Sectional steel tripod and scaffolding system in a cantilevered scaffolding

A scaffolding and cantilever technology, applied in the field of scaffolding, can solve problems such as potential safety hazards, achieve the effect of improving efficiency, meeting the requirements of construction period, and simply transmitting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

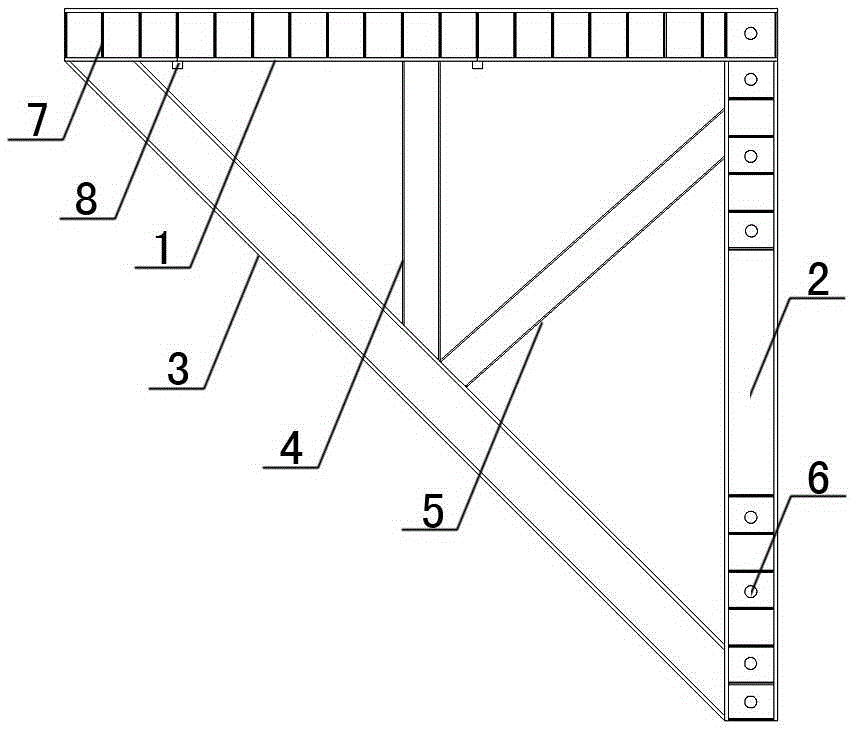

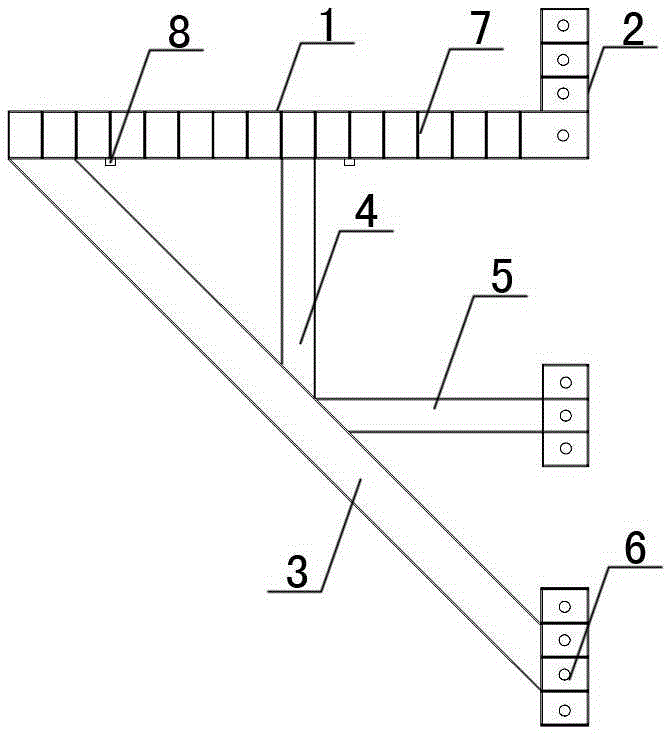

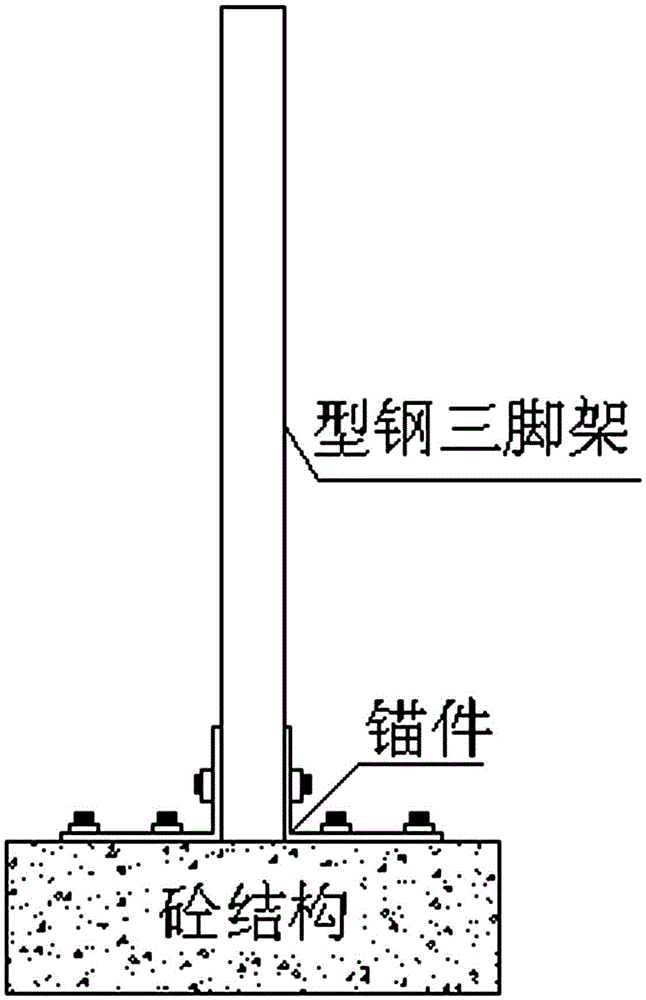

[0021] see Figure 1-2 Shown: a steel tripod in a cantilevered scaffold, including beam 1, vertical brace 2 and diagonal brace 3, the beam, vertical brace and diagonal brace form a triangular structure, and a small vertical brace is arranged between the beam and the diagonal brace 4. There is a small horizontal brace 5 between the vertical brace and the diagonal brace, and there are reserved holes 6 for high-strength bolts on the vertical brace. The anchors connect the vertical brace with the structural column or wall through the reserved holes to realize the installation of the steel tripod , where the beam and vertical brace are 14# I-steel, the small vertical brace and small horizontal brace are 10# I-steel, the beam is provided with stiffening ribs 7, and the limit steel head 8 is provided under the beam;

[0022] Where there are cantilevered beams or decorative eaves but no floor slab outside the structural shear wall or structural column, the vertical braces are continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com