Shallow sea wind electricity facility force absorption pile

A suction pile and wind power technology, applied in the field of marine equipment, can solve the problems of high pile foundation price and difficulty in fixing, and achieve the effect of small pile pulling resistance, high reliability, simple principle and theory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

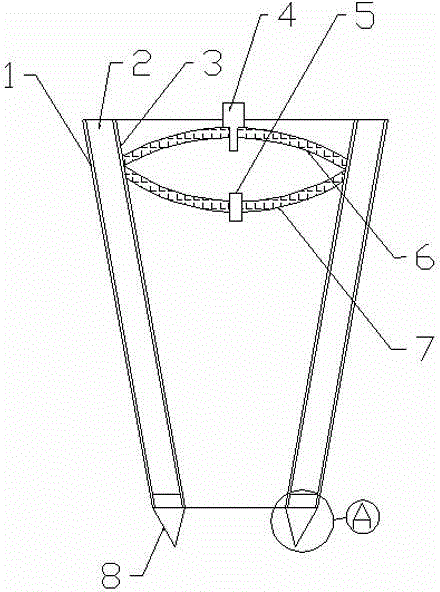

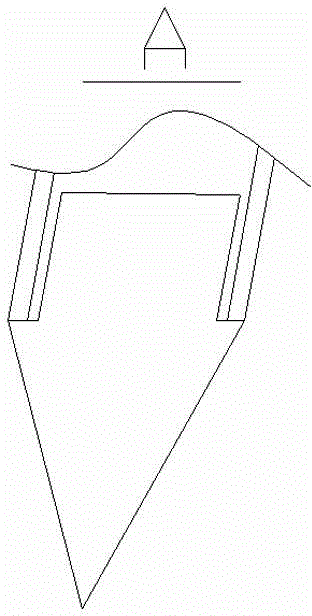

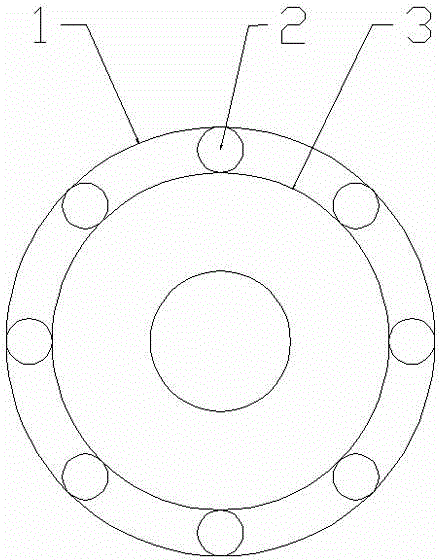

[0018] Suction pile for shallow sea wind power facilities, including outer cylinder 1, grouting pipe 2, inner cylinder 3, vacuum pump 4, one-way valve 5, upper donor 6, lower donor 7 and plug 8, outer cylinder 1 and inner cylinder A grouting pipe 2 is installed between the body 3, and the three are fixed into one body by linear laser welding, and the stress at the weld can be relieved through Hawker; the inner cylinder 3 is welded with an upper donor 6 and a lower donor 7, and the upper donor A vacuum pump 4 is installed on the donor 6 for vacuuming to form a negative pressure, and a check valve 5 is installed on the lower donor 7 to prevent air leakage; a plug 8 is installed at the lower end of the grouting pipe 2 .

[0019] Eight grouting pipes 2 are evenly distributed between the outer cylinder 1 and the inner cylinder 3; the plug 8 is conical to acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com