Ultrasonic storage battery

A battery and lead-acid battery technology, applied in secondary batteries, circuits, secondary battery repair/maintenance, etc., can solve problems such as electrolyte density lower than normal value, failure, and battery failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

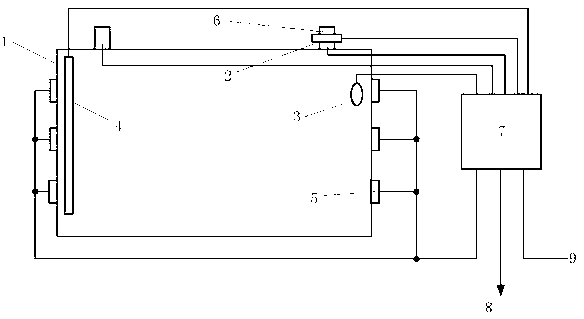

[0014] An ultrasonic storage battery, in which a specific gravity sensor 3 and a liquid level sensor 4 for measuring electrolyte parameters are installed inside a conventional lead-acid storage battery 1, a current sensor 2 is installed at the lower part of the storage battery terminal 6, and an ultrasonic transducer 5 is installed on the side of the storage battery 1 , the specific gravity sensor 3, the liquid level sensor 4, the current sensor 2 and the ultrasonic transducer 5 are all connected to the controller 7 through wires, the controller 7 is connected to the external isolated power supply 9, and the external isolated power supply 9 provides energy to it, and the controller 7. Transmit the data of the accumulator to the outside through the data bus 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com