A kind of method for preparing w-cu system gradient composite material by casting method

A technology of composite materials and tape casting method, which is applied in the field of preparation of W-Cu system gradient composite materials by tape casting method, can solve the problem of few gradient composite materials in metal system, achieve continuous controllability of components, good electrothermal properties, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

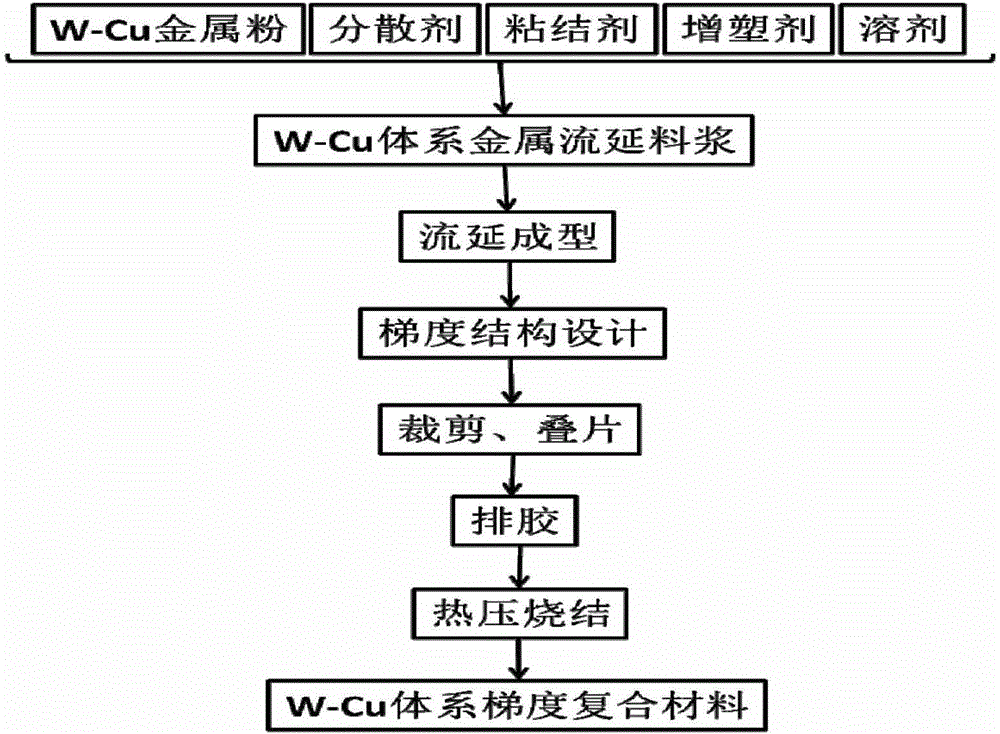

[0034] Such as figure 1 Shown, the preparation method of W-Cu system gradient composite material, it comprises the steps:

