Copolymer fibers and processes for making same

A copolymer and copolymerization technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, wet spinning method, etc., can solve the problems of low investment economy, expensive known methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

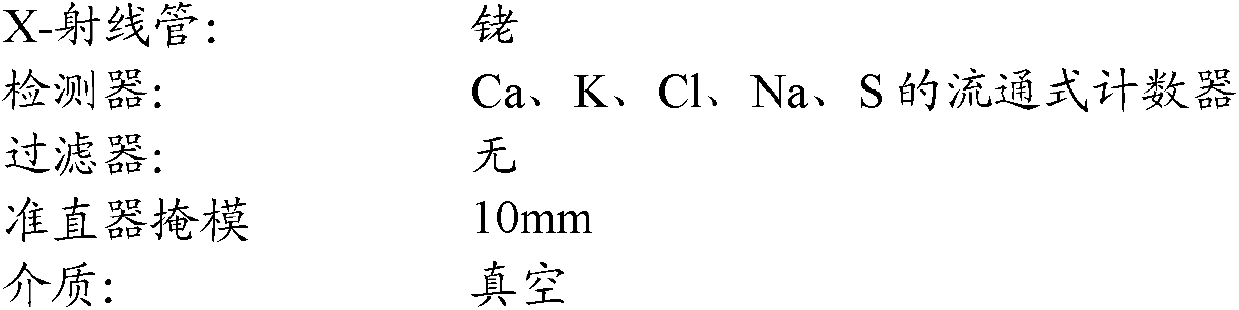

Image

Examples

example 1

[0078] One unwashed yarn sample on the tube was placed in a continuously replenished overflow deionized water bath for 12 hours at -20°C. The yarn sample on the tube was then placed in contact with 1 liter of 2.0% by weight sodium hydroxide in water (0.5 moles NaOH / liter) for 1 hour. The yarn samples were then placed in a continuously replenished overflow deionized water bath for 1 hour at ~20°C. Excess liquid was then removed from the yarn and dried in a tube oven at 160°C. The yarn was then heat treated under nitrogen in a first oven at 300°C and 4.5 cN / dtex and then in a second oven at 450°C and 0.15 cN / dtex. Data on the approximate amounts of cations and their calculated concentrations are in Table 1. The molar ratio of effective polymer cation to sulfur content is about 1, and the hydrolytic strength is expected to remain at about 70%. In the tables, weight-percent, parts-per-million, and moles-per-kilogram are of elements in the yarn.

example 2

[0085] Example 1 was repeated, however the initial water wash was reduced from 12 hours to 8 hours. The molar ratio of effective polymer cation to sulfur content was about 0.5, and the hydrolytic strength was expected to remain about 55%, less than Example 1, reflecting the effect of the first water wash.

example 3

[0087] Example 1 was repeated, however the initial water wash was increased from 12 hours to 16 hours. The molar ratio of effective polymer cation to sulfur content was about 2, and the hydrolytic strength was expected to remain about 80%, greater than Example 1, reflecting the effect of the first water wash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com