Calibration and non-uniformity correction method for area array infrared camera based on variable integration time

A non-uniformity correction, infrared camera technology, applied in radiation pyrometry, measuring devices, instruments, etc., can solve the problem of not getting rid of blackbody dependence, not considering IRFPA blind element detection and compensation, least squares integration time points, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

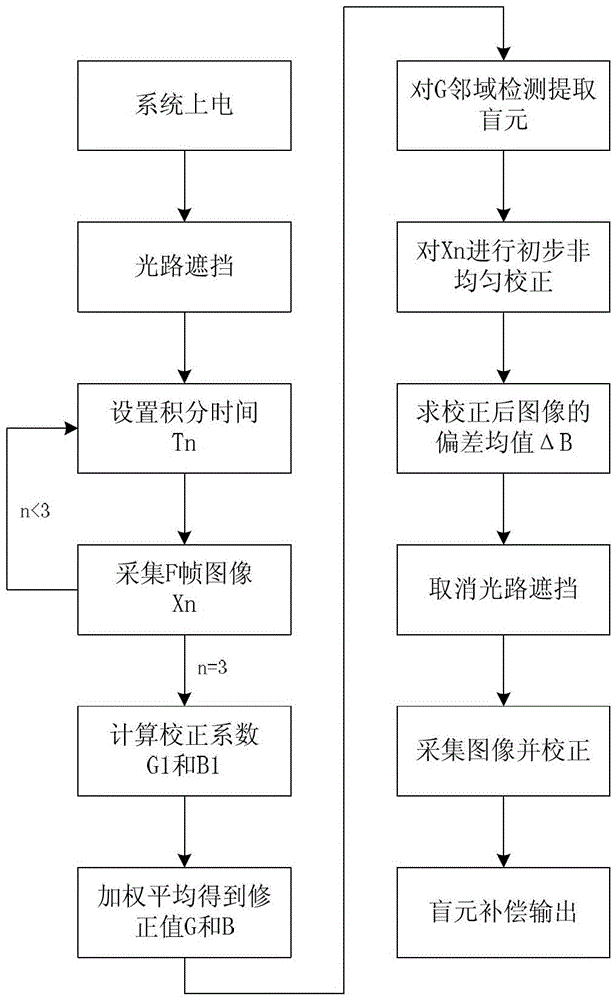

[0037] The present invention is an area array infrared camera non-uniformity correction method based on variable integration time calibration. Under the condition of fixed incident radiation, through FPGA software programming, the integration time of the area array infrared camera is automatically increased at equal intervals, by t 1 increment to t n , and collect a frame of image under the corresponding integration time, set as X 1 (i,j),X 2 (i,j),...X n (i, j), the corresponding integration time is t 1 , t n ,...t n , (i, j) is the pixel coordinates; according to the classic two-point correction coefficient calculation formula, the correction coefficient G is calculated respectively with two adjacent frames of integration time k (i, j) and B k (i, j), k=1, 2, . . . n-1. The final gain correction coefficient G(i, j) is determined by Gk The weighted mean of (i, j) is obtained, and the bias correction coefficient B(i, j) is obtained by B k The mean value of (i, j) is ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com