Electrochemical machining method for auxiliary anode tube electrode

A processing method and auxiliary anode technology, applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the processing accuracy of hole exits, reducing the consistency of group hole exits, and the processing of holes successively. Improvement of hole outlet uniformity, suppression of stray corrosion, effect of stray corrosion suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

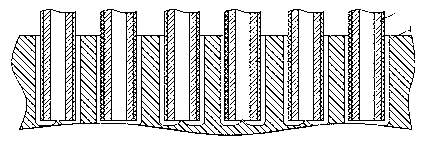

[0035] figure 1 In the process, due to the uneven thickness of the parts, the group holes appear successively through;

[0036] figure 2 In the case of excessive feeding, secondary corrosion will occur in the hole that penetrates first, forming a trumpet-shaped outlet 8;

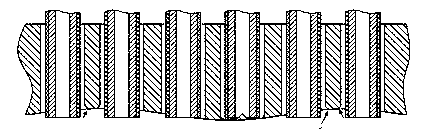

[0037] Figure 4 , Figure 5 In the schematic diagram of the electrolytic machining of the auxiliary anode tube electrode shown, the auxiliary anode 6, the porous plate 5, and the workpiece anode 4 are installed on the substrate holder 7 through the positioning pin 9, and connected to the circuit. Wherein the through hole of the perforated plate is facing the exit position of the hole to be processed.

[0038] combine Figure 4 , Figure 5 The implementation process of the present invention is described:

[0039] Step 1, preparing a porous plate 5 consistent with the holes to be processed;

[0040] Step 2, sequentially arrange the workpiece anode 4, porous plate 5, and auxiliary anode 6 on the substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com