Constant-pressure inner loop acidification blowing absorption device

An absorption device and internal circulation technology, which is applied in the field of constant pressure internal circulation acidification blowing absorption device, can solve the problems of sulfide and cyanide loss, pressure change is difficult to control, and experimental equipment is complicated, so as to achieve convenient addition and prevent acidity Effect of gas leakage and improvement of absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

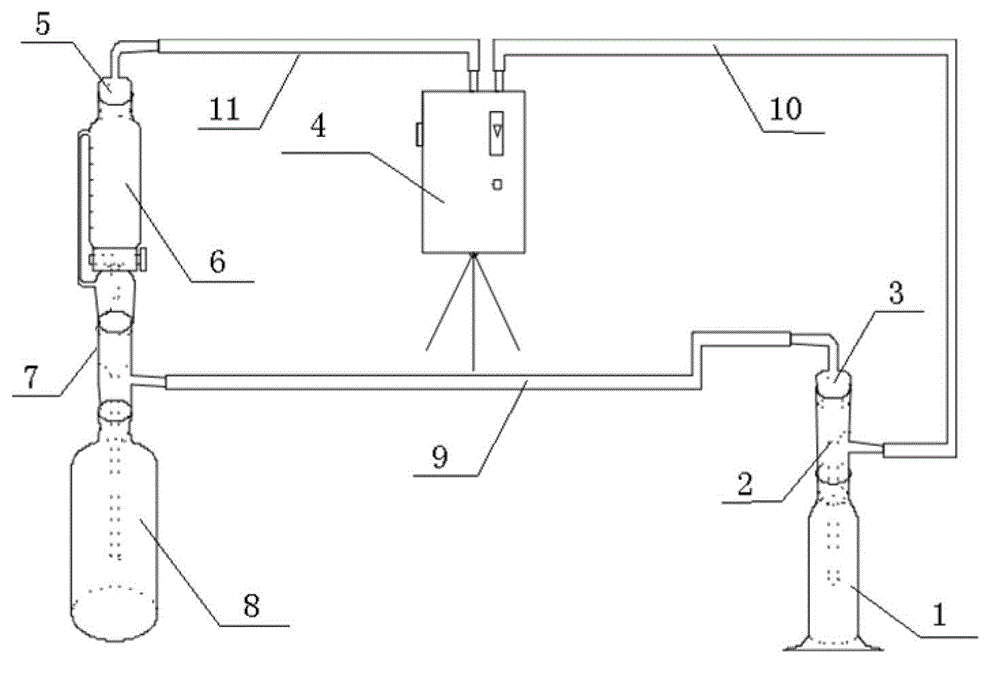

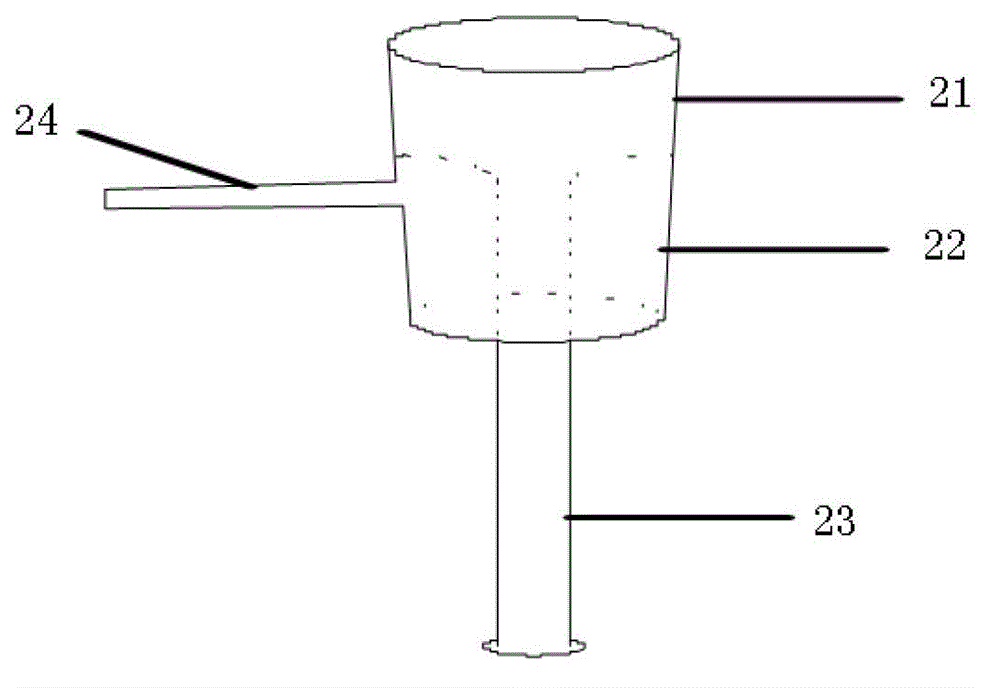

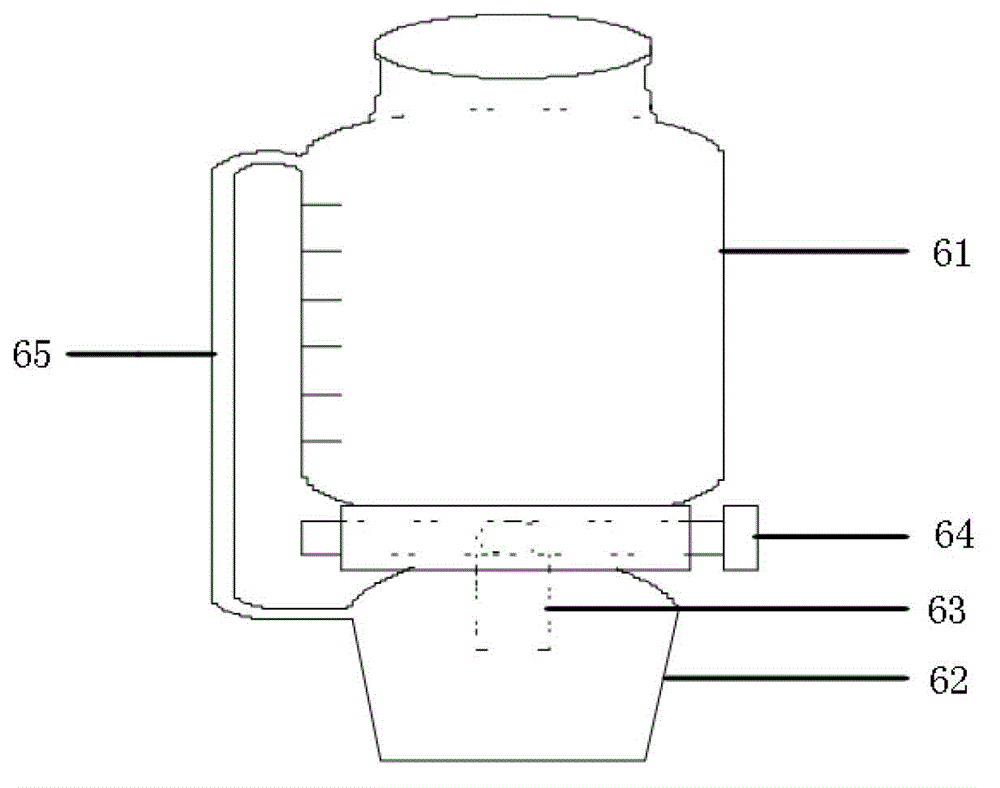

[0024] Embodiment: As shown in the figure, a constant-pressure internal circulation acidification blowing absorption device includes an absorption bottle 1, a first bubbler 2, a first blowing plug 3, a circulation flow meter 4, and a second blowing plug 5 , constant pressure acid adder 6, the second bubbler 7 and reaction bottle 8, the first bubbler 2 includes the upper interface 21 and the lower interface 22 that are arranged up and down, and the bottom of the upper interface 21 of the first bubbler 2 The connected bubble tube 23 and the air outlet tube 24 communicated with the lower interface 22 of the first bubbler 2, the bubble tube 23 of the first bubbler 2 stretches out from the lower interface 22 of the first bubbler 2, the second The structure of the second bubbler 7 is the same as that of the first bubbler 2. The constant pressure acid adder 6 includes an acid bottle 61 and a lower interface 62 arranged up and down. The bottom of the acid bottle 61 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com