Reset mechanism of dual-breakpoint breaker

A technology of reset mechanism and circuit breaker, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of difficulty in realization, increase in re-buckling force, increase in electric operating force or manual operating force, etc., so as to improve breaking capacity and electrical life, The effect of accelerating breaking speed and accelerating breaking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

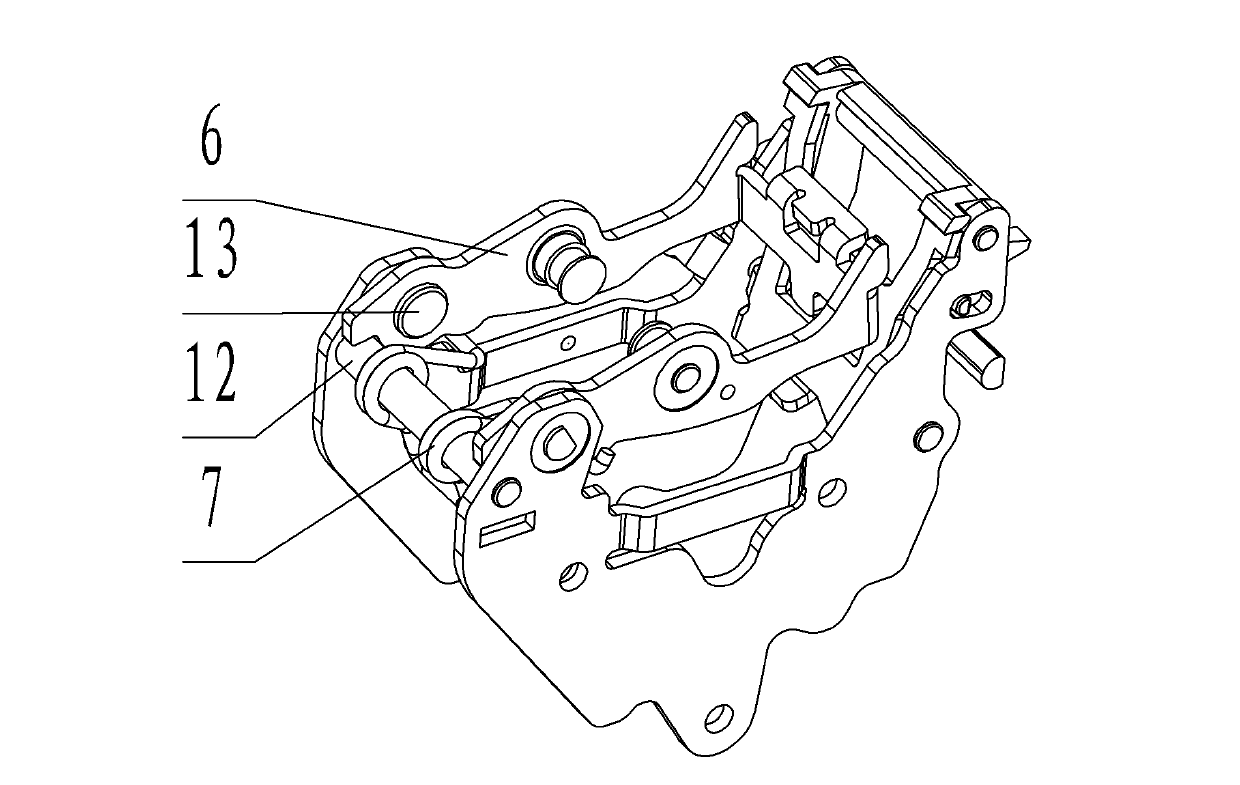

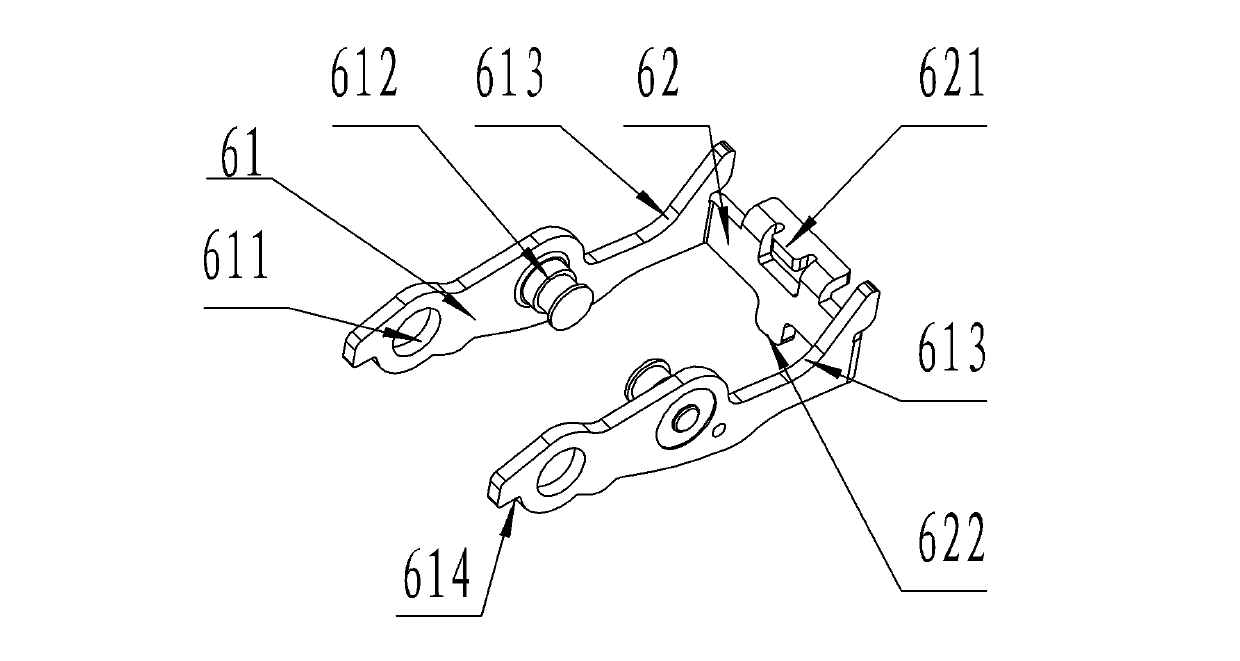

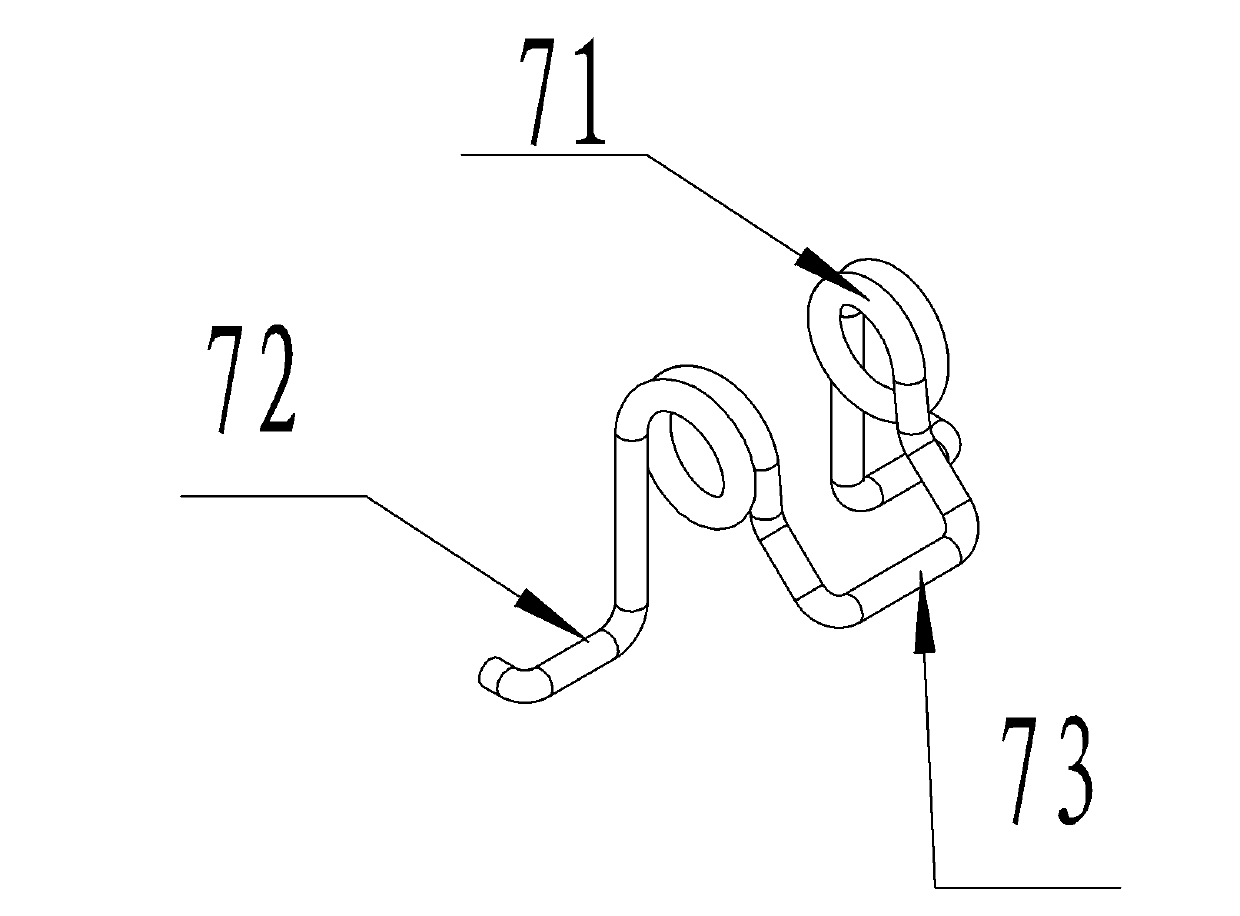

[0027] Such as figure 1 , Figure 4 As shown, the present invention is a double-breakpoint circuit breaker reset mechanism, which includes a U-shaped jumper 6, the arms on both sides of the jumper 6 are rotatably installed on the inner sides of the two side plates 5, the jumper 6 and the circuit