Ski-jump and jet flow combined energy dissipation device

A technology of energy dissipation device and test device, which is applied in water conservancy projects, sea area projects, coastline protection, etc., and can solve problems such as restrictions on the use of scour pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

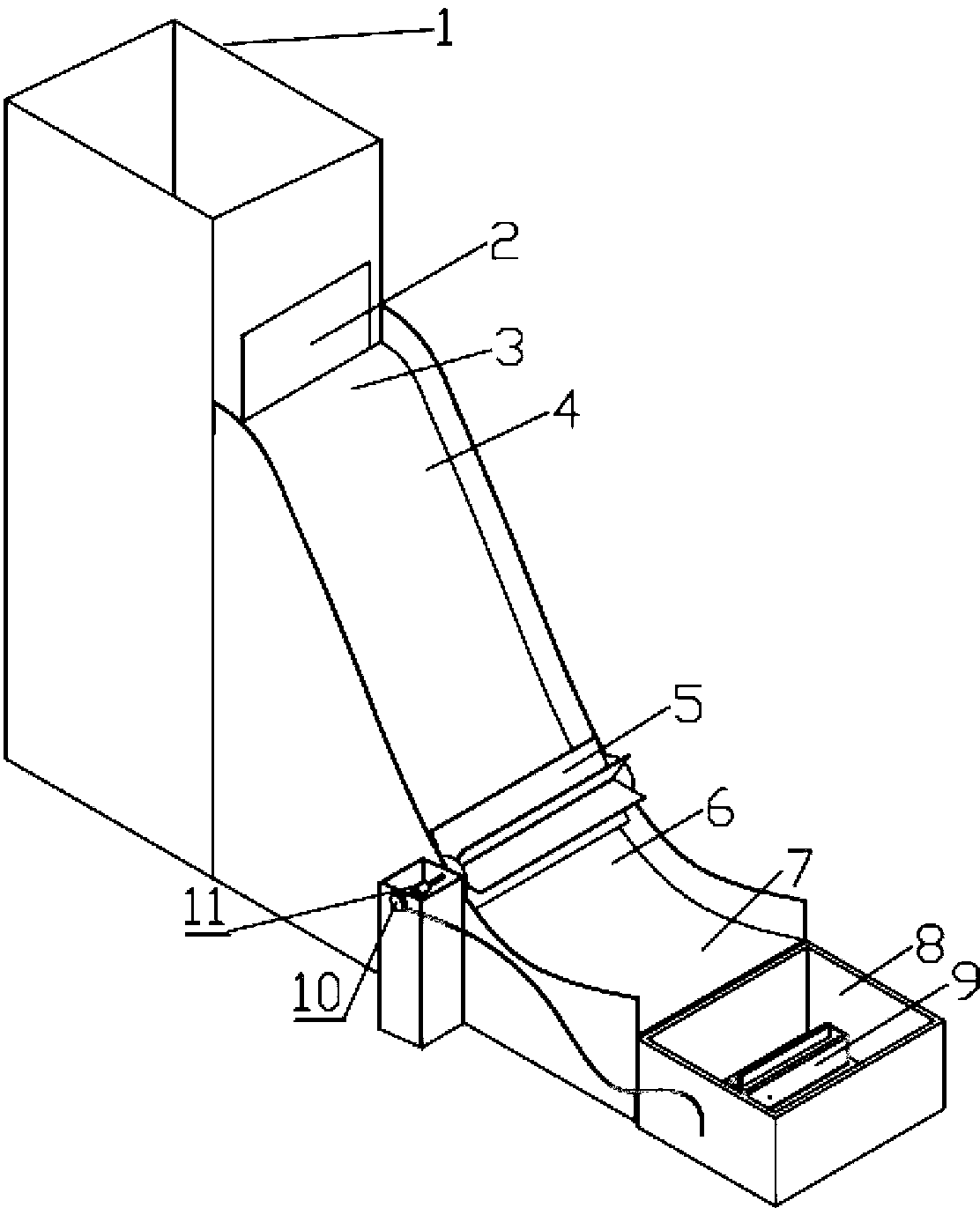

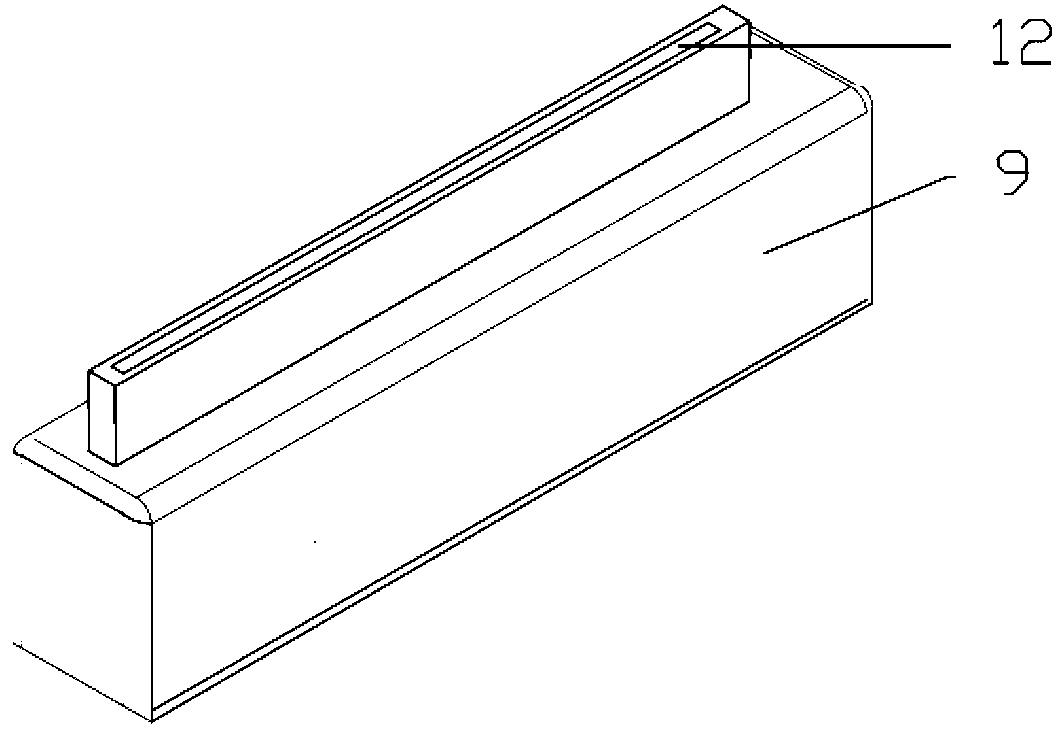

[0012] Such as Figure 1~2 As shown, the device is composed of a reservoir, a dam body, a dam surface, an impeller, a generator, a high-pressure water pump, a cushion pond, a bearing, a coupling, and a transmission.

[0013] The water outlet 2 of the reservoir is consistent with the top 4 of the dam. When the water in the reservoir 1 reaches a certain amount, the water in the reservoir 1 will be stably discharged from the top 4 along the dam surface 3 in the form of surface flow. Form a surface flow. The nose sill part of the dam surface is composed of a circular arc section 6 with a central angle of 53° and a circular arc section 7 with a scoop angle of 25°, which realizes the turning of the water flow and the protruding surface does not produce excessive impact on the dam. The impeller 5 is composed of 5 blades with a length×width of 600 mm×105 mm, and the left and right sides of the impeller are circles with a radius of 65 mm. The lowest point of the impeller blades is 5mm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com