LED (light emitting diode) lighting lamp of locomotive or bullet train with reflectors

A technology of LED lighting and railway locomotives, applied in the field of outdoor lighting, can solve the problems of short life and high energy consumption, and achieve the effects of enhanced brightness, low energy consumption, and slowing down damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

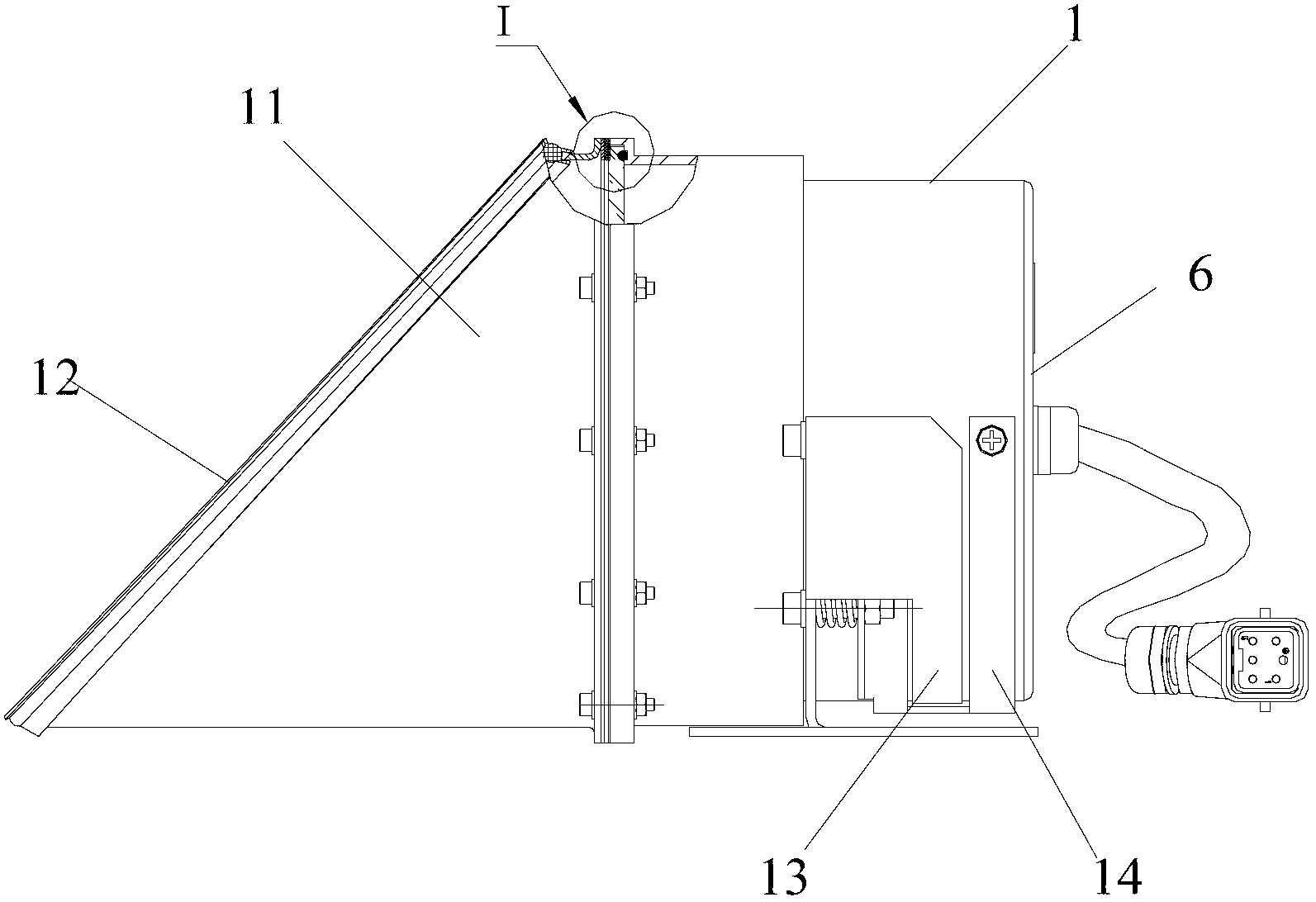

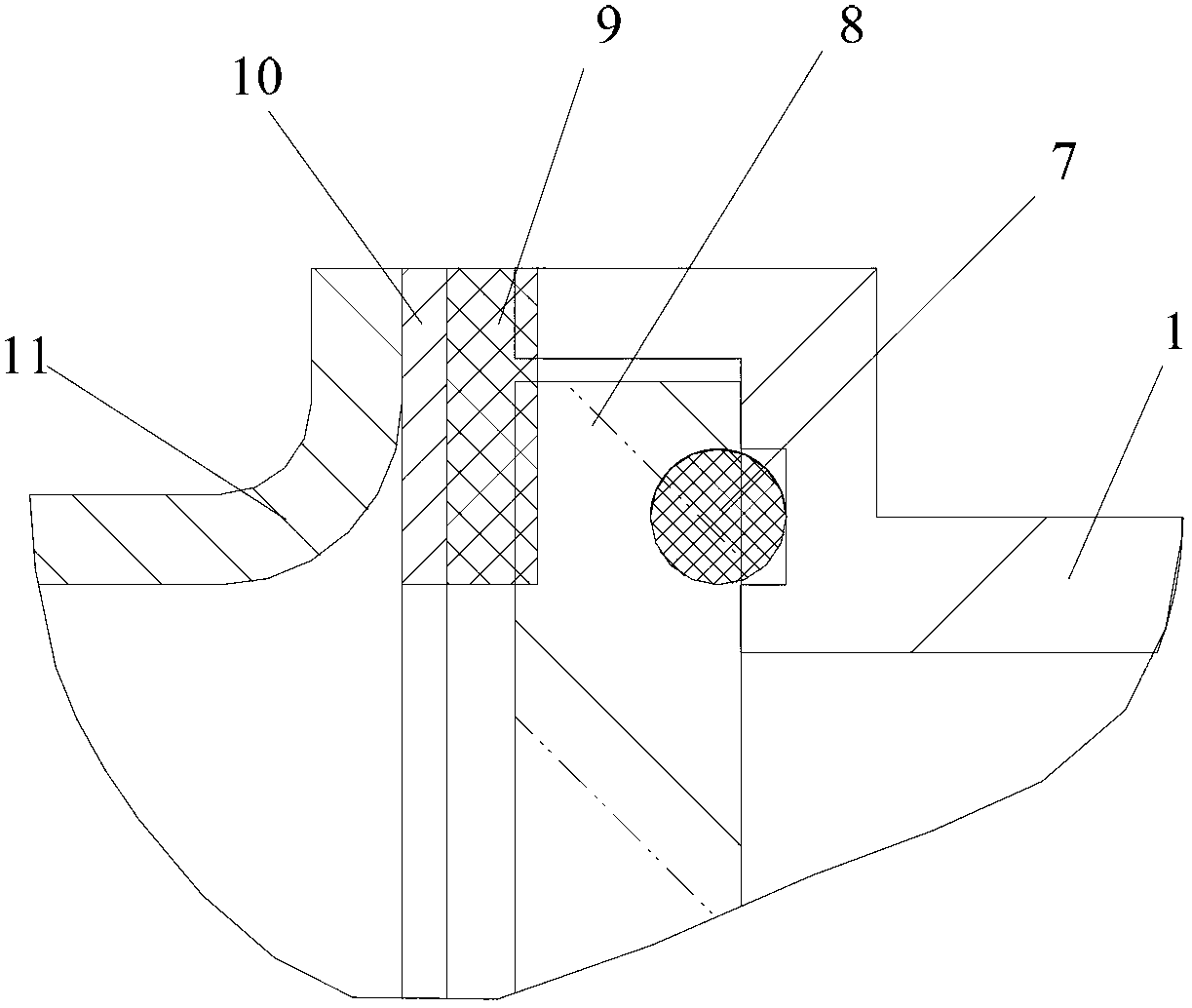

