Electrostatic comb resonator

A technology of resonators and comb teeth, which is applied in the field of design and manufacture of MEMS devices, can solve problems such as structural warping and affecting the normal operation of resonators, and achieve the effects of reducing thermal noise of resistors, flexible wiring connections, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings.

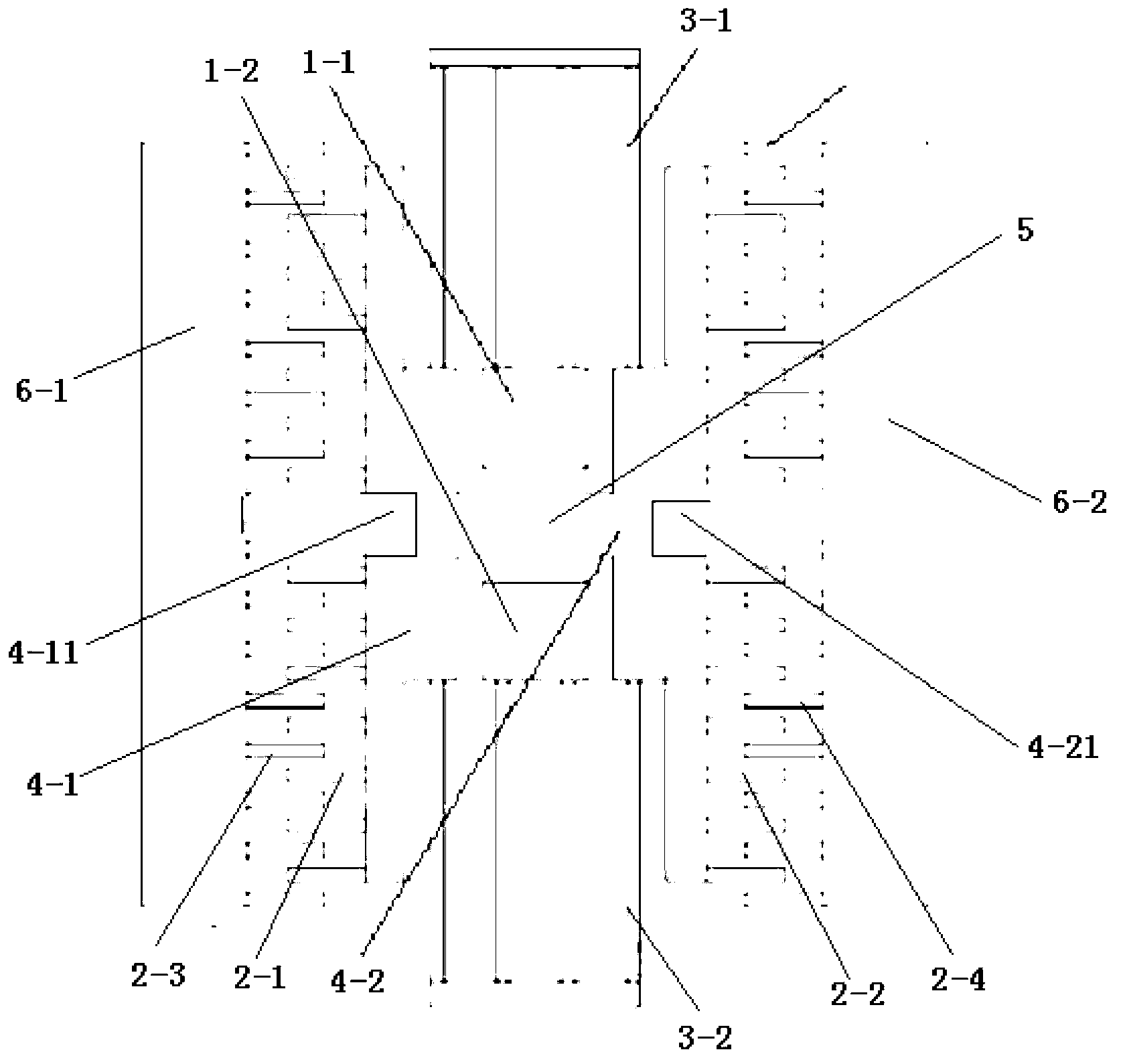

[0030] Such as figure 1 As shown, the electrostatic comb resonator of the present invention includes a substrate 7 and a structural layer on the substrate 7, and the structural layer includes an upper anchor point 1-1, a lower anchor point 1-2, a first interdigital capacitor 2-1, a second Second finger capacitor 2-2, third finger capacitor 2-3, fourth finger capacitor 2-4, upper elastic beam 3-1, lower elastic beam 3-2, vibrator mass, left anchor point 6-1 and the right anchor point 6-2, the left anchor point 6-1 and the right anchor point 6-2 are in the shape of a rectangular block, the upper anchor point 1-1 and the lower anchor point 1-2 are in the shape of a block; the quality of the vibrator The block includes a left mass block 4-1 and a right mass block 4-2, and the left mass block 4-1 and the right mass block 4-2 are connected by a connecting beam 5; the upper elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com