Fan-shaped rotary film separation device

A membrane separation and rotary technology, applied in the field of membrane separation, can solve the problems of increased production costs, small filtration flux, and low packing density, and achieve strong anti-fouling ability, high filtration flux, and high packing density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

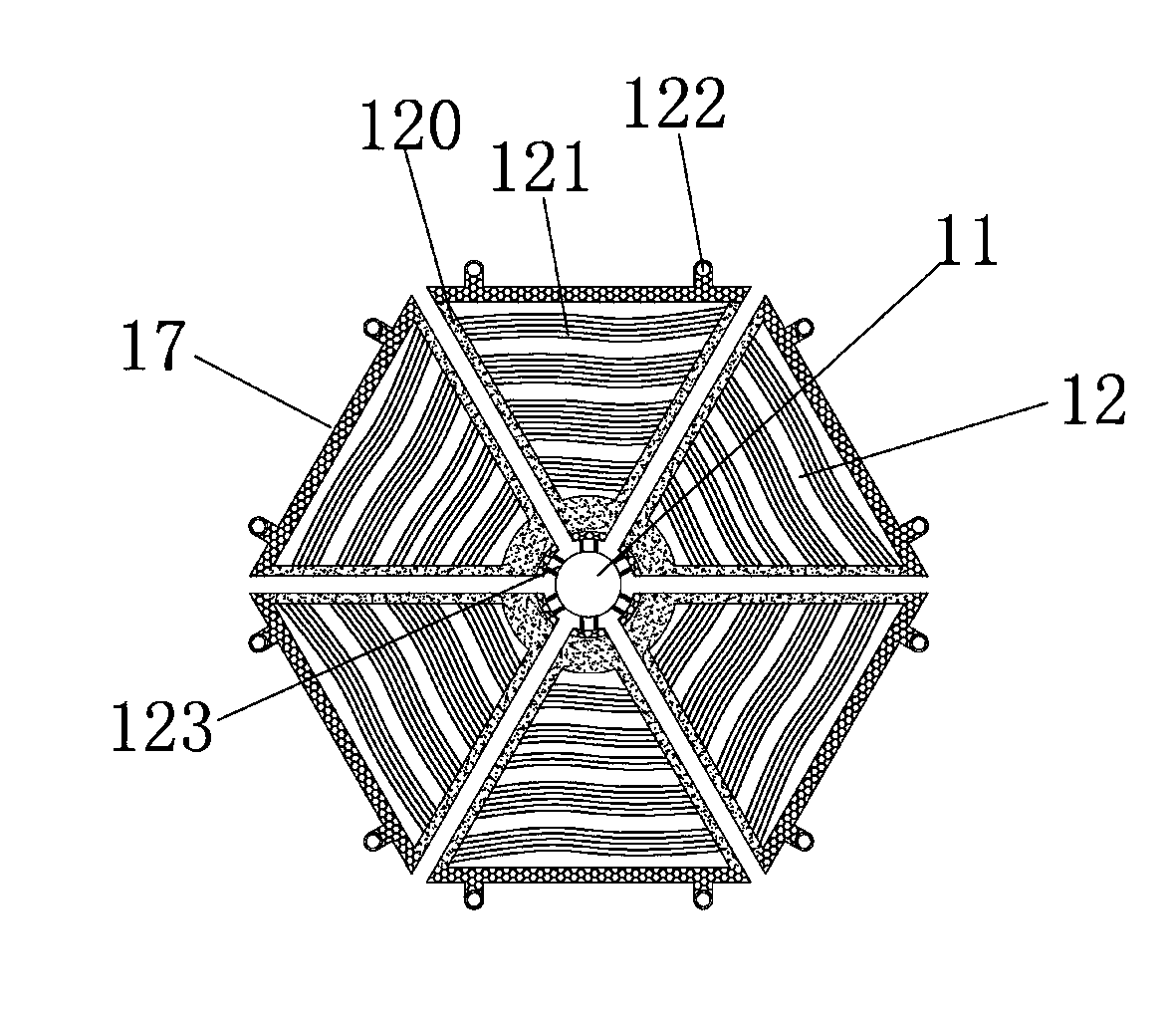

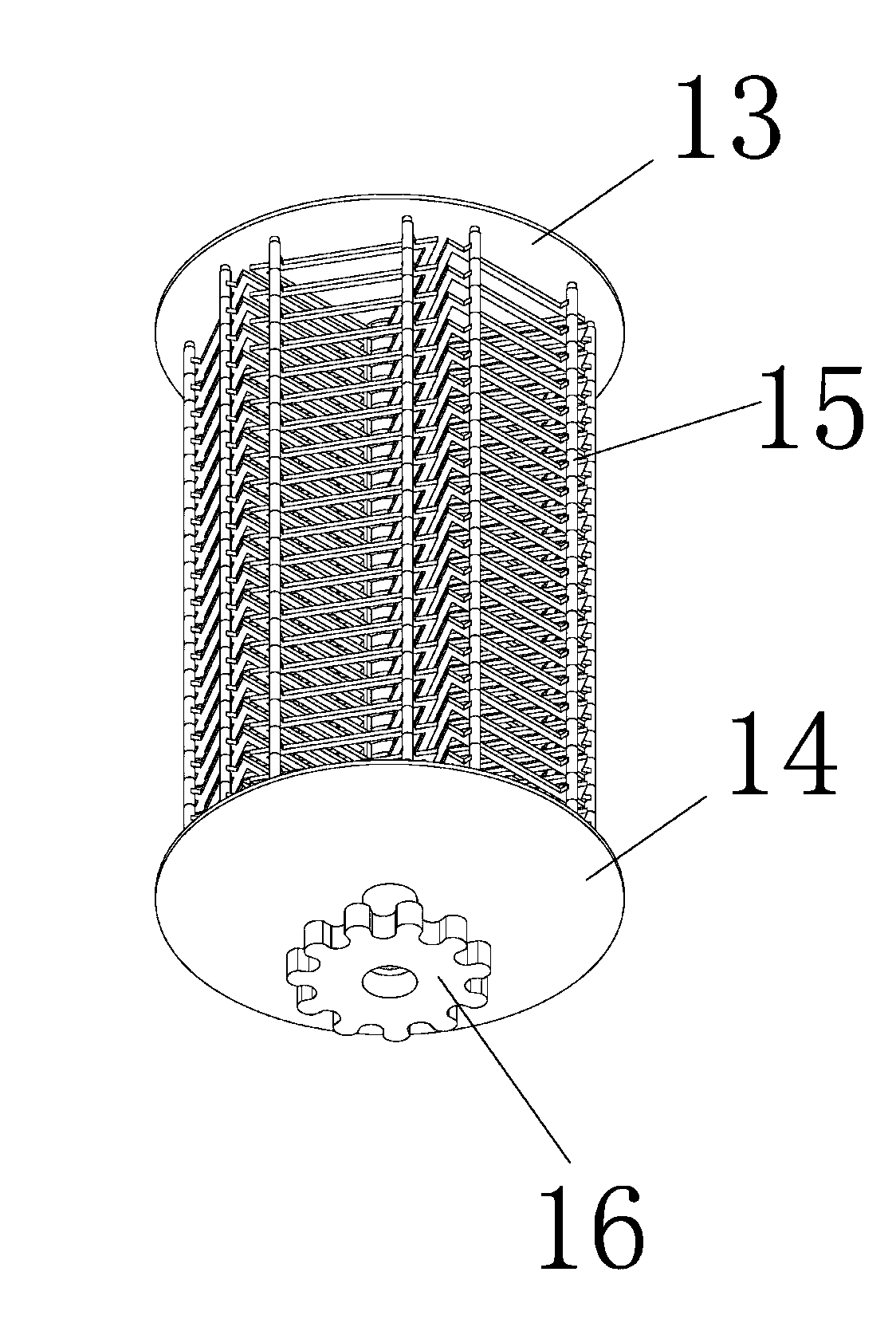

[0020] Such as figure 1 As shown, a fan-shaped rotary membrane separation device includes a central water collecting pipe 11, an upper tray 13 and a lower tray 14, and one end of the central water collecting pipe 11 is provided with a transmission gear 16, and the upper tray 13 and the lower tray 14 are arranged There are a plurality of turntables 17, and the turntable 17 is made up of at least six fan-shaped membrane modules 12, and the fan-shaped membrane modules are preferably 3-12. Filled with hollow fiber membrane filaments 121; the inside of the fan-shaped membrane module 12 is provided with a water outlet 123, the water outlet 123 is connected to the central water collection pipe 11, and the outside of the fan-shaped membrane module 12 is provided with two fixing holes 122, The outer circumference of the upper tray 13 and the lower tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com