Automatic heat dissipation type free-flow electrophoresis separation chamber device

An electrophoretic separation and heat dissipation technology, which is applied to the separation of dispersed particles, measurement devices, separation methods, etc., can solve the problems of inconvenience of polyacrylamide gel membrane, difficulty in ensuring the sealing performance of the separation chamber, and inconvenient assembly of the separation chamber, etc. To achieve the effect of compact separation chamber device, improved electrical conductivity and good water leakage prevention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

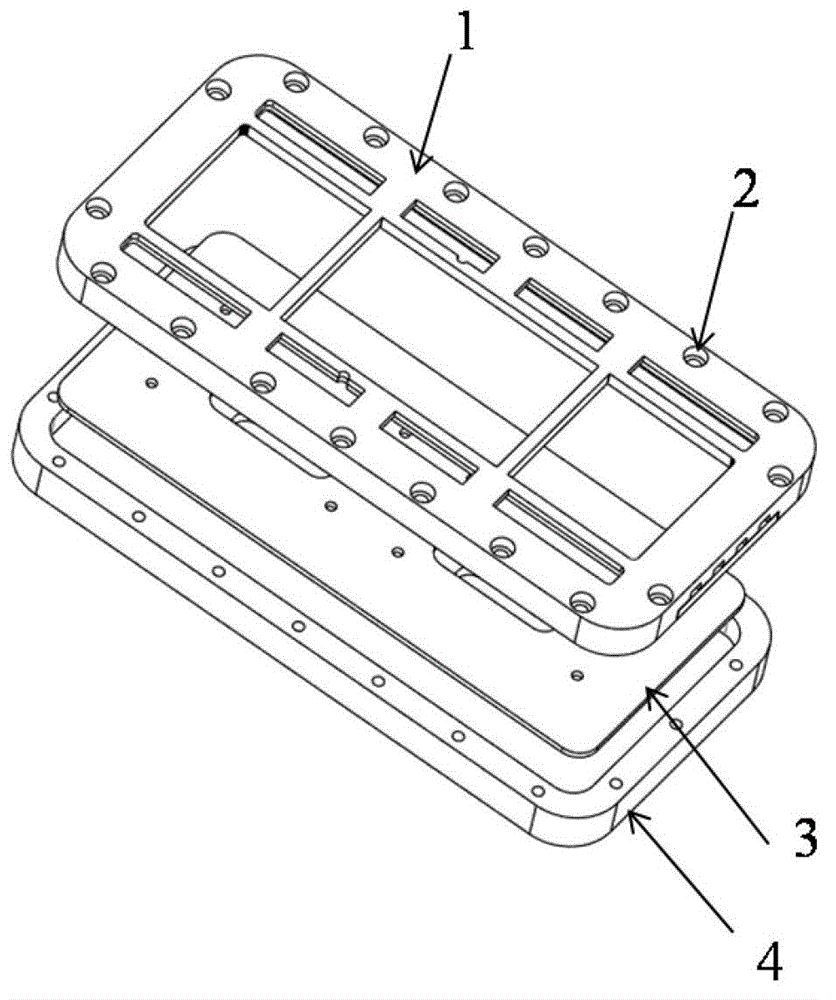

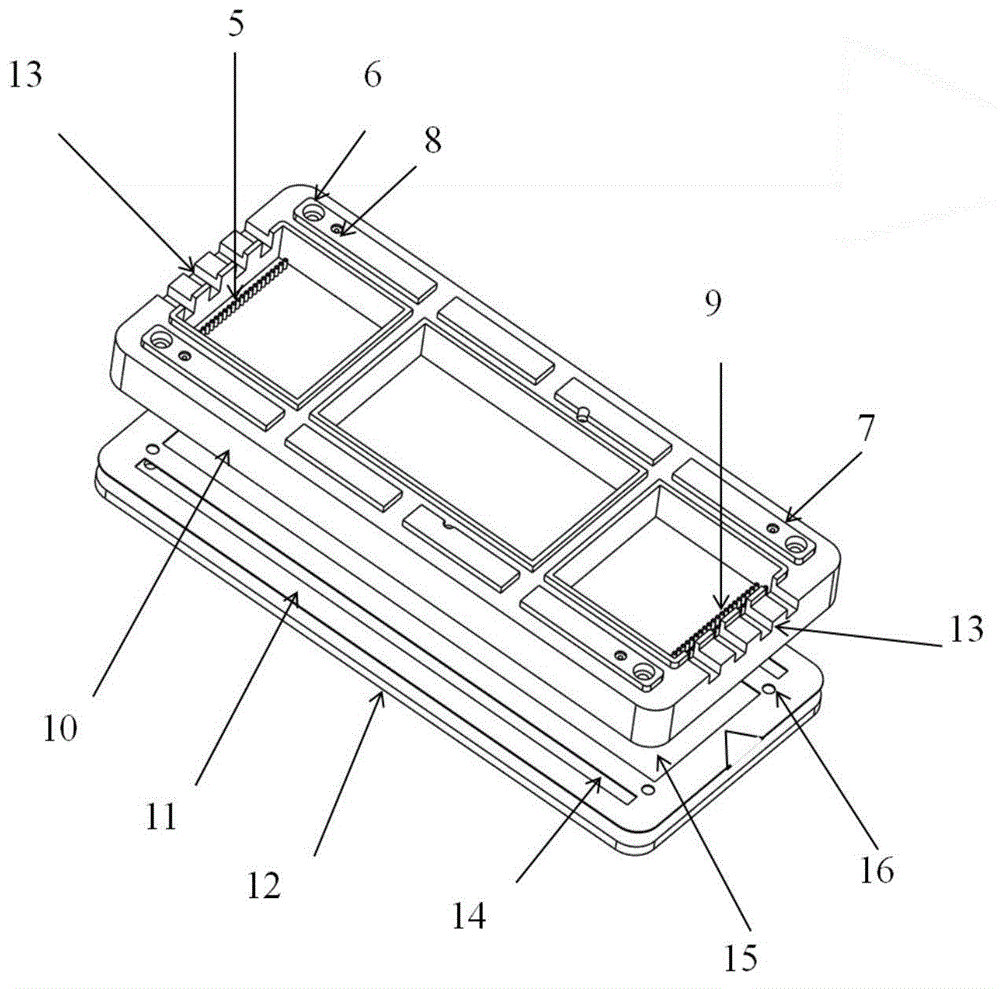

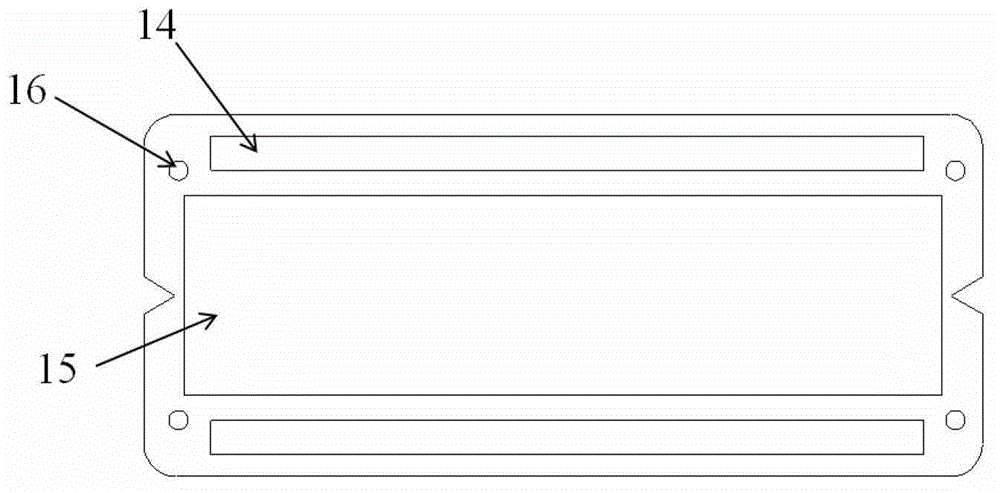

[0029] Such as Figure 1 to Figure 10 As shown, the present invention includes a semiconductor refrigeration sheet 26, an air-cooled radiator 27, a thermally conductive silica gel 28, a temperature controller 29, a DC power supply 30, a temperature sensor 31, a fastening structure upper part 1, an organic glass plate 10, and an ion membrane 11 , ceramic plate 12, rubber pad 3, fastening structure lower part 4, inlet guide plate 18 and outlet guide plate 17, semiconductor cooling plate 26, air-cooled radiator 27, thermal silica gel 28, temperature controller 29, DC The automatic heat dissipation system composed of power supply 30 and temperature sensor 31 is evenly coated with thermal conductive silica gel 28 between the semiconductor refrigeration sheet 26 and the top copper sheet of the air-cooled radiator 27, and the upper part 1 of the fastening structure, the organic glass plate 10, and the ion membrane 11. The ceramic plate 12, the rubber pad 3, and the lower part 4 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com