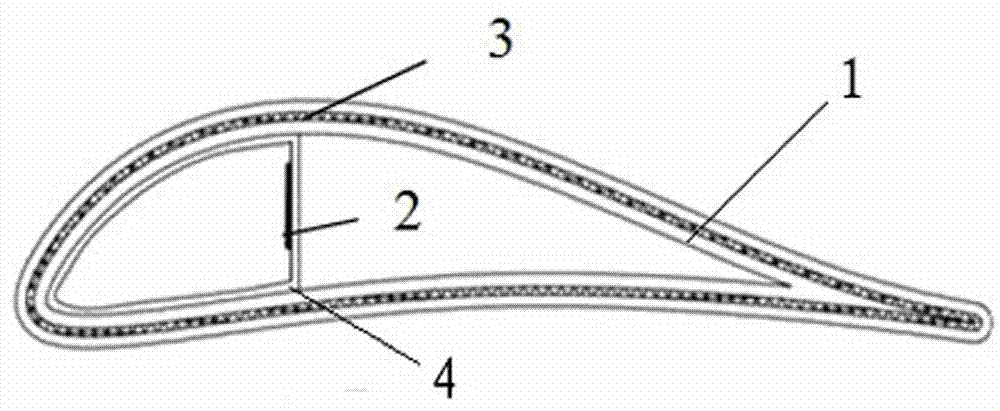

Method for restraining wind turbine blade adopting compound damping structure from vibrating

A technology of wind turbine blades and composite damping, which is applied to wind turbines, wind turbine components, engines, etc., can solve the problems of large flexible blades of wind turbines that are prone to flutter and lack of prevention methods, and achieve good vibration suppression performance and improved Aerodynamic stability, the effect of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Take a certain 2500 kW wind turbine as an example. The wind turbine is mainly used in offshore wind farms. Its design power is 2.5 MW. It adopts the form of three blades. The material of the leaf skin is GRP. The main design parameters are shown in Table 1.

[0057] serial number Design volume design value 1 Number of wind rotor blades 3 2 Speed / rpm 10.5~19.0 3 Rotor diameter / m 80 4 Frontal area / m 2 5 026 5 Power adjustment method variable pitch 6 Start wind speed / m / s 4 7 Rated power wind speed / m / s 15 8 Shutdown wind speed / m / s 25 9 Safe wind speed / m / s 65 10 pitch adjustment single drive 11 Total weight of wind wheel / kg 50 000 12 Blade length / m 38.8 13 Blade weight / kg 8 700 14 blade material GRP

[0058] (1) airfoil selection

[0059] According to the design requirements, the NACA 6413 airfoil is selected for the entire blade, which has a large lift-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com