breaker Cooperate with the transmission mechanism and the tripping mechanism, and also include a return spring 7 running through a positioning shaft 12, the positioning shaft 12 is fixed between the two side plates 5, and the return spring 7 is connected by two torsion springs 71, as image 3 As shown, the connecting portion 73 of the two torsion springs is limited on a fixed surface as the fixed end of the return spring, as Figure 4 The connecting parts 73 of the two torsion springs shown are fixed on the single box body 8 of the circuit breaker, the two legs 72 of the return spring 7 are connected with the two side arms of the jumper 6, and the two legs 72 of the return spring are ...

Embodiment 2

[0038] The structure of this embodiment is basically the same as that of Embodiment 1, except for the specific structure of the return spring in this embodiment and the matching structure of the return spring and the jumper. Such as Figure 8 , Figure 9 As shown, the return spring 7 is formed by connecting two torsion springs 71. Compared with the return spring in the first embodiment, the two legs 72 of the return spring are linear, and the rest of the structure is the same as the first embodiment. Correspondingly, the specific structure of the jumper 6 is also modified accordingly. The inner side of the arms on both sides of the jumper 6 is provided with a protruding arm 615, and the end of the protruding arm 615 is bent downward to form a bending portion 616. The leg portion 72 is clamped inside the bending portion (other structures are the same as those described in Embodiment 1). The two leg parts 72 of the return spring are limited inside the two bent parts of the jum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com