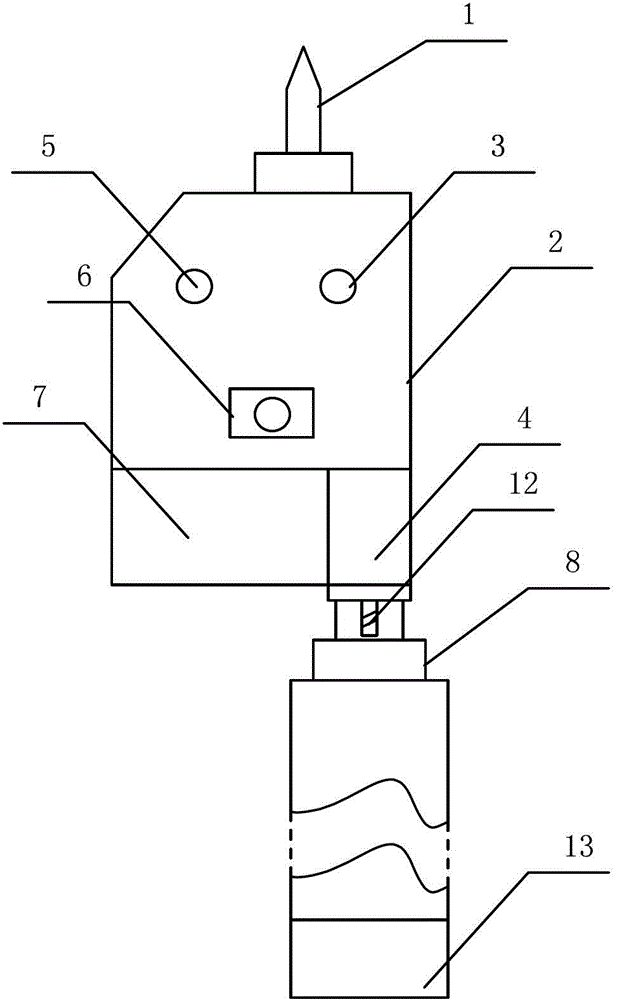

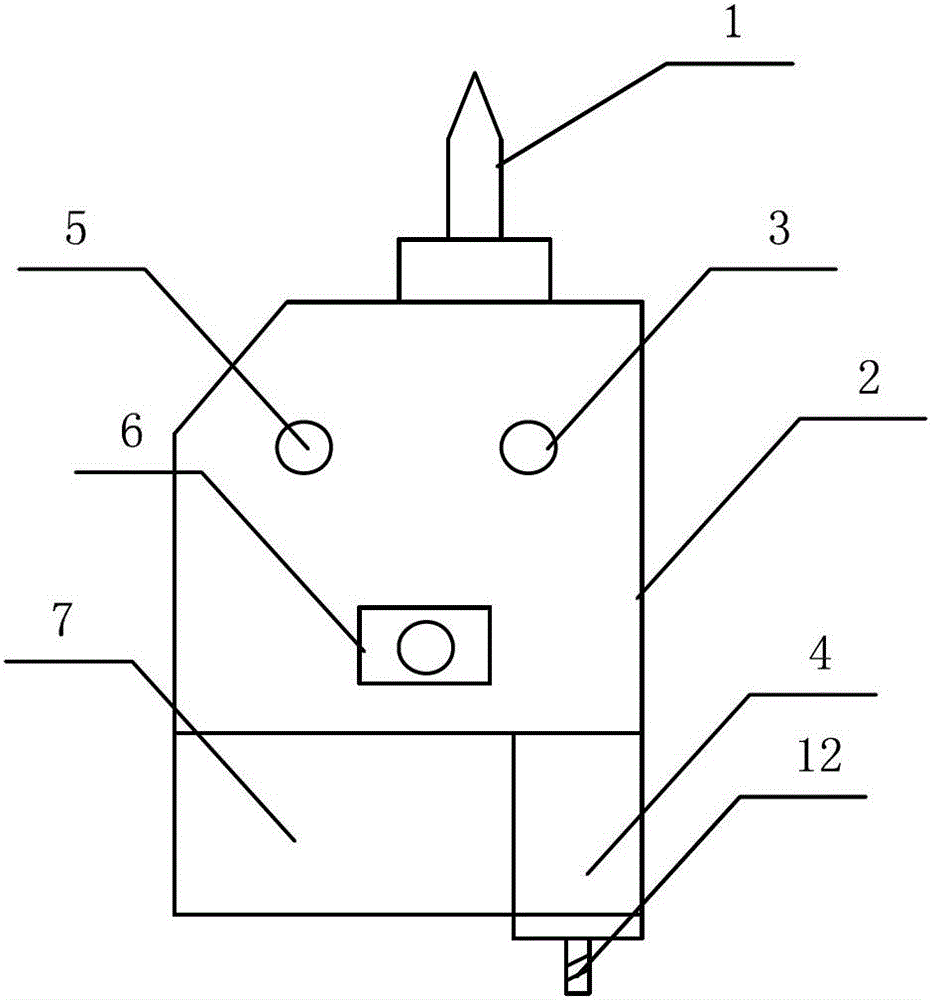

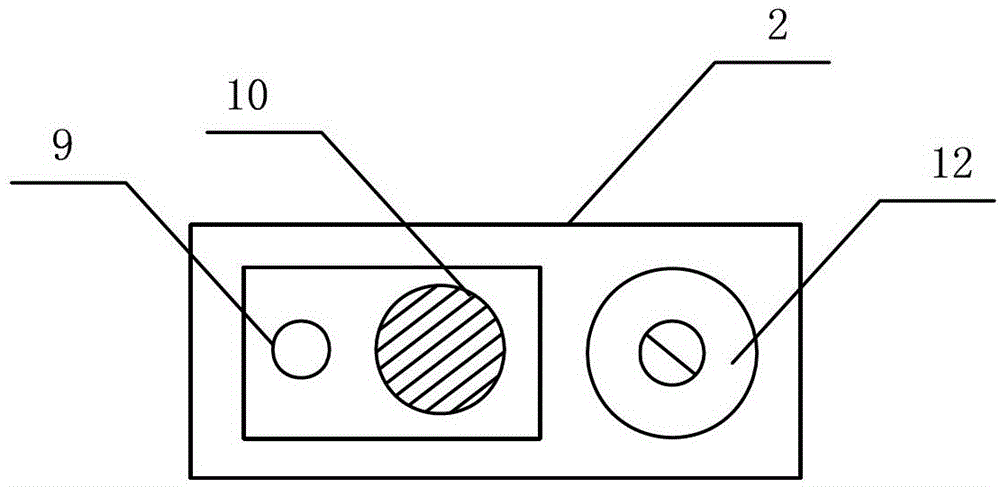

[0015] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a full-circuit AC self-inspection high-voltage electroscope device of the present invention includes a high-voltage electroscope body and a multi-section telescopic insulating rod 8, and the high-voltage electroscope body includes a high-voltage electroscope probe 1, a housing 2, a full Loop self-inspection indicator light 3, DC power supply compartment 4, undervoltage indicator light 5, self-inspection button switch 6, sound and light generator 7 and full-circuit self-inspection electric circuit 11, the front end of the positive end surface of the housing 2 is set There is an undervoltage indicator light 5 and a full circuit self-test indicator light 3. The undervoltage indicator l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com