Gas treating apparatus

A gas treatment and gas technology, applied in the field of gas decomposition and treatment devices, to achieve safe and reliable detoxification treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

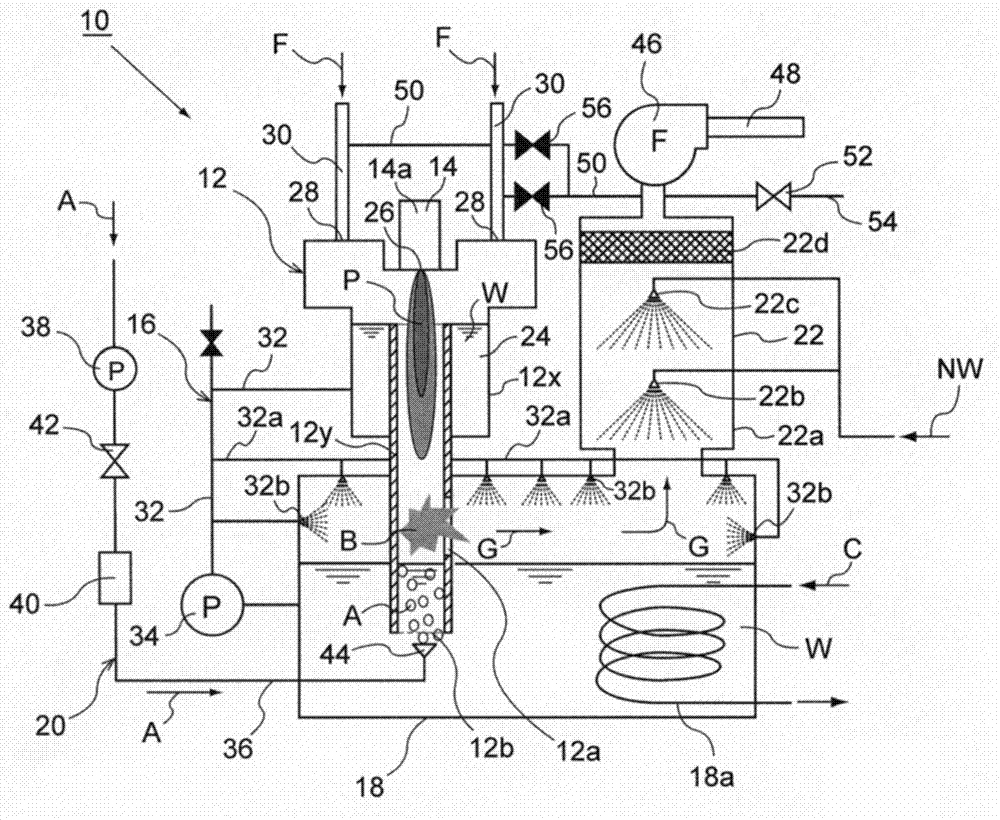

[0042] Hereinafter, the present invention will be described based on the illustrated embodiments. figure 1 It is a block diagram showing the outline of the gas processing apparatus 10 of this embodiment. As shown in the figure, the gas treatment device 10 of this embodiment is roughly composed of a reactor 12, a plasma generator 14, a water supply unit 16, a water tank 18, an oxidizing gas supply unit 20, a post-stage wet scrubber 22, and the like. In addition, this embodiment shows the case where the plasma generator 14 is used as a heat source, but the heat source used in the gas treatment device 10 is not limited to this device, and although not shown, a flame burner or an electric heater may also be used.

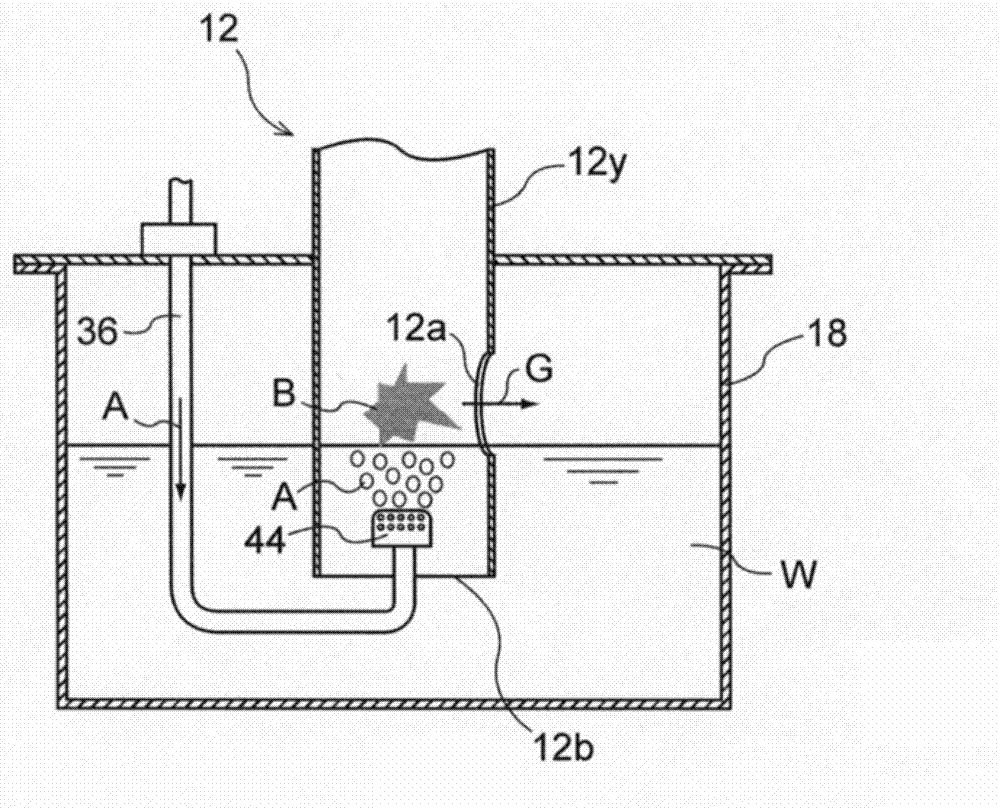

[0043] The reactor 12 is a device for enclosing the atmospheric pressure plasma P generated by the plasma generator 14 and the processing target gas F, and thermally decomposing the processing target gas F inside it. Layer pipe: a cylindrical outer cylinder 12x, whose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com