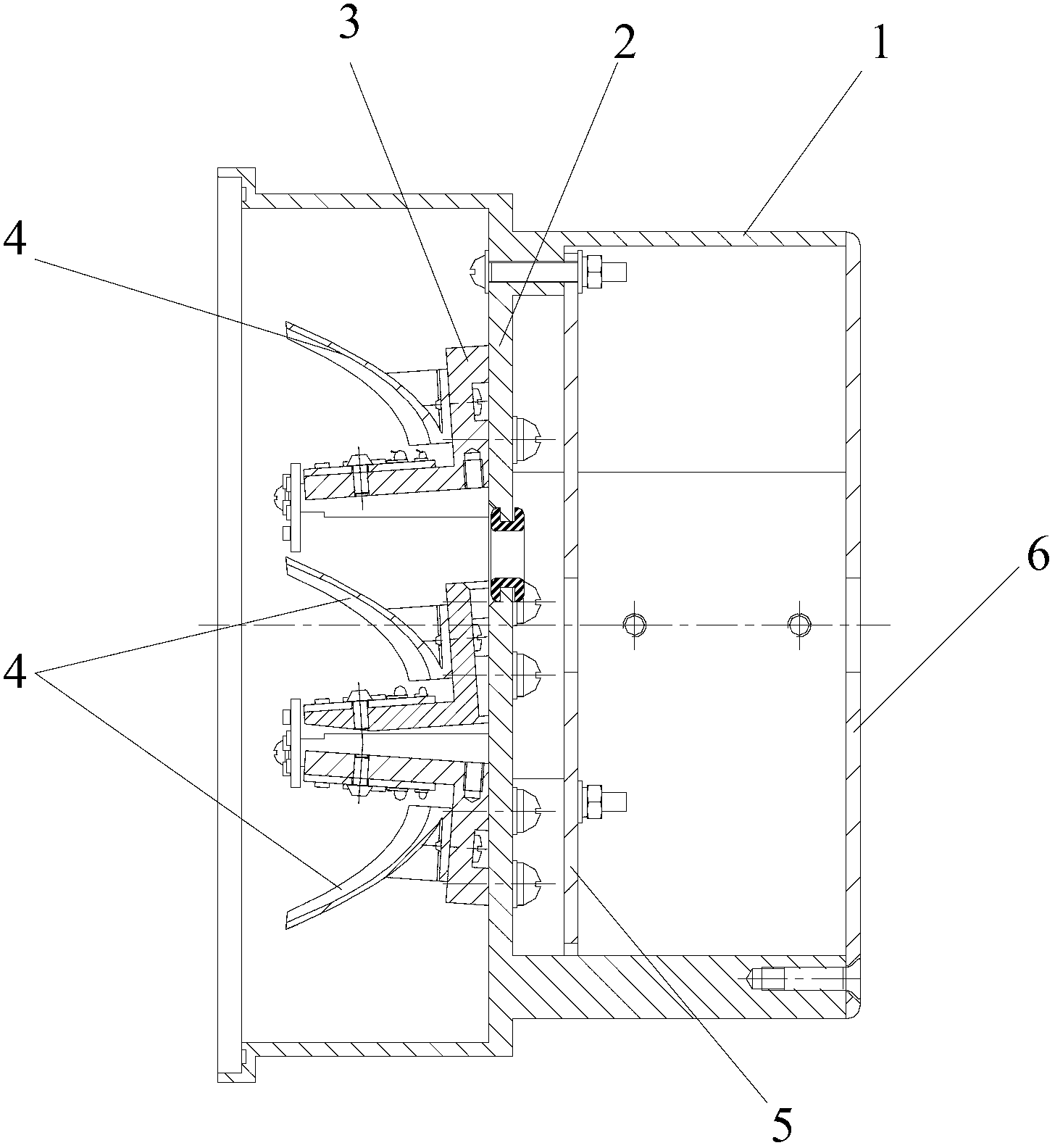

[0025] see figure 1 , the present invention comprises the lamp housing 1 that rear end is provided with rear cover 6, and lamp housing 1 is fastened on the car body of railway locomotive or motor car by mounting bracket 13 and fixed support 14; image 3 As shown, the inside of the lamp housing 1 is provided with a mounting plate 2 with a plurality of lamp holders 3, the angle between the surface of the lamp holder 3 on which the reflector 4 is installed and the surface of the mounting plate 2 is an acute angle of 4°, and the mounting plate 2 Divide the lamp housing 1 into two cavities, the front and the rear, and the cavity at the rear of the lamp housing 1 is sealed with glue; the lamp holder 3 is installed in the front cavity of the lamp housing 1, and the There is a column perpendicular to the mounting plate 2; the lamp holder 3 is L-shaped, and the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com