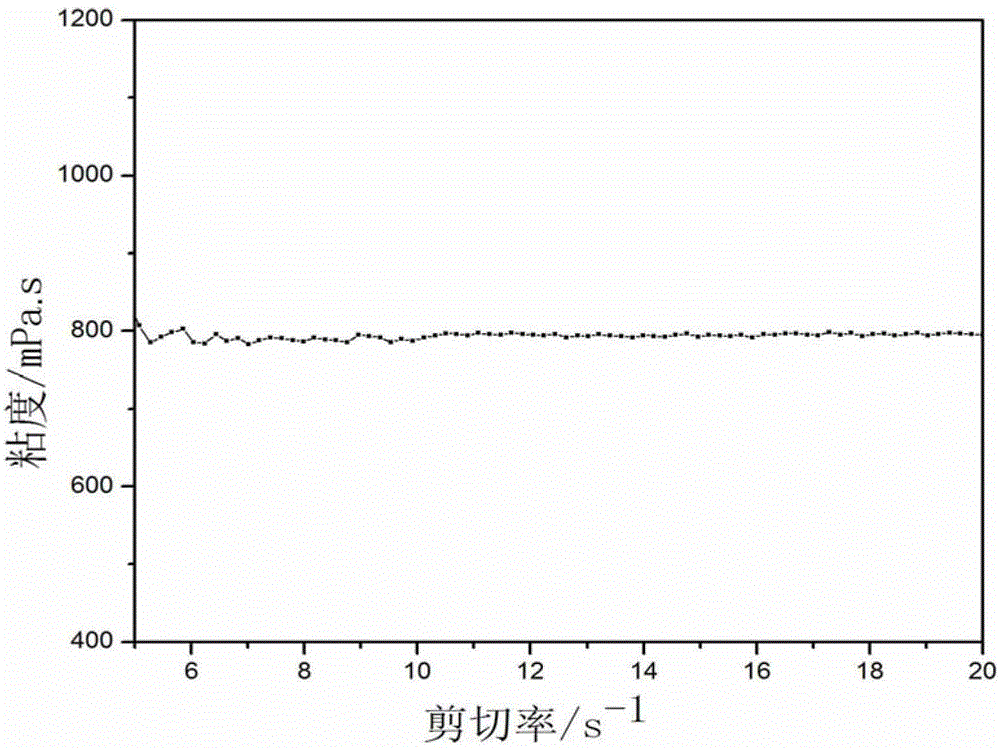

[0035]1) Preparation of casting slurry: the mass percentage of each raw material is: the solid phase content of Cu powder with a particle size of 10 μm is 60%, the dispersant Hypermer KD-1 is 1%, the binder polyvinyl butyral 3%, plasticizer glycerin 3.2%, methyl ethyl ketone solvent 32.8%; Solvent, dispersant Hypermer KD-1, Cu powder, binder and plasticizer are put into nylon ball mill jar, with agate ball as ball mill medium, The ball-to-material ratio is 1:1, and the ball mill is mixed for 24 hours on a ball mill to obtain a mixed slurry; after the ball-milled mixed slurry is degassed (use a small defoamer for vacuum filtration) and filtered, the pure Cu can be obtained Powder non-water-based casting slurry, its rheological properties are as follows figure 2 As shown, the viscosity basically does not change with the rotation speed, indicating that th...

Embodiment 2

[0041] Such as figure 1 Shown, the preparation method of W-Cu system gradient composite material, it comprises the steps:

[0042] 1) Preparation of casting slurry: the mass percentage of each raw material is: the solid phase content of copper powder with a particle size of 10 μm is 60%, the dispersant Hypermer KD-1 is 1%, the binder polyvinyl butyral 3%, plasticizer glycerin 3.2%, methyl ethyl ketone solvent 32.8%; Solvent, dispersant Hypermer KD-1, Cu powder, binder and plasticizer are put into nylon ball mill jar, with agate ball as ball mill medium, The ball-to-material ratio is 1:1, and the ball mill is mixed for 24 hours on a ball mill to obtain a mixed slurry; after the ball-milled mixed slurry is degassed (use a small defoamer for vacuum filtration) and filtered, the pure Cu can be obtained Powder non-water-based casting slurry.

[0043] 2) Tape casting: inject the pure Cu powder slurry obtained in step 1) into the casting machine, adjust the height of the scraper to...

Embodiment 3

[0048] Such as figure 1 Shown, the preparation method of W-Cu system gradient composite material, it comprises the steps:

[0049] 1) Preparation of casting slurry: the mass percentage of each raw material is: the solid phase content of Cu powder with a particle size of 10 μm is 60%, the dispersant Hypermer KD-1 is 1%, the binder polyvinyl butyral 3%, plasticizer glycerin 3.2%, methyl ethyl ketone solvent 32.8%; Solvent, dispersant Hypermer KD-1, Cu powder, binder and plasticizer are put into nylon ball mill jar, with agate ball as ball mill medium, The ball-to-material ratio is 1:1, and the ball mill is mixed for 24 hours on a ball mill to obtain a mixed slurry; after the ball-milled mixed slurry is degassed (use a small defoamer for vacuum filtration) and filtered, the pure Cu can be obtained Powder non-water-based casting slurry.

[0050] 2) Tape casting: inject the pure Cu powder slurry obtained in step 1) into the casting machine, adjust the scraper height to 1.0mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com