Door lower bar for energy-saving aluminum alloy glass door

A technology of aluminum alloy and glass, applied in the direction of door leaves, etc., can solve the problems of unsatisfactory performance and low wind pressure resistance of aluminum alloy doors, and achieve the effect of enhanced anti-deformation ability, simple structure and strong strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

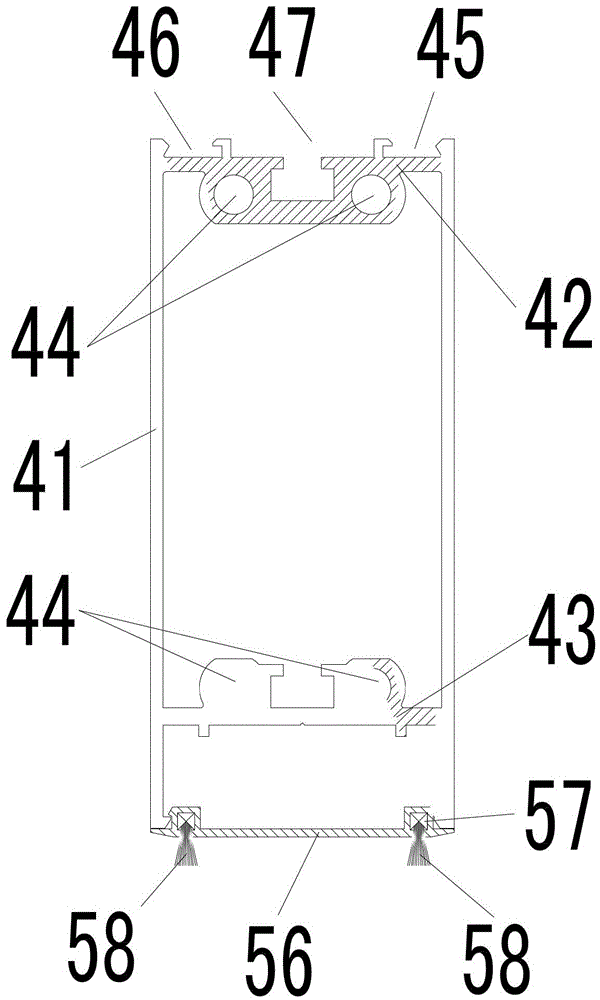

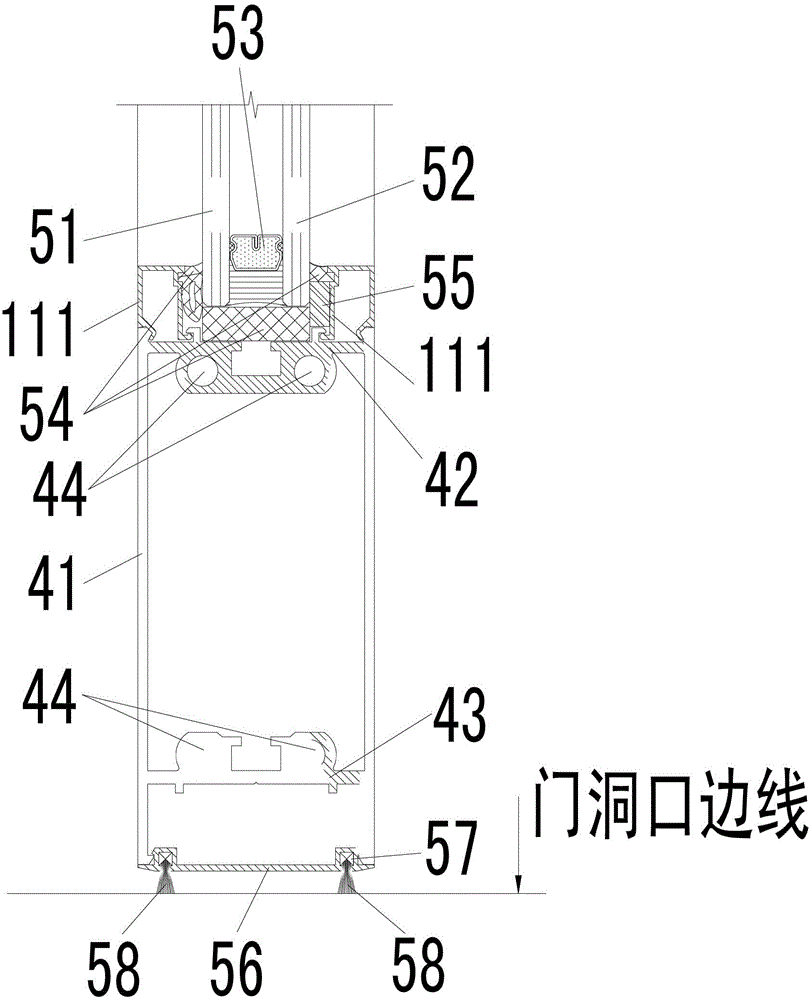

[0016] attached figure 1 It is a door lower rail for an aluminum alloy glass energy-saving door according to the present invention, which includes a door lower rail body 41 and a door rail wrapping 56; the door lower rail body 41 is set to be hollow; the door rail wrapping 56 is arranged under the door The lower end of the horizontal main body 41; the surface of the door horizontal edging 56 is provided with horizontal pores 57; the horizontal pores 57 are multiple, and are arranged on the surface of the door horizontal edging 56 at intervals; each horizontal pore 57 Horizontal wool strips 58 are respectively arranged inside; the upper side end of the lower horizontal body 41 of the door is provided with a first notch 45, a second notch 46, and a third notch 47; the third notch 47 is arranged on the first between the notch 45 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com