Heavy-duty vehicle wet multi-disc brakes

A heavy-duty vehicle and brake technology, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems that heavy-duty vehicles cannot be dragged, affect the service life of brakes, and are difficult to process and install. Reduce wear and heat, and facilitate processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

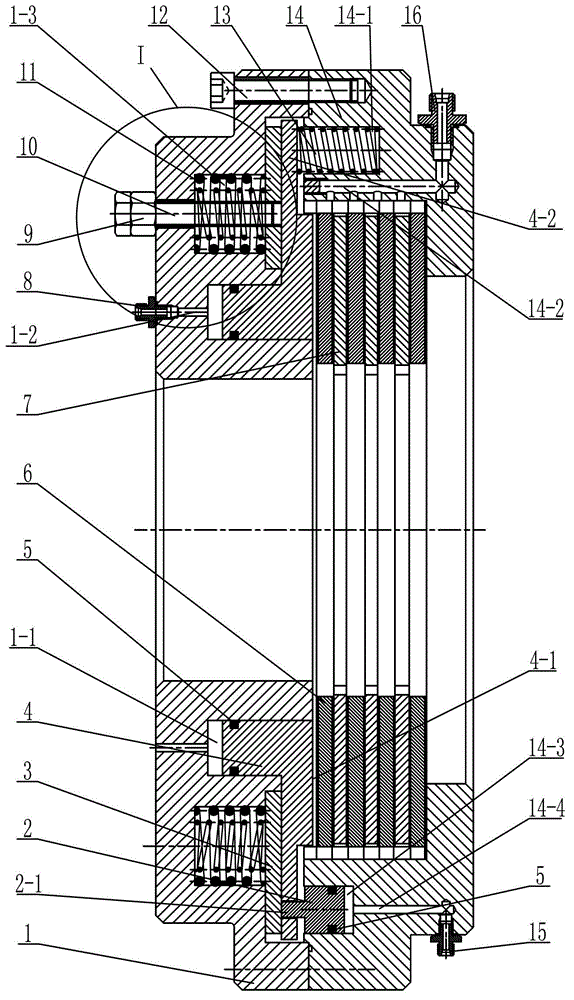

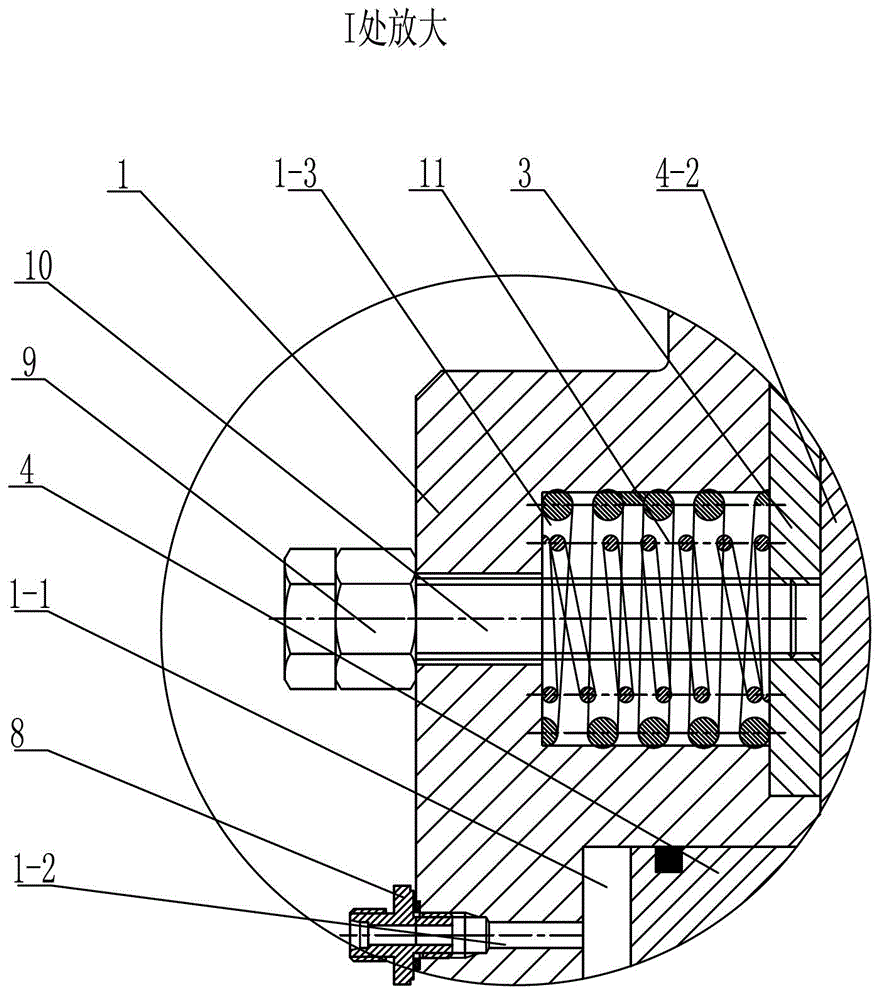

[0010] See figure 1 As shown, the heavy-duty vehicle wet multi-disc brake of the present invention includes a first housing 1 and a second housing 14 that are sealed and connected, and is arranged in the second housing 14 by a plurality of brake pads 6 and friction discs arranged at intervals in succession. The friction pair composed of plates 7, the first shell 1 and the second shell 14 are connected by a plurality of bolts 12, and a sealing ring is provided between the joint surfaces of the first shell 1 and the second shell 14, so that the first shell 1 and the second casing 14 form a closed casing, and the second casing 14 is located at the port of the lubricating oil passage 14-2, and a lubricating oil pipe joint 16 is installed so that the friction pair can be immersed in the lubricating oil, and the frictional torque is transmitted through the oil film , while achieving maintenance-free brake clearance. The brake disc 6 of the friction pair of the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com