Bobbin yarn middle sample dyeing machine

A dyeing machine and bobbin technology, which is applied in the direction of dyeing device for processing textile materials, equipment configuration for processing textile materials, etc., can solve the problems of inconsistent temperature and pressure, easy leakage of dye solution, unstable dyeing, etc., and achieve automatic temperature control and increase Product quality, compact structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

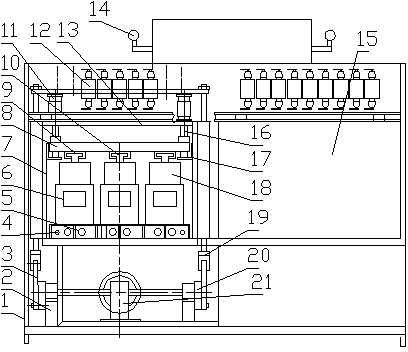

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

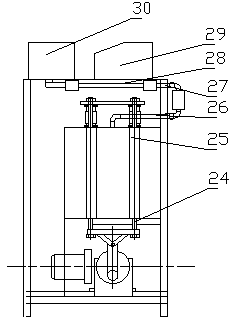

[0015] With reference to the accompanying drawings, the package dyeing machine includes a fuselage 1, a dyeing cup 18, and a water tank 30, and is characterized in that a dyeing vat 7 is arranged in the middle of the fuselage 1, and several cup holders are arranged in the dyeing vat 7 6. The cold water pipe 4 and the heating pipe 5 are arranged under the cup holder 6, and the creel 10 is arranged through the dyeing cup 18 inside the cup holder 6, and angle irons 17 are arranged on both sides of the dyeing vat 7, and angle irons 17 are respectively welded with Two fixed columns 16, the fixed column is covered with a dyeing vat fixing frame 8 and a sealed telescopic tube 11; under the dyeing vat fixing frame 8, a number of yarn rack fixing plates 9 are arranged; two guide sleeves are arranged symmetrically on the outside of the dyeing vat 7 25; double output shaft motors 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com