Making method of standard samples for verifying heat injury Barkhausen detection sensitivity

A technology of detection sensitivity and production method, applied in the field of non-destructive testing, can solve the problems of no sensitivity calibration test block, difficulty in burning, inability to calibrate equipment, etc., and achieve the effects of easy control of the production process, simple operation, and simple production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] According to the production method of the standard burn sample, the 300M steel thermal damage Barkhausen detection sensitivity calibration standard sample was prepared, and then the degree and nature of the 300M steel thermal damage were determined through acid etching testing.

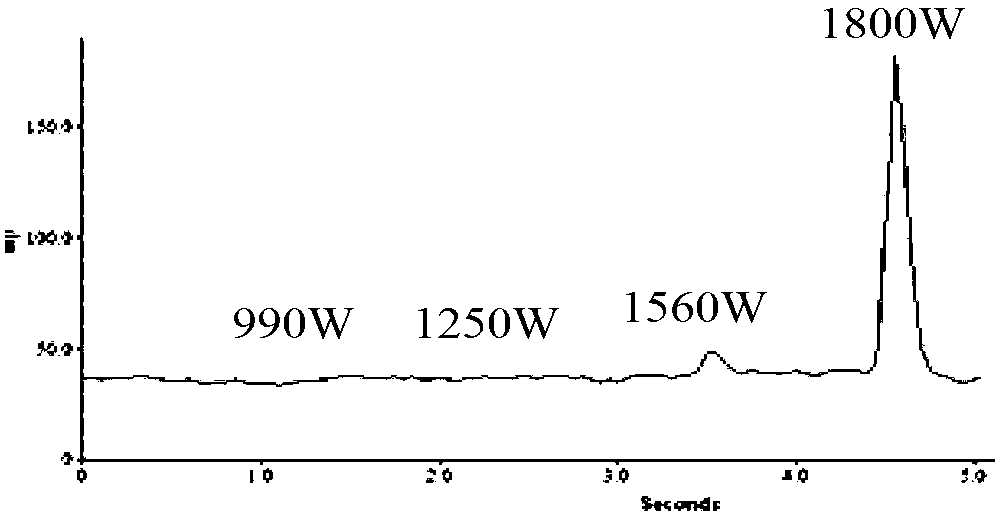

[0031] Select a rectangular block with a size of 250mm×40mm×15mm. After manual polishing, sand blowing is performed to make the surface have a certain light-absorbing function and the surface state is uniform. Using TRUMPF 3000W laser welding equipment, in order to obtain a spot with a diameter of 8mm, it is necessary to adjust the defocus amount to 200mm, gradually increase the laser power from 0 until burn marks appear on the surface, record the power value at this time as 920W, continue to increase the power until heavy Melting phenomenon, record the power value at this time as 2700W. In addition, select a piece of the same sample to make burn spots on it. The increase of burn spots every ti...

Embodiment 2

[0033] The A-100 steel thermal damage Barkhausen detection sensitivity calibration standard sample was prepared according to the standard burn sample production method, and then the degree and nature of the A-100 steel thermal damage were determined through acid etching testing.

[0034] Select a rectangular block with a size of 150mm x 40mm x 13mm. After manual polishing, sand blasting is performed to make the surface have a certain light-absorbing function and the surface state is uniform. Using TRUMPF 3000W laser welding equipment, in order to obtain a spot with a diameter of 8mm, it is necessary to adjust the defocus amount to 200mm, gradually increase the laser power from 0 until burn marks appear on the surface, record the power value at this time as 990W, continue to increase the power until heavy Melting phenomenon, record the power value at this time as 2700W. In addition, select a piece of the same sample to make burn spots on it, and the increase of burn spots every t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com