Hydraulic auxiliary valve device and hydraulic valve device with the hydraulic auxiliary valve device

A technology for auxiliary valves and valve devices, applied in the field of hydraulic valve devices, can solve the problems of high wear risk of switching valves, expensive valves, and the inability to increase switching speed arbitrarily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

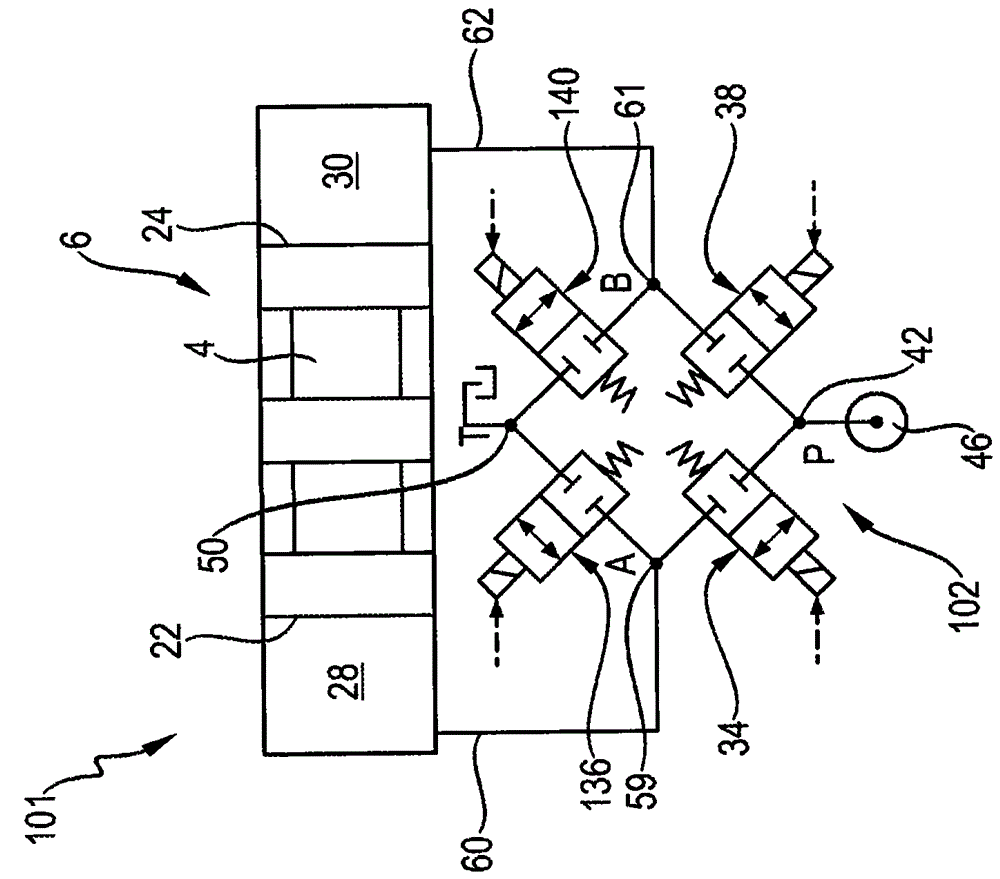

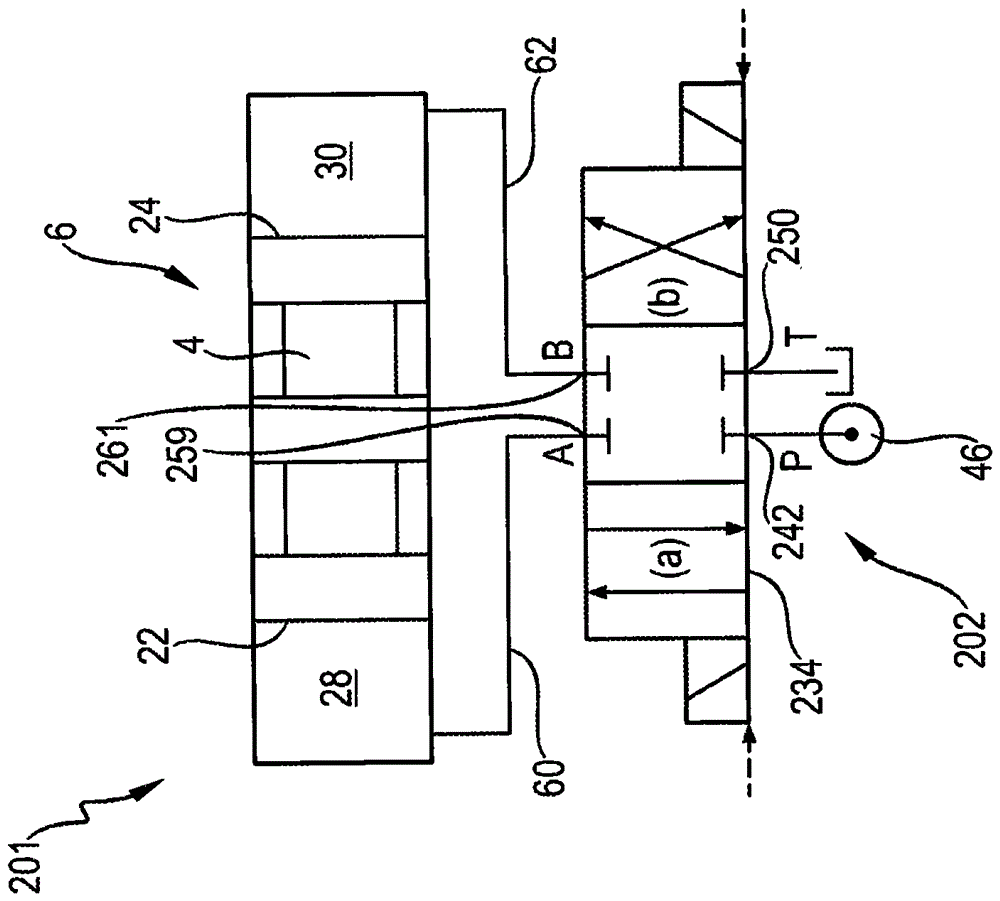

[0036] figure 1 Shown is a valve device 1 with an auxiliary valve device 2 which is flanged to a valve block 8 of a valve part 6 for actuating the valve body 4 or the valve part 6 configured as a 4 / 3 proportional directional valve. valve piston. Opposite the auxiliary valve arrangement 2 , an end disk 10 is flange-mounted on the valve block 8 . The valve part 6 has a high-pressure chamber 12 which can be connected to a high-pressure connection (not shown). Furthermore, the valve member 6 has low-pressure channels 14 and 16 which can be connected to a tank connection (not shown). In valve group 8 the figure 1 Two load connections 18 , 20 are arranged on the upper side in the middle, via which the valve element 6 can be connected to one or more loads.

[0037] according to figure 1 , the valve body 4 is in the central blocking position, so that the high-pressure chamber 12 is isolated from the load connections 18 , 20 and the low-pressure channels 14 , 16 . In the region o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com