Dislocation starting device of coke oven cover and application method of dislocation starting device

A technology for opening devices and furnace lids, which is applied in the heating of coke ovens, doors/closers of coke ovens, coke ovens, etc., and can solve the problems affecting the stable and normal production of coke ovens, affecting the stable production of furnace bodies, and damage to furnace body components, etc. problems, to avoid hard damage to the furnace body, to prevent flue gas from escaping, and to achieve the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

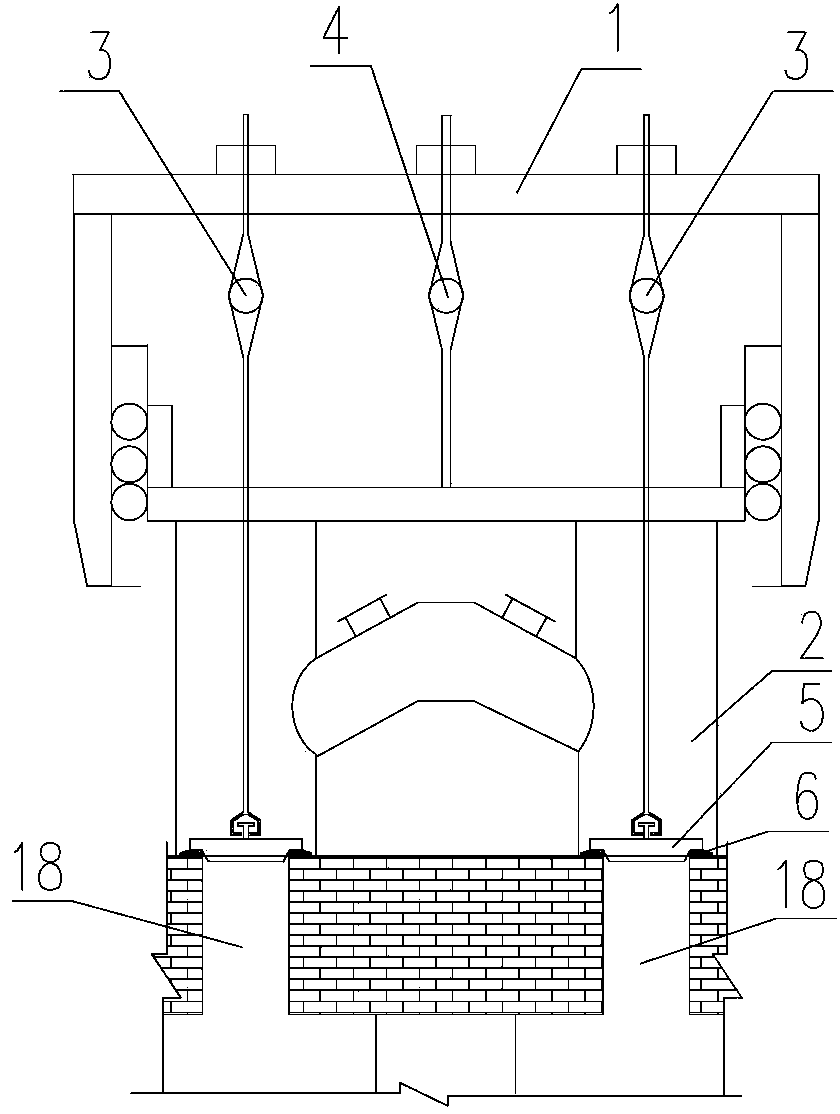

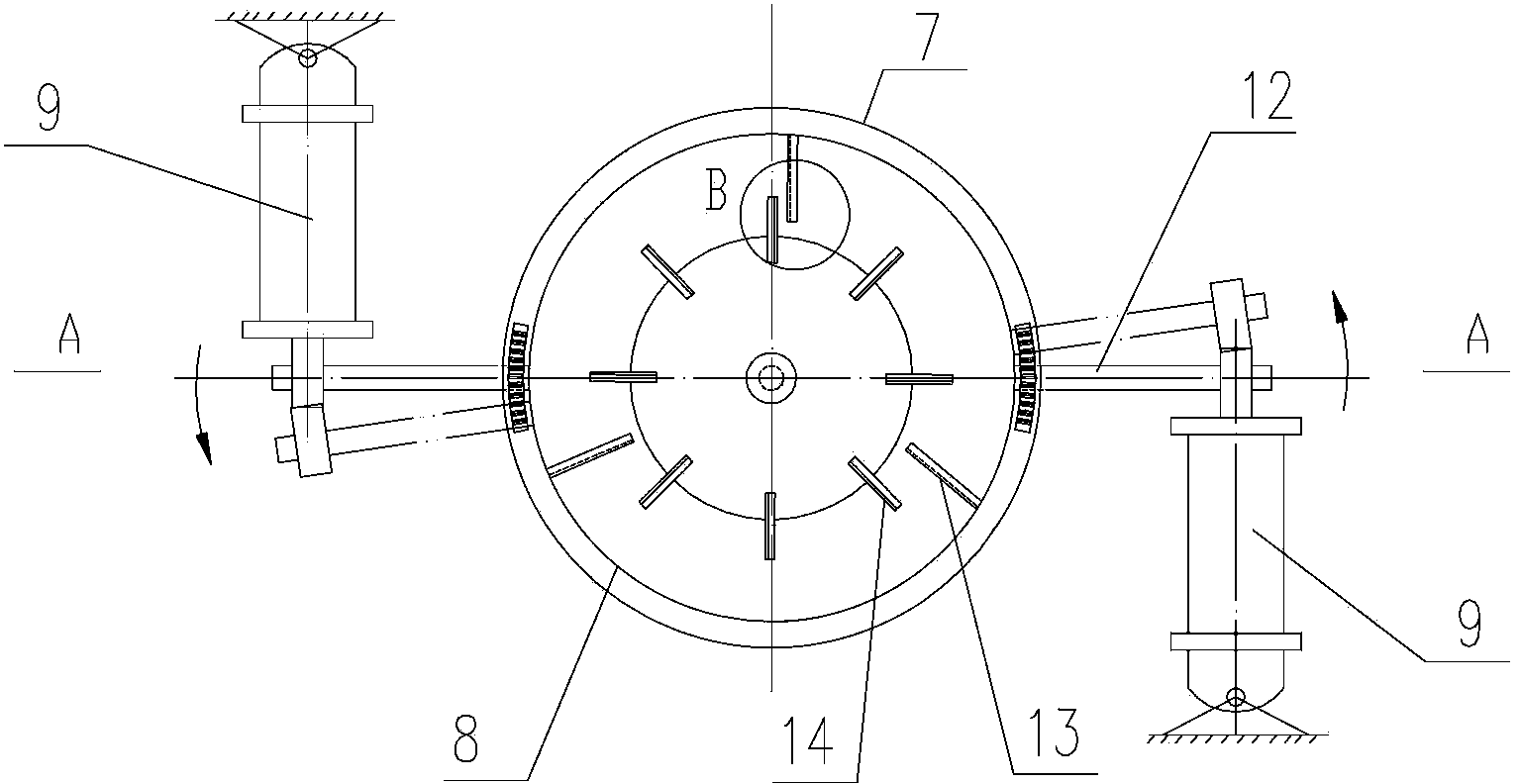

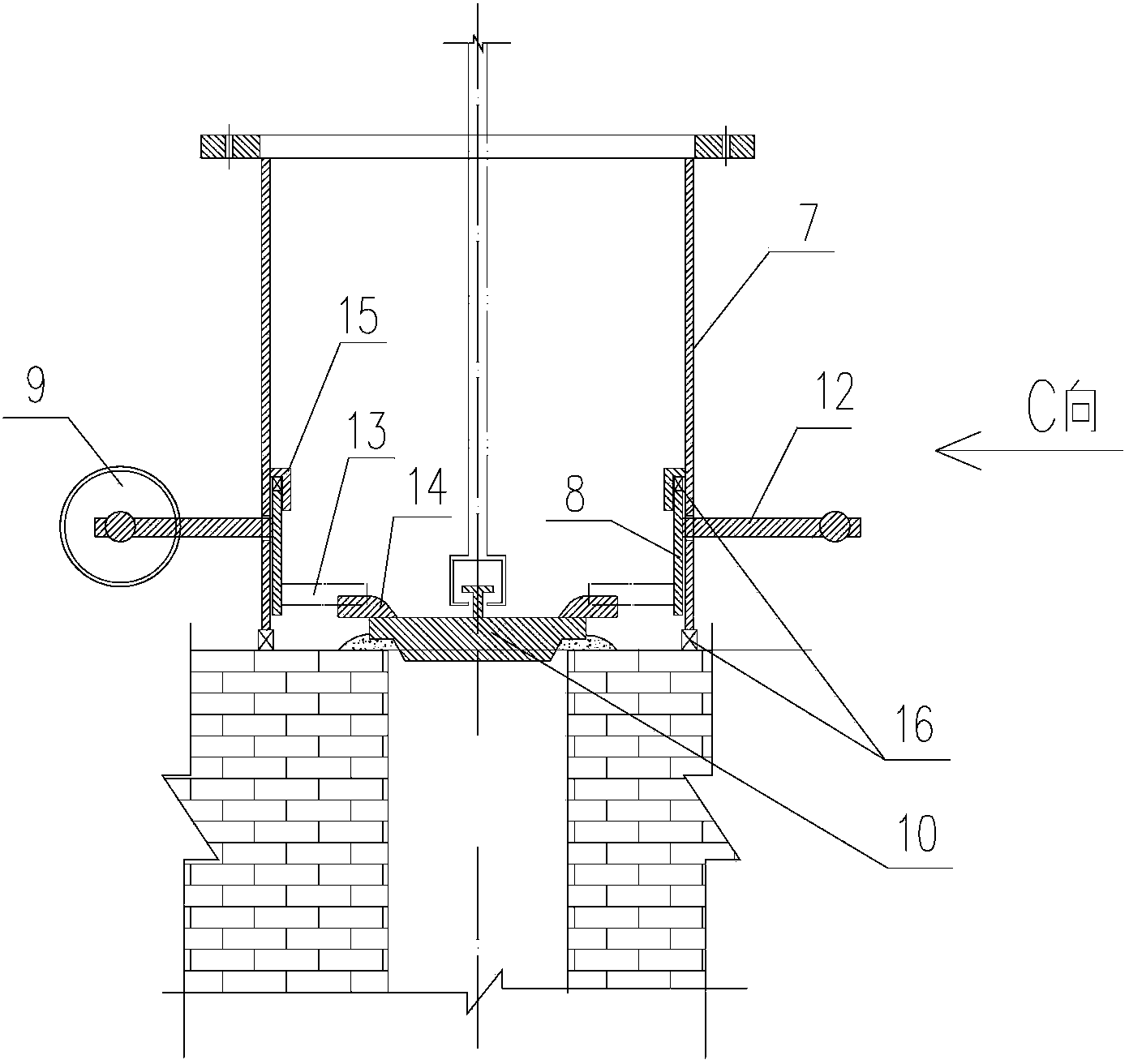

[0033] See Figure 2 to Figure 5 , is a structural schematic diagram of an embodiment of a staggered opening device for a coke oven cover of the present invention, including an outer sleeve 7, a staggered sleeve 8, a cylinder 9 and an ear handle furnace cover 10, and the outer sleeve 7 is sleeved on the staggered sleeve 8, the inner wall of the outer sleeve 7 is slidably matched with the outer wall of the staggered sleeve 8, and the outer sleeve 7 is provided with at least two oblong through holes 11 along the circumferential direction. The outer wall of the staggered sleeve 8 corresponding to the hole is provided with a push rod 12, and the outer side of the outer sleeve 7 is provided with a cylinder 9, the end of the piston rod of the cylinder 9 is hinged with the end of the push rod 12, and the Several push handles 13 are arranged on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com