Construction method for directional expansion-rise deviation rectification

A construction method and deviation correction technology, which is applied in the field of building deviation correction in civil engineering, can solve problems such as stress concentration, high risk, and high cost, and achieve the effects of overcoming deviation correction stress concentration, simple construction equipment, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

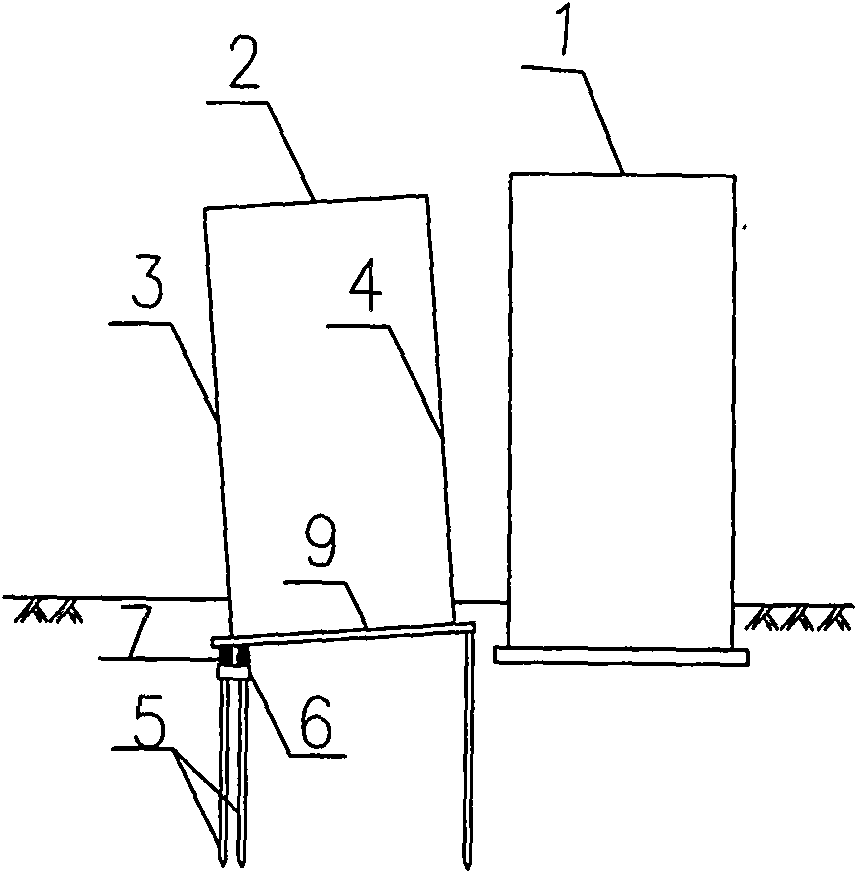

[0017] As the directional expansion correction method of the present invention such as figure 1 and figure 2 An embodiment shown mainly introduces the construction process and steps of this deviation correction method. exist figure 1 In the first stage shown, at first, according to the verticality observation data, it is determined that the inclined building (2) is inclined in the opposite direction to the adjacent building (1), and the first stage of this embodiment of the directional swelling correction method is completed, that is, the building is determined Then enter the second stage of this embodiment of the directional expansion and rectification method. After investigation, the inclined building (2) adopts natural foundation, and it is necessary to correct the deviation of the inclined building (2). Due to the existence of the adjacent building (1) and its closeness to the inclined building (2), the deviation correction process There is no construction operation su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com