Pipeline gas pressure measuring device

A pressure measuring device and gas technology, applied in the direction of measuring device, measuring fluid pressure, simultaneous measurement of multiple hydraulic valves, etc., can solve problems such as inability to measure accurate values, achieve the effect of improving flow state and suppressing severe impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

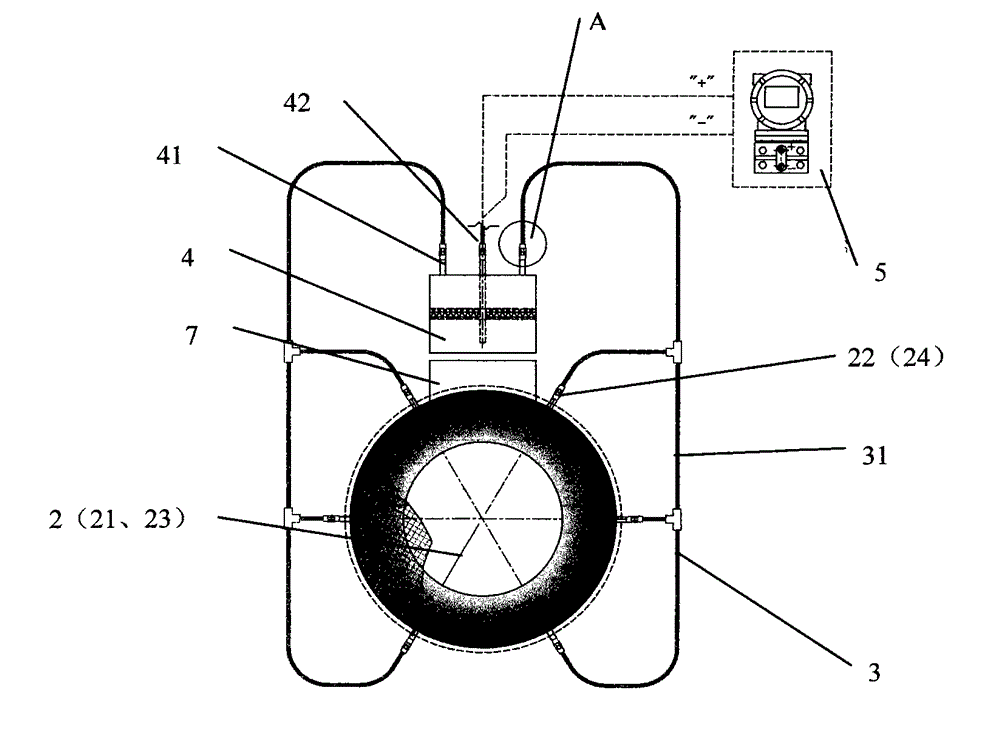

[0059] Such as figure 1 As shown, the pipeline gas pressure measuring device of the present invention is composed of a housing 1, a pressure measuring tube 2, a line pipe 3, a pressure equalizing tank 4 and a differential pressure sensor 5, wherein the housing 1 is a circular pipeline. In actual engineering, The shape of the housing is consistent with the shape of the ventilation duct. In some special cases, the ventilation duct may be square or other polygonal. The shape of the duct does not affect the use of the duct gas pressure measuring device of the present invention. The housing is embedded and fixed on the pipeline. The direction of the arrow in the figure is the flow direction of the gas in the pipeline, the position where the gas enters is the front, and the position where the gas leaves is the back.

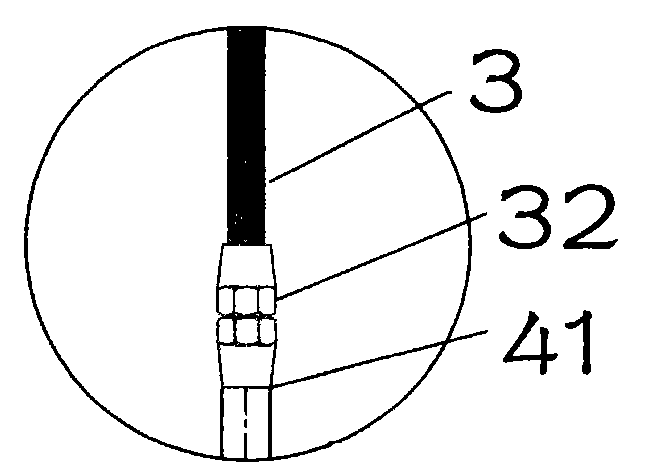

[0060] Three pressure measuring tubes 2 are arranged radially inside the housing 1, and the pipe head 22 (24) of the pressure measuring tube 2 protrudes out of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com