Sealed integrated smoke collection test device

A test device and an integrated technology, which is applied in the field of integrated flue gas collection and test devices, can solve problems such as the adverse effects of flue gas composition testing and temperature testing, achieve good sealing performance, improve work efficiency, and save disassembly and installation work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

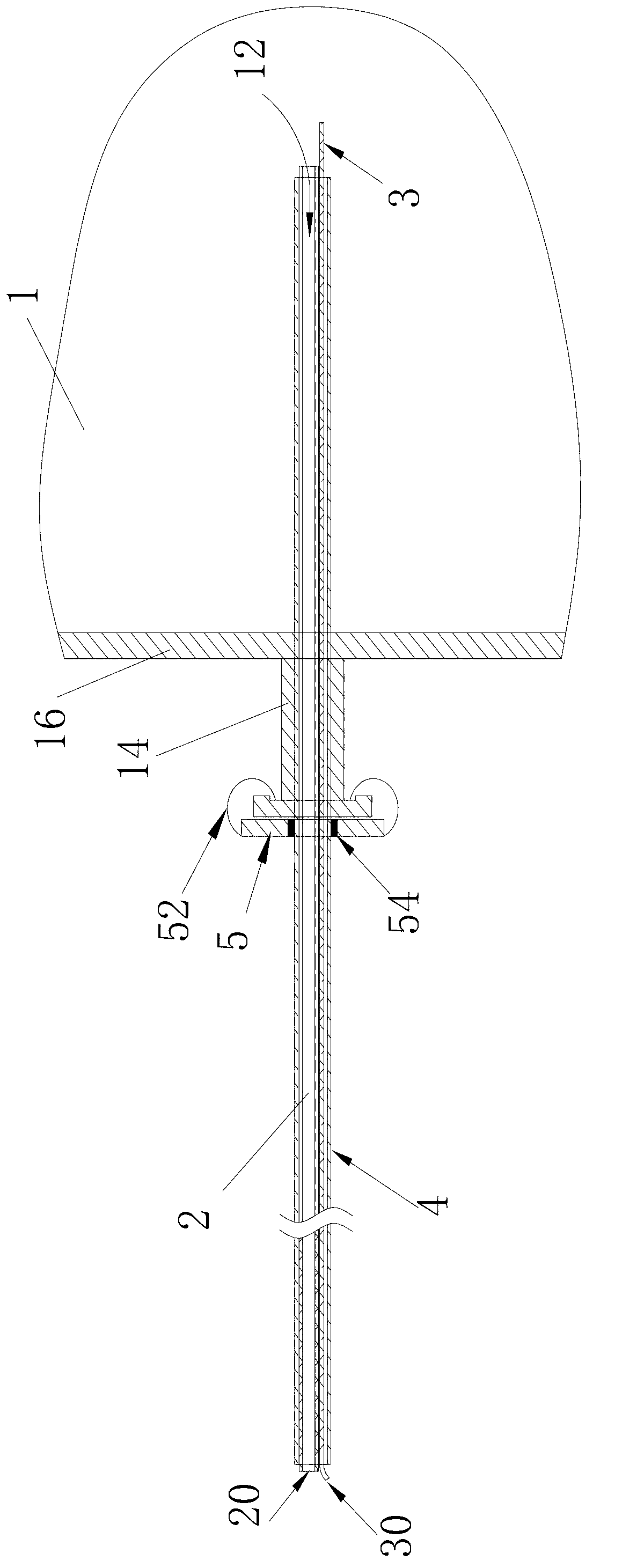

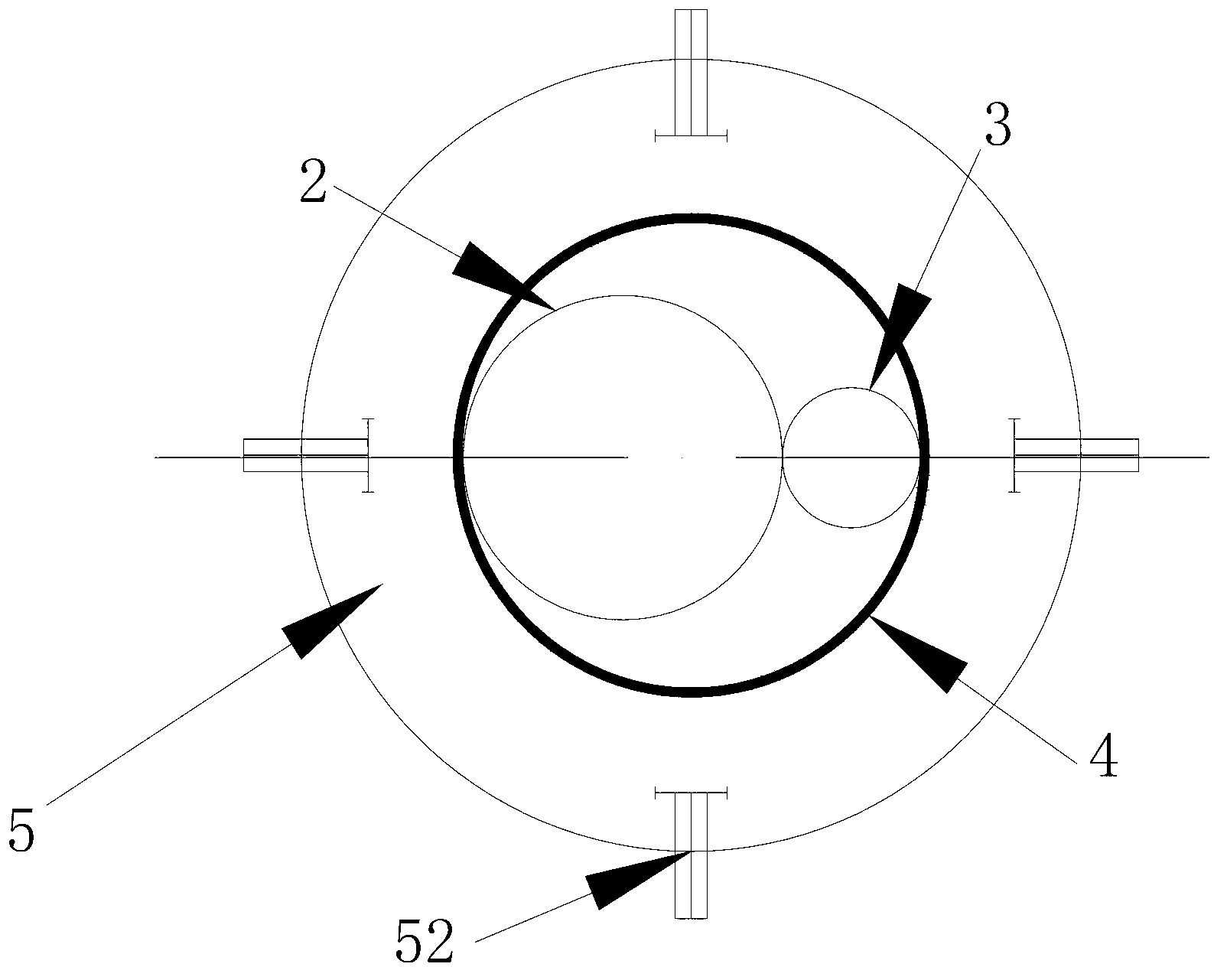

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0034] Such as figure 2 As shown, the present invention proposes a sealed integrated smoke collection and testing device, and the sealed integrated smoke collection and testing device includes:

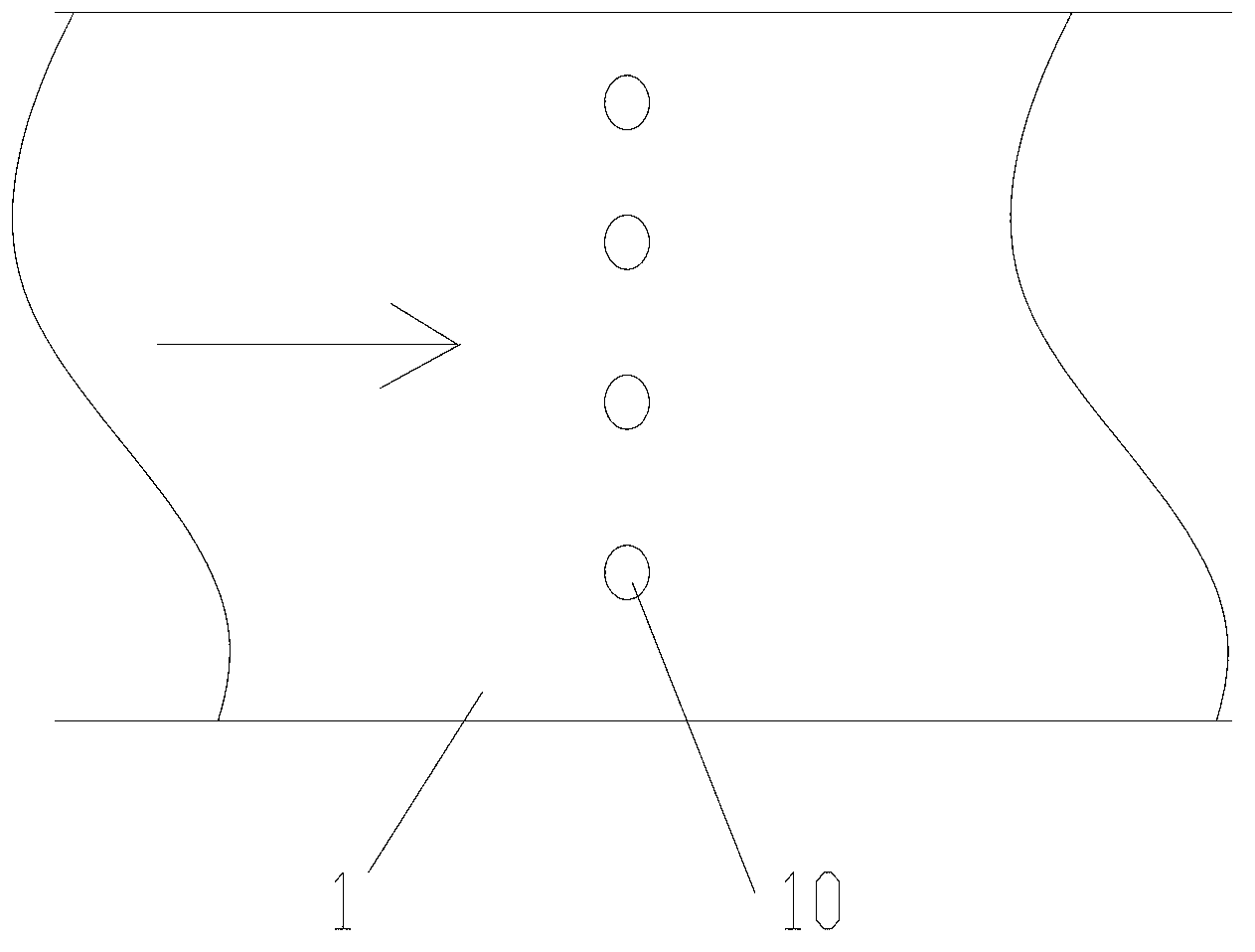

[0035] The sampling hole base 14 is arranged at the sampling hole of the flue 1 to be tested, such as Figure 6 , the sampling hole base 14 has a through hole 146 communicated with the flue to be tested, such as figure 1 , a plurality of sampling holes 10 are provided on the outer wall of the flue 1 to sample and measure different positions of the flue 1, for example, a plurality of sampling holes 10 are provided on the same section of the outer wall of the flue 1, figure 1 The direction of the arrow in indicates the flow direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com