Material loading manipulator

A technology of manipulators and grippers, applied in the field of manipulators, can solve the problems of lack, lack of operability and practicality of students' design content, and lack of perceptual understanding of manipulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

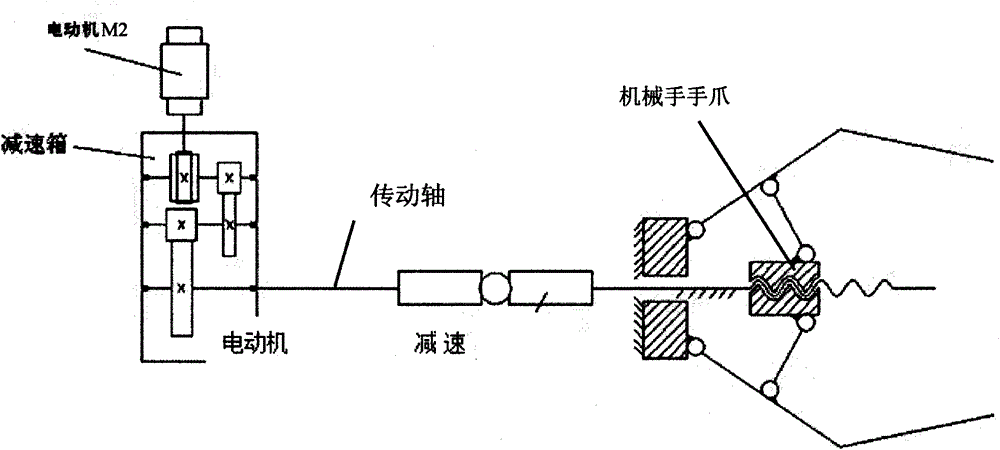

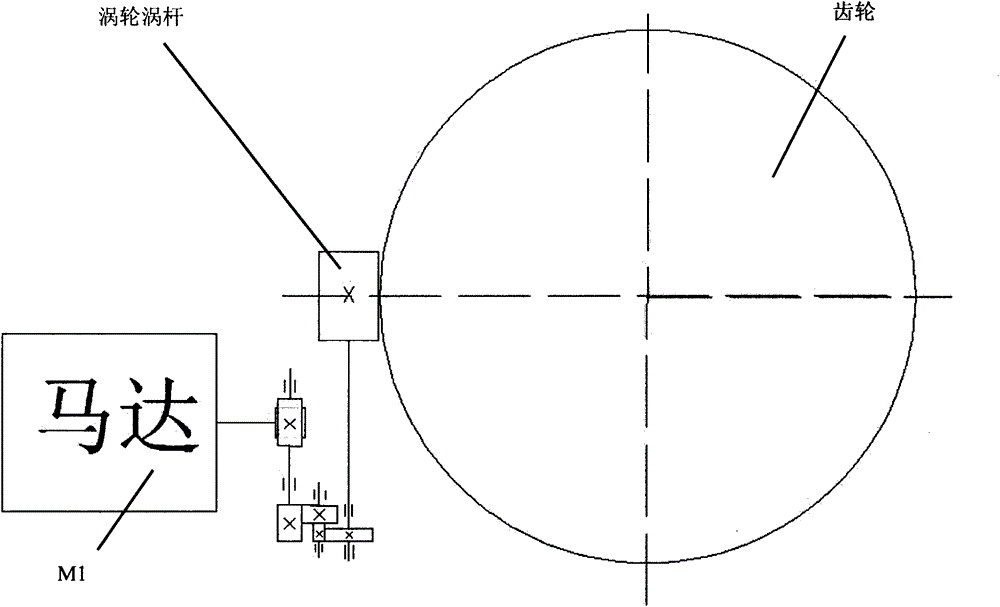

[0008] A feeding manipulator, consisting of a motor M1, an electric motor M2, a gearbox, a manipulator gripper, a worm gear, and a drive shaft. The dovetail groove insertion method of the fischer creative combination model installs the motor M1 on the platform plate, and then assembles it on the The deceleration device, the worm gear transmission device, and then connect the transmission shaft to drive the motor M2 for opening and closing the gripper, the deceleration device, and the mechanical gripper. After connecting the motor M1 and the motor M2, the single motor can be driven in the vertical direction. The gripping and lowering action of the loading manipulator with degrees of freedom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com