Spherical swing device for large rotary forging press

A technology of swing device and rotary rolling machine, which is applied in the direction of transmission device, friction transmission device, forging/pressing/hammer device, etc., which can solve the problems of strain, damage, and restriction of large-scale rotary rolling machine research and development, and achieve friction The effect of reducing and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

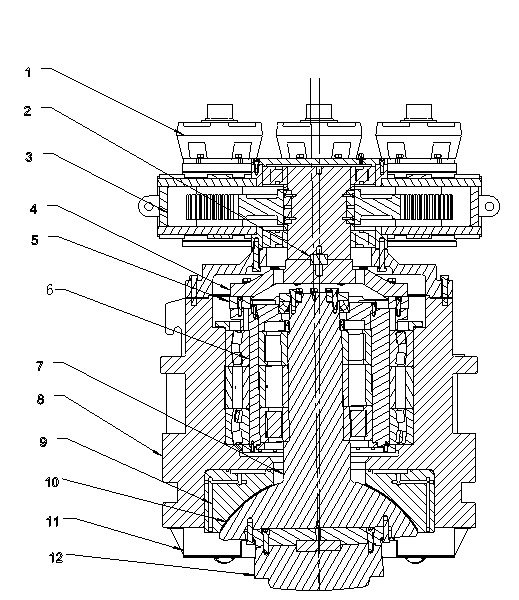

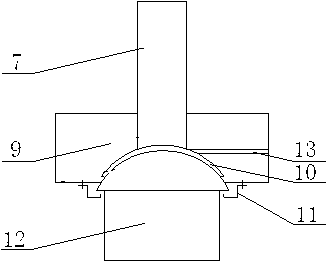

[0016] Example: such as figure 1 , 2 As shown, a spherical oscillating device for a large-scale rotary rolling machine includes a fixed seat 8 and a drive gearbox 3 and an oil motor 1 fixed on the top thereof. The drive gearbox 3 drives the long key 2 and the connecting plate 4 It is fixedly connected with the deflection sleeve shaft system 6 in the fixed seat 8. The center of the deflection sleeve shaft system 6 is the swing main shaft 7, and the lower end of the swing main shaft 7 is a ball head and a swing head 12, and passes through the ball head and the ball bowl 9. Cooperate to realize the rotation connection, the surface of the ball bowl 9 is provided with a layer of polymer wear-resistant layer 10, and an oil inlet hole 13 is also provided on the ball bowl 9 to pass directly from the outside to the contact surface of the ball head and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com