Self-locking screw

A threaded and self-locking technology, used in threaded fasteners, screws, bolts, etc., can solve problems such as mechanical damage and weakening of the tightening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] figure 1 A three-dimensional view of a screw 10 with a head 12 and a shank 14 with an external thread 16 according to the invention is shown. According to the invention, protrusions 20 are provided on the tooth side of the thread that is stressed when the thread is tightened, this tooth side is also the tooth side 18 of the external thread 16 in this embodiment, and this tooth side is at the figure 1 The center is directed upwards, while the protrusion 20 extends over the limited bending portion of the respective thread turn into the thread turn. In the present embodiment, the protrusions 20 are each spaced approximately 120° apart, that is to say, one thread has three protrusions 20 . In total the protrusions cover approximately 1 / 3 of the full turn of the thread. The protrusions are designed to taper sharply in the direction of rotation and have a rounded tip, so that they arch with a circular arc-shaped cross section.

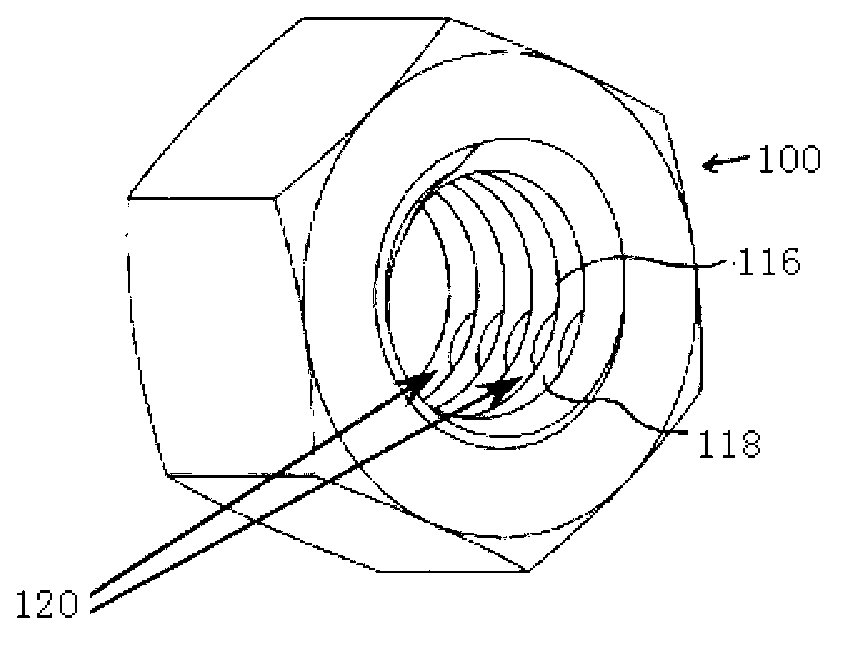

[0016] figure 2 A nut 100 according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com