Method for identifying ultrasonic guided wave of oblique crack pipeline through utilizing improved Duffing chaotic system

An ultrasonic guided wave and chaotic system technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of manpower, material waste, lack of scientific maintenance, and high risk of missed inspection, so as to reduce economic losses and reduce maintenance costs. , the effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

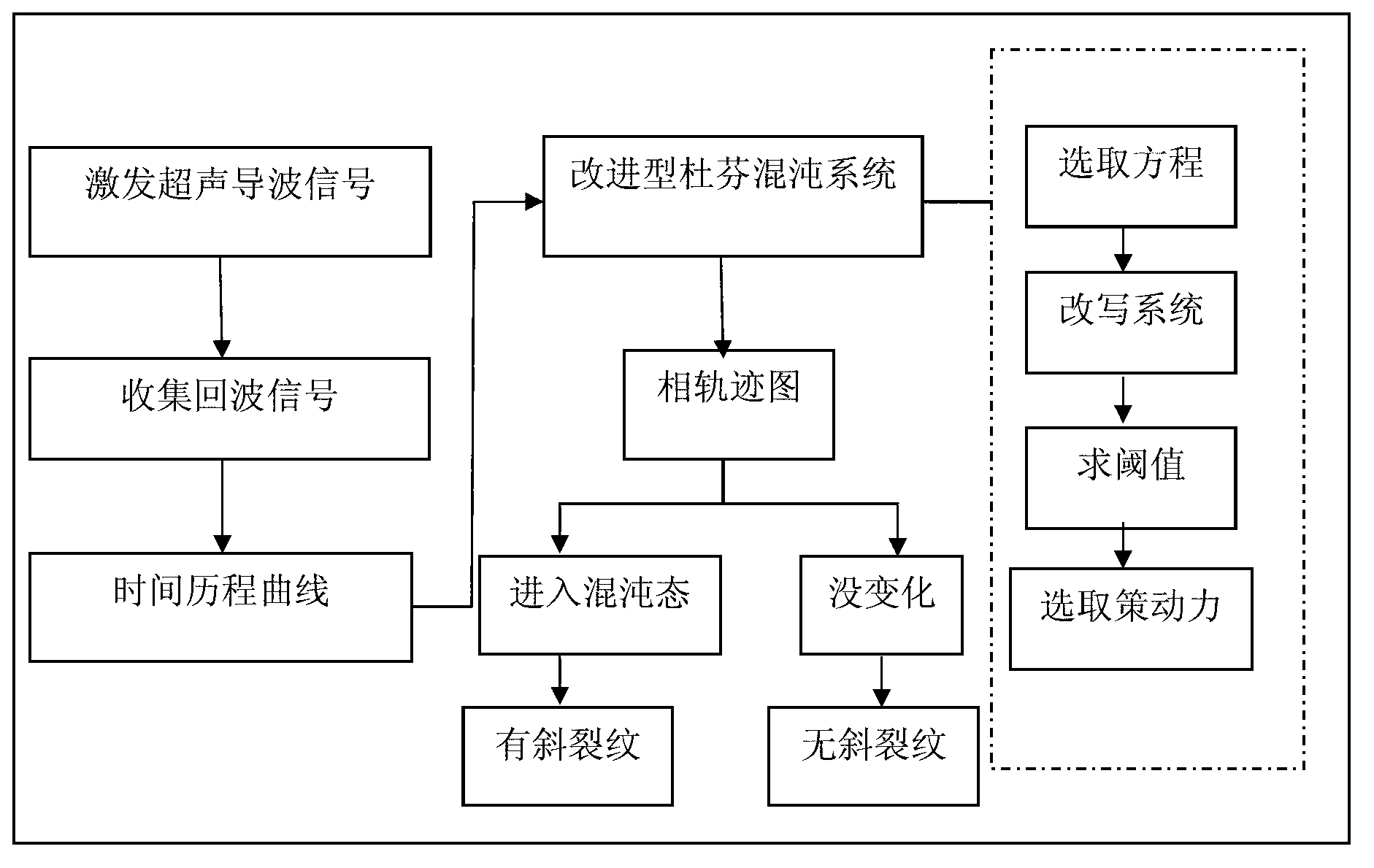

[0042] Such as figure 1 As shown, this embodiment takes a specific pipeline as an example to identify oblique crack defects in the pipeline, as follows:

[0043] 1) Excite the ultrasonic guided wave signal on one side of the specific pipeline, so that the ultrasonic guided wave traverses all positions of the pipeline. The experimental process is as follows:

[0044] a) use three-dimensional drawing software to establish the geometric model of the pipeline, wherein the diameter of the pipeline model is 40mm, and the length is 4m, such as figure 2 shown;

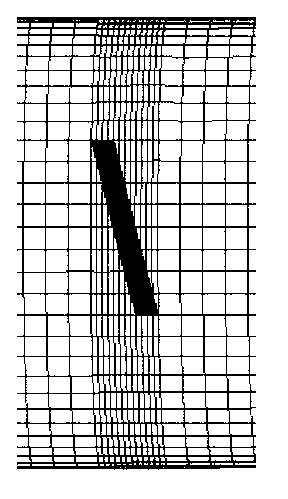

[0045] b) Divide 4 oblique crack defect units at 2m from the central position of the pipeline model, where the thickness of each unit is 1mm, the length is 16mm, and the angles are 15°, 30°, 45° and 90° respectively, as Figures 3a-3d shown;

[0046] c) Define the material and parameters of the pipeline model, where the material is steel and the density is ρ=7.85×10 3 kg / m 3 , elastic modulus E=200GPa, Poisson's ratio μ=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com