Sizing machine pasting table modular structure

A modular, paste-table technology, used in coatings, devices for applying liquid to surfaces, etc., can solve problems such as water rust, reduce maintenance costs, provide rigidity, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

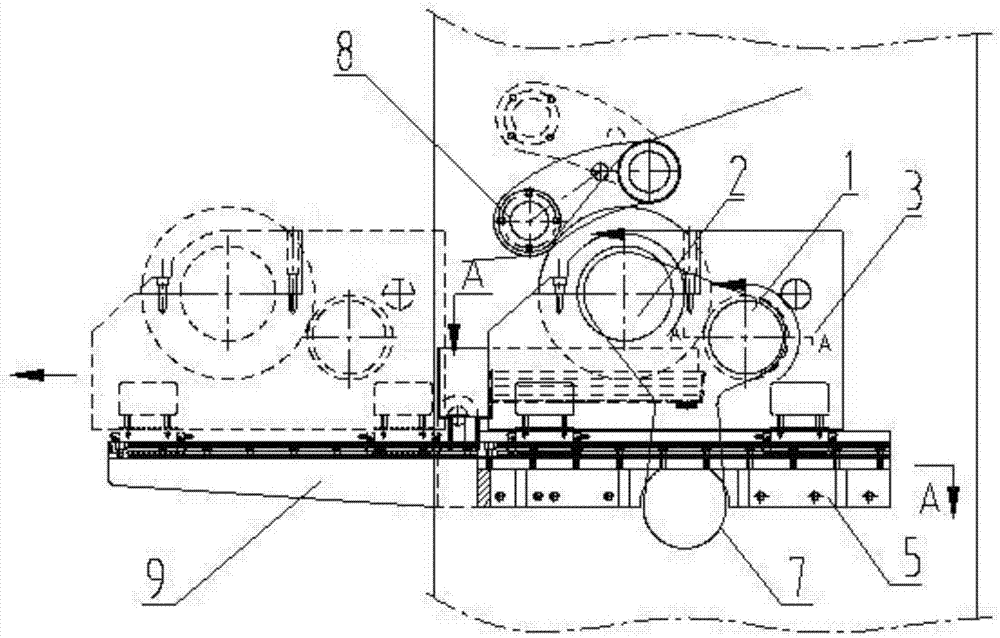

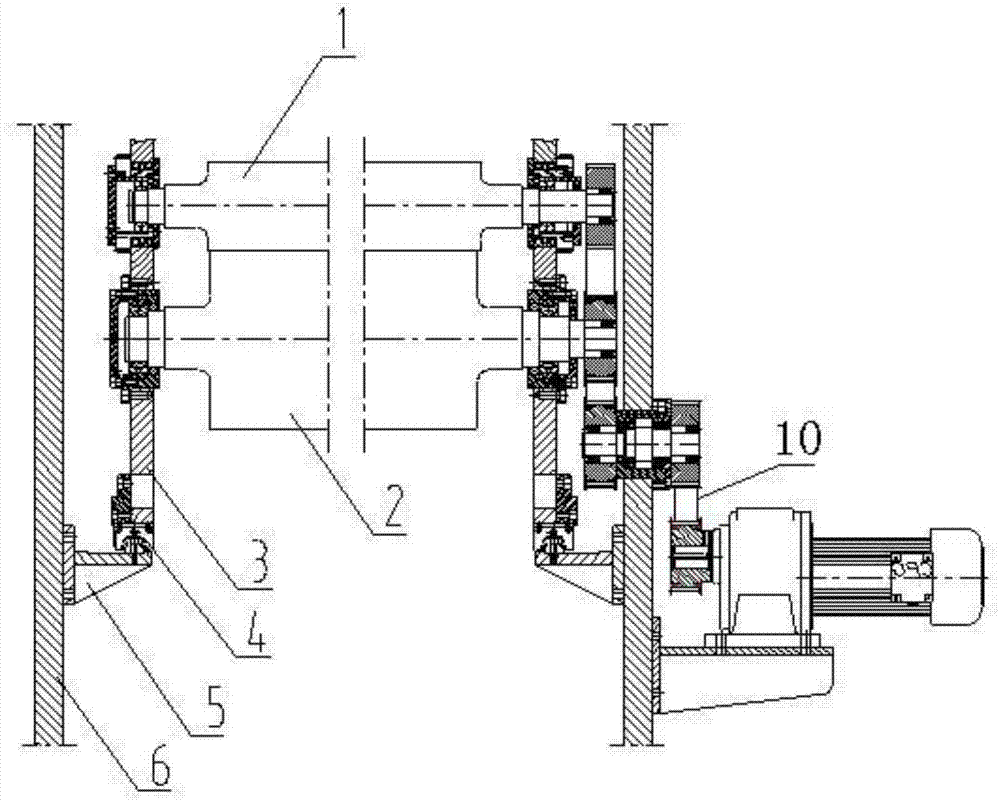

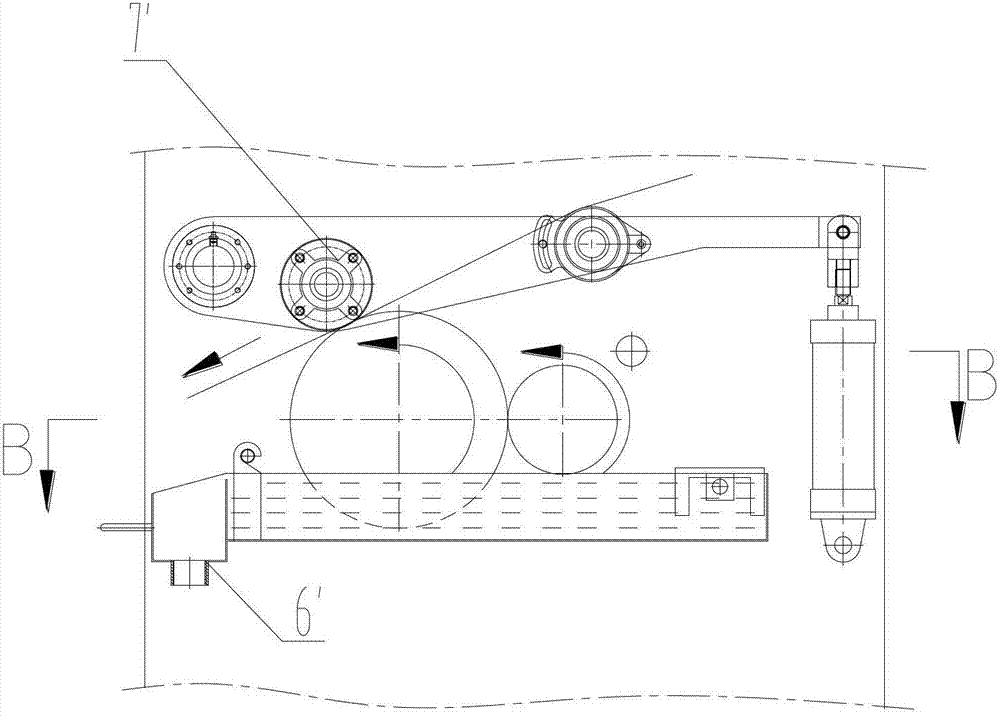

[0020] Such as figure 1 , 2 As shown, the side walls 3 of the pasting table are Hough-type structures, and the two side walls 3 of the pasting table are buckled and assembled, fastened with screws and positioned with pins. The pulp control roller 1 and the sizing roller 2 are installed on the side wall 3 of the pasting table through bearings and expansion sleeves. One end of the pulp control roller 1 and the sizing roller 2 is respectively installed with a driven wheel, and a drive shaft is installed on the side wall of the paste table. The two ends of the drive shaft The drive wheel is installed at one end, and the motor is fixedly installed under the drive shaft outside the side wall of the pasting table. The synchronous belt 2 10 outputs the rotation of the motor spindle to the drive wheel, and the other end of the drive wheel als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com