A kind of production equipment and process of fire-resistant power cord

A technology for producing equipment and power cords, applied in coatings, household appliances, household components, etc., can solve the problems of time-consuming and laborious, increasing the workload of staff, and inconvenient discharge of water in the sink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

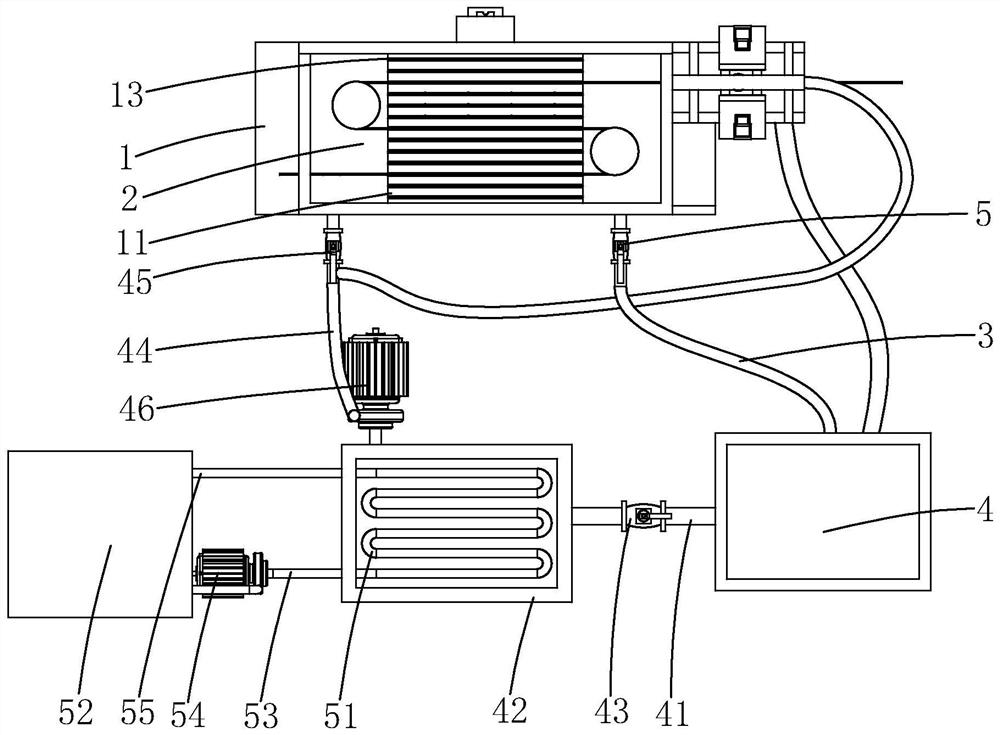

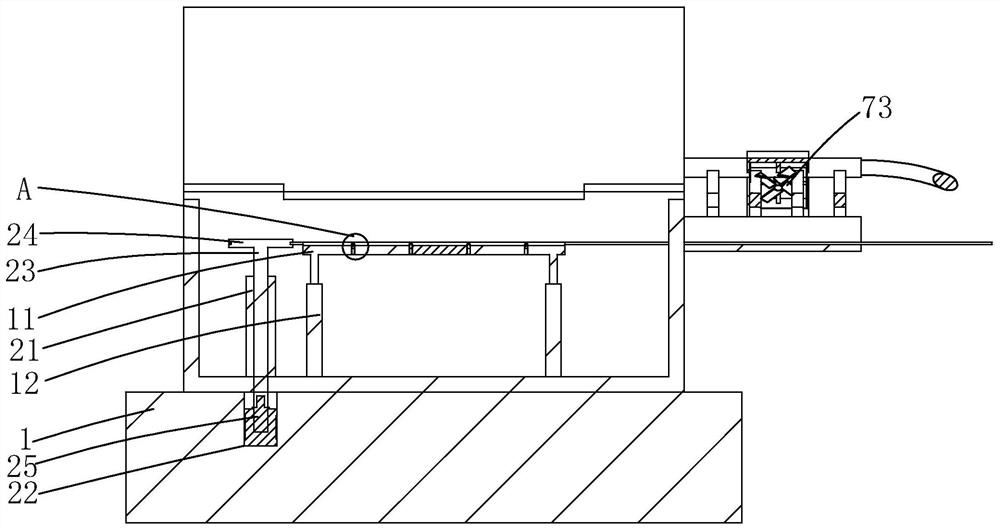

[0043] refer to figure 1 and Figure 4 , is a kind of fire-resistant power cord production equipment disclosed by the present invention, comprising: an inlet, a forming section, an extrusion section, an outlet, a stretching device and a cooling device. In this embodiment, the cooling device includes: a support platform 1 , a cooling pool 2 , a water outlet hose 3 , a water storage tank 4 and an electric switch valve 5 . The support platform 1 is set on the ground; the cooling pool 2 is hinged on the bearing surface of the support platform 1, and the cooling pool 2 is filled with water for cooling the fire-resistant power cord, and the inlet and outlet holes are provided on the opposite sides of the cooling pool 2 hole, the refractory power cord can go in and out from the wire hole; the water outlet hose 3 is installed on one side of the opposite sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com