Electric actuator

A technology of electric actuator and electric motor, which is applied in electric steering mechanism, power steering mechanism, and manufacturing of motor generators, etc., can solve the problems of reduced electrical connectivity, small elastic force, and inability to obtain large holding force, and achieves restraint Reduced electrical connectivity, effect of stable and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

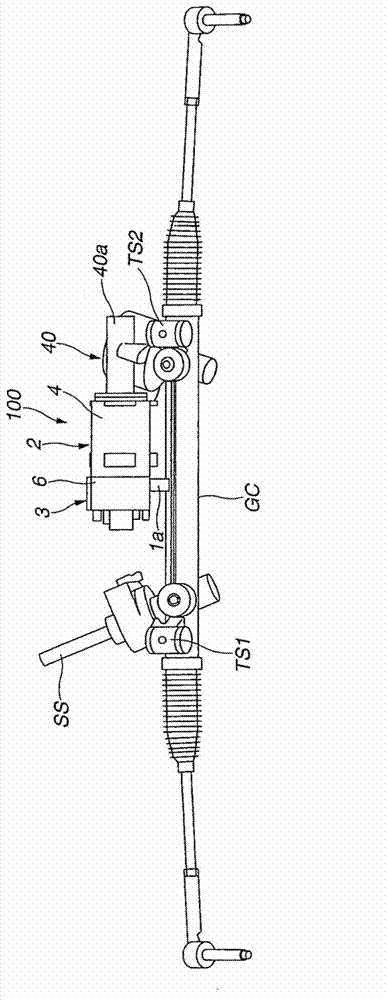

[0058] like image 3 As shown, the electric power steering device is provided with a gear box GC inside which accommodates a rack and a pinion on the front end side of the steering shaft SS, and at one end of the gear box GC where the front end of the steering shaft SS is located A torque sensor TS that detects the rotational torque of the steering shaft SS is provided. In addition, an electric actuator 1 that assists the rotational force of the steering shaft SS is provided on a side portion of the gearbox GC via a bracket 1a, and an electric actuator 1 that supports the electric actuator 1 is provided on the other end portion. The second torque sensor TS that detects the rotational torque.

[0059] like Figure 3 ~ Figure 5 As shown, the electric actuator 1 includes: a motor unit 2 arranged on the central side; a control unit 3 (ECU) arranged on one end side of the motor unit 2; a speed reduction mechanism 40 arranged on the other end side of the motor unit 2 .

[0060] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com