Pulsed eddy current detection method and device for eliminating lift-off effect

A pulsed eddy current and lift-off effect technology, applied in the direction of material magnetic variables, can solve problems such as complex calculations and complex devices, and achieve the effects of simple detection devices, improved safety detection, and eliminated lift-off effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

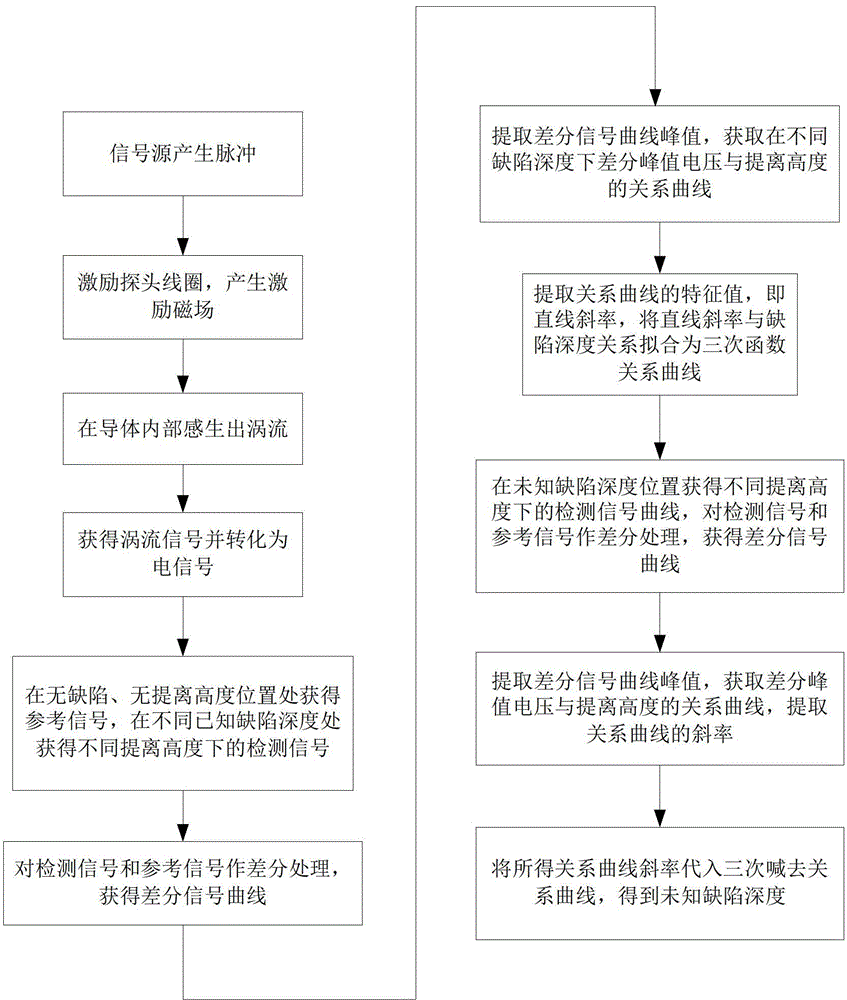

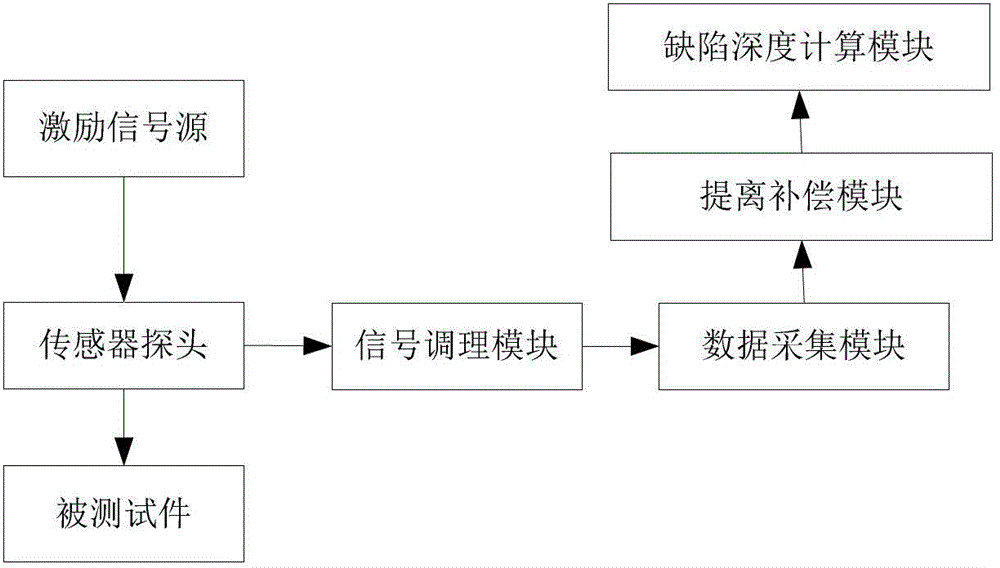

[0052] Such as figure 1 Shown is a flow chart of a pulsed eddy current detection method for eliminating the lift-off effect according to an embodiment of the present invention, and its steps specifically include:

[0053] S1. Obtain the time-domain curves of the detection signal at different lift-off heights for the tested piece at different known defect depth positions and obtain the time-domain curve of the reference signal without lift-off height at the non-defective position of the tested piece, and The time domain curves of the detection signal and the reference signal are subjected to differential processing and feature value extraction processing to obtain the relationship curve between the slope of the differential peak voltage fitting line and the depth of the defect. The specific sub-steps include:

[0054] S11, generating a pulse excitation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com