Amplitude variation station crane with clutch

A technology with a clutch and a work station, applied in the field of spreaders, can solve the problems of affecting the layout of the work station, occupying a large space, difficult to operate, etc., and achieve the effect of simple and beautiful structure, small space, and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

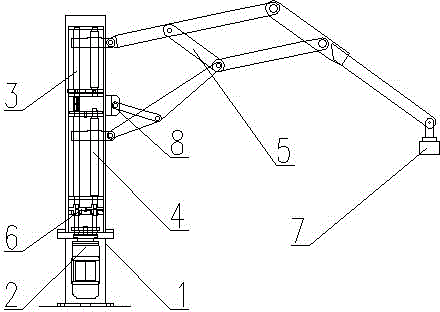

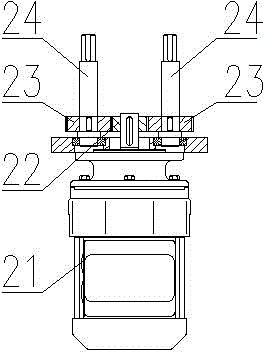

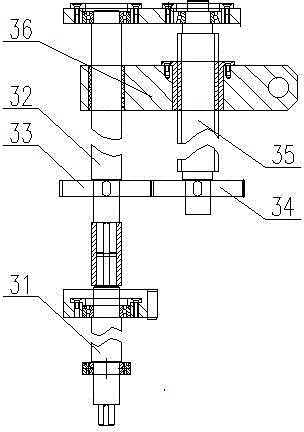

[0019] like figure 1 — Figure 5 As shown, the luffing station crane with clutch includes a fixed bracket 1, a driving device 2, a lifting device 3, a translation device 4 and a six-bar linkage mechanism 5, and the driving device 2, lifting device 3 and translation device 4 are fixed on a fixed Inside the bracket 1, the driving device 2 is fixed on the bottom of the fixed bracket 1, the lifting device 3 and the translation device 4 are arranged in parallel above the driving device 2 and are respectively connected to the driving device 2 through the electromagnetic clutch 6, and the six-bar linkage mechanism 5 is connected to the lifting device 2. The device 3, the fixed bracket 1, and the translation device 4 are hingedly connected. The lifting device 3 controls the six-bar linkage mechanism 5 to move up and down, and the translation device 4 controls the horizontal movement of the six-bar linkage mechanism 5.

[0020] The six-bar linkage mechanism 5 is made up of six connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com