Method for preparing carbon nanometer paper enhanced conductive polymer matrix composite material

A technology of conductive polymer and carbon nanopaper, which is applied in the field of preparation of conductive polymer-based composite materials reinforced by carbon nanopaper, can solve the problems of increased viscosity of polymer matrix, limited content of carbon nanotubes added, and difficulty in forming composite materials. , to increase the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

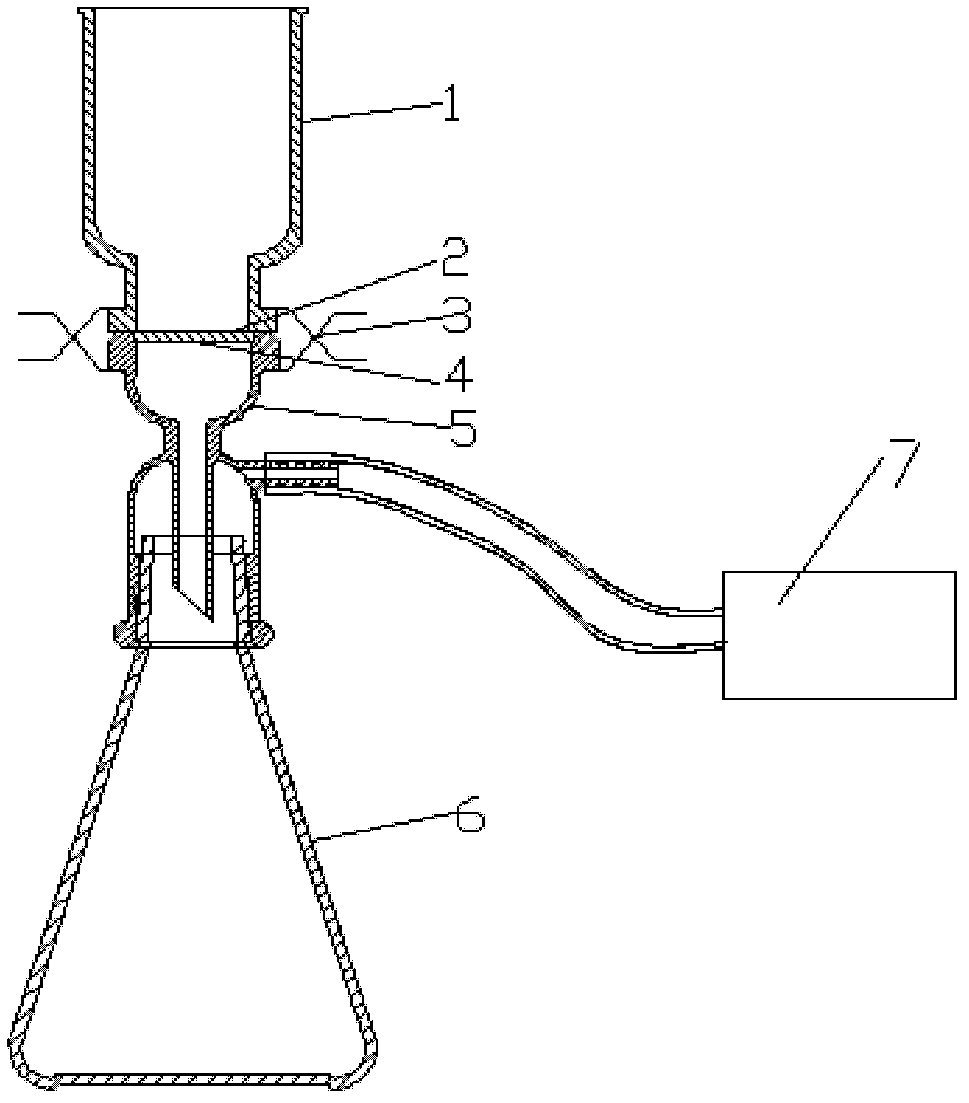

Image

Examples

Embodiment 1

[0034] Carbon nanopaper is a film-like self-supporting three-dimensional structure composed of carbon nanotubes (single-walled or multi-walled) molecules connected by Van der Waals force, which has high electrical conductivity and air permeability. , electromagnetic properties and mechanical properties, can be widely used in carbon nanotube sensors, artificial muscles, electrodes, strain sensors, permeable membranes and multifunctional composite materials and other fields.

[0035] Graphene is a new type of two-dimensional nano-carbon material composed of a layer of carbon atoms, and is currently the thinnest two-dimensional material in the world. The strength of graphene material is the highest among known materials, and its conductivity and current-carrying density are both higher than the current best single-walled carbon nanotubes, and its excellent quantum Hall effect (Quantua Hall effect) has also been proved. After mixing the solution of graphene oxide with carbon nanot...

Embodiment 2

[0051] (1) Mix commercially available single-walled carbon nanotubes with sodium dodecylsulfonate in a ratio of 1:1, the single-walled carbon nanotubes have a diameter of 6-10 nm and a length of 15-20 μm;

[0052] (2) Put the mixture of single-walled carbon nanotubes and sodium dodecyl sulfonate into a mortar and grind for 1-60min, pour into a beaker, add plasma water until the concentration of single-walled carbon nanotubes is 0.01wt%, and the surface dispersant concentration 0.01wt%;

[0053] (3) Pour the mixed solution into a magnetic stirrer, control the temperature at 10-60°C, and disperse for 15-60min;

[0054] (4) Defoaming for 10-100 minutes;

[0055] (5) Get graphene oxide (the mass ratio of carbon nanotube: graphene is 10: 3) and join in plasma water, be mixed with the solution of concentration 0.8mg / ml, ultrasonic dispersion 30-60min; Others are with embodiment 1.

Embodiment 3

[0057] (1) Get commercially available hydroxylated carbon nanotubes and sodium dodecylsulfonate and sodium dodecylbenzenesulfonate, mix in a ratio of 1: (10+10), and the diameter of hydroxylated carbon nanotubes is 16- 25nm, length 25-40μm;

[0058] (2) Put the mixture of hydroxylated carbon nanotubes, sodium dodecylsulfonate and sodium dodecylbenzenesulfonate into a mortar and grind for 1-60min, pour into a beaker, add plasma water to the concentration of hydroxylated carbon nanotubes is 0.02wt%, and the surface dispersant concentration is 1wt%;

[0059] (3) Pour the mixed solution into a magnetic stirrer, control the temperature at 10-60°C, and disperse for 15-60min;

[0060] (4) Defoaming for 10-100 minutes;

[0061] (5) Get graphene oxide (the mass ratio of carbon nanotubes: graphene is 10: 2) and add it into plasma water, prepare a solution with a concentration of 0.5 mg / ml, and ultrasonically disperse it for 30-60 min;

[0062] Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com