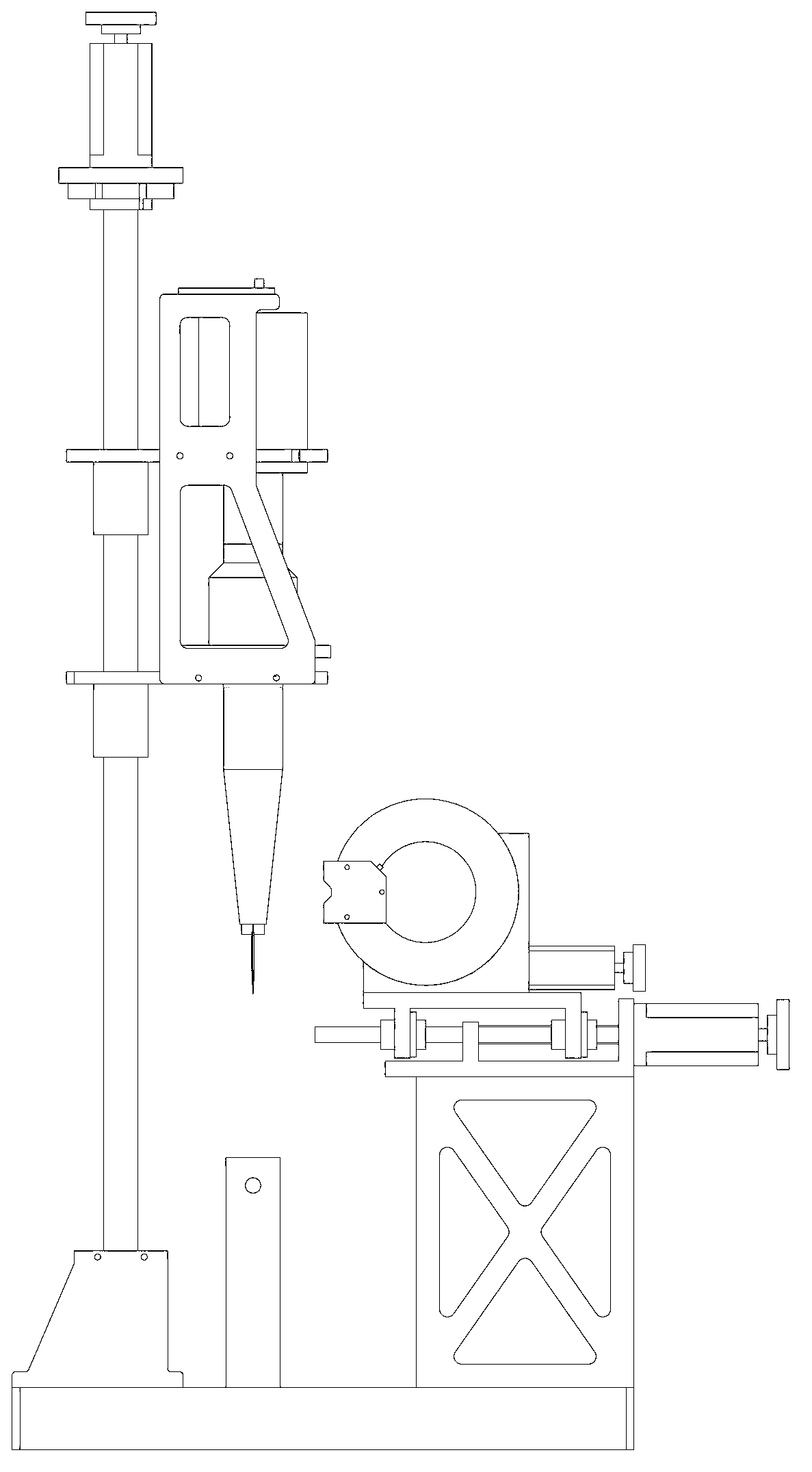

Overall performance testing rack of numerical control ultrasonic cutting sound main shaft

A technology of comprehensive performance testing and ultrasonic cutting, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. Ultrasonic spindle with load comprehensive test and other issues, to facilitate comprehensive and follow-up analysis, improve performance test effect and efficiency, and shorten the research and development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The following is an example of point-by-point CNC testing of the ultrasonic spindle section profile with a high-precision non-contact laser displacement probe to describe the action process:

[0046] First, the clamping of the ultrasonic cutting sound main shaft 24 and the test probe 20, the sound main shaft lower pressure plate 21 is enclosed within its flange ring from the upper end of the ultrasonic cutting sound main shaft 24, so that the stepped hole on the sound main shaft lower pressure plate 21 is aligned with the main shaft. The flange ring cooperates, then the main shaft is put into the stepped hole of the lower fixed plate 7 and the stepped hole is matched with the flange ring. Connect and pre-tighten the lower pressure plate 21 of the acoustic main shaft with the lower fixing plate 7 of the acoustic main shaft with bolts. Then the pressure plate 23 on the sound main shaft is fastened on the fixed plate 5 on the sound main shaft with bolts, and then the bolts...

Embodiment 2

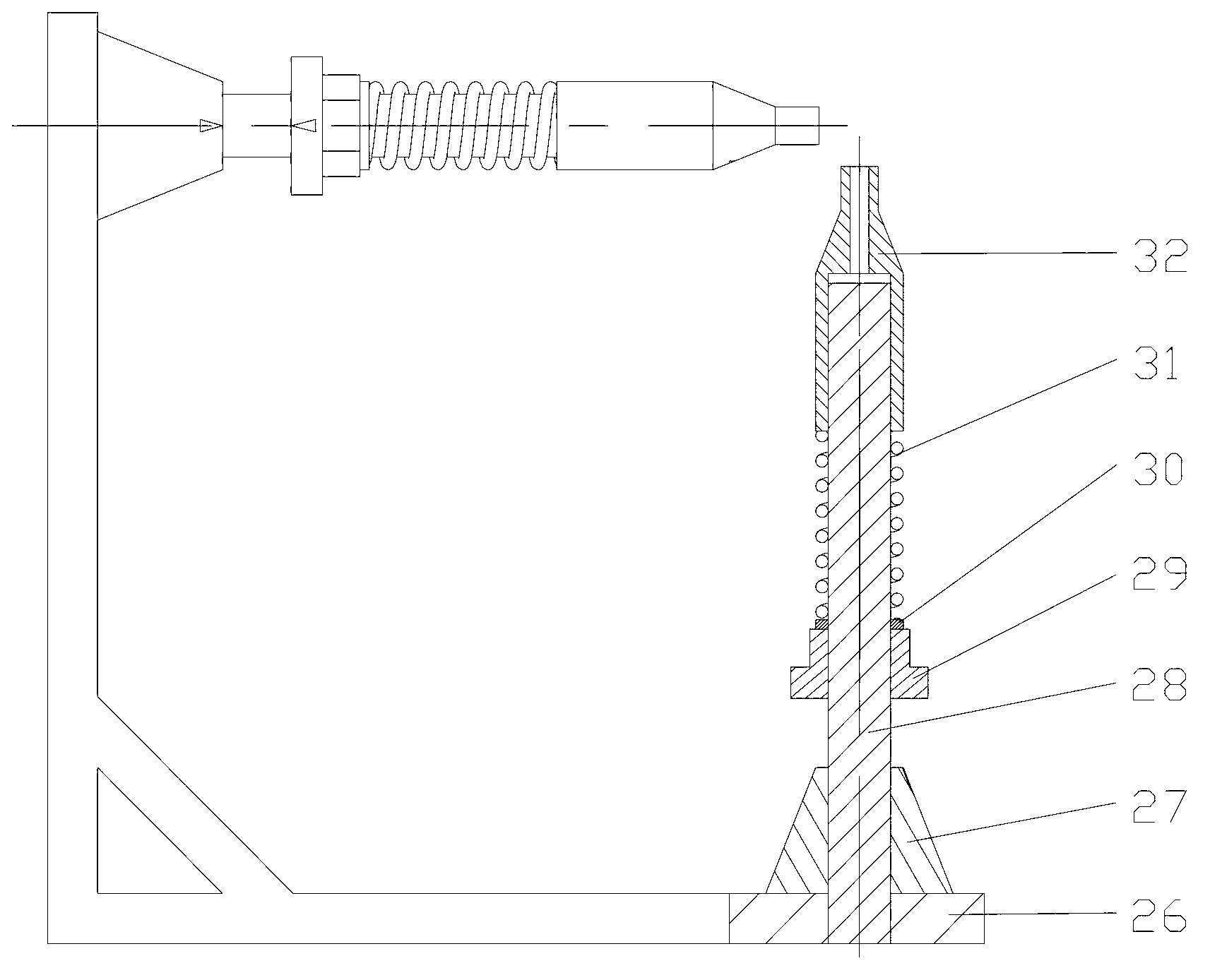

[0050] The following takes the measurement of the impedance characteristics of the ultrasonic cutting spindle under different loads as an example to describe the action process:

[0051]Since the gantry can complete all measurements in one clamping, the measurement process is mainly described. The installation process of the ultrasonic cutting sound spindle 24 is the same as that in Embodiment 1, so it is assumed here that the ultrasonic cutting sound spindle 24 has been installed. . First, the vertical ball screw 4 is driven to rotate by controlling the vertical servo motor 2 or the vertical motor handwheel 1, and then the ball screw pair drives the fixture and the test cutting sound main shaft 24 to move downward along the vertical linear guide rail 9 to make the ultrasonic cutting tool 8 The tip and the two axial and radial force rods 32 of the simulated load system are just in contact with each other, and then the positive and negative electrodes of the main shaft drawn